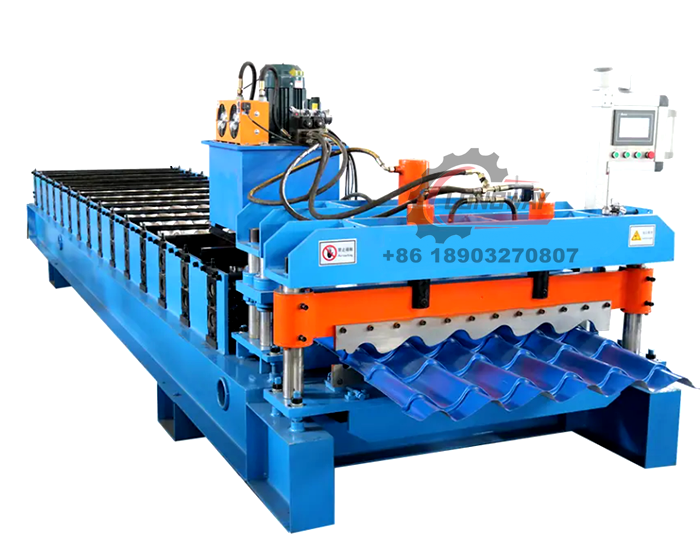

keel roll forming machine supplier

The Role of Keel Roll Forming Machines in Modern Manufacturing

In the ever-evolving landscape of manufacturing technology, keel roll forming machines have emerged as essential equipment for creating robust structural components used in various industries. These machines are instrumental in producing continuous profiles with superior precision, enabling manufacturers to meet specific design and engineering requirements. This article highlights the significance, functionality, and advantages of keel roll forming machines, particularly when sourced from reputable suppliers.

What is a Keel Roll Forming Machine?

A keel roll forming machine is a type of industrial equipment designed to shape metal sheets into specific cross-sectional profiles, which are often used as keels in construction, automotive, and other applications. The process involves feeding flat metal sheets into the machine, where rollers gradually shape the material into a desired profile through a series of bending operations. The finished product is typically characterized by its strength, durability, and lightweight properties, making it ideal for structural support.

Key Features of Keel Roll Forming Machines

1. Versatile Design Keel roll forming machines can produce a variety of profiles, including C, U, and Z sections, making them highly versatile for different applications. This flexibility allows manufacturers to cater to diverse market demands without investing in multiple machines.

2. High Precision One of the standout features of keel roll forming machines is their ability to achieve high precision in forming profiles. Advanced technology and computerized controls enable accurate measurements and shapes, ensuring that the final products conform to stringent industry standards.

3. Efficiency and Speed Keel roll forming machines are designed for high productivity, often operating at impressive speeds while maintaining accuracy. This efficiency translates into reduced lead times and increased output, which is crucial for manufacturers facing tight deadlines.

4. Durability and Low Maintenance Built from high-quality materials, these machines are designed to endure the rigors of daily operation. Their robust construction minimizes downtime, while requiring relatively low maintenance compared to other manufacturing equipment.

keel roll forming machine supplier

Benefits of Sourcing from Reliable Suppliers

Choosing the right supplier for keel roll forming machines is vital for ensuring quality and performance. Reputable suppliers often provide machines that undergo rigorous quality control and testing before they reach customers. Here are several benefits of sourcing from trustworthy manufacturers

1. Expertise and Support Established suppliers typically possess extensive industry knowledge. They can offer consultation and technical support, helping manufacturers select the right machine based on their specific needs.

2. After-sales Service Reliable suppliers provide comprehensive after-sales service, including installation, training, and maintenance. This support is crucial for helping manufacturers maximize the capabilities of their machines and reduce the learning curve.

3. Customization Options Leading manufacturers often offer customization services, where they tailor machines to meet unique production requirements. This customization ensures that businesses can optimize their manufacturing processes effectively.

4. Cost-effectiveness While it may be tempting to opt for lower-priced machines, investing in high-quality equipment from reputable suppliers often proves more cost-effective in the long run. Reduced breakdowns, lower maintenance costs, and increased productivity can lead to significant savings.

Conclusion

As the demand for high-quality structural components continues to grow, keel roll forming machines have become indispensable tools in modern manufacturing. Their ability to produce precise, durable profiles efficiently makes them an excellent choice for various industries. By partnering with reliable suppliers, manufacturers can ensure they acquire the best equipment tailored to their specific needs, ultimately leading to enhanced productivity and competitiveness in the market. Embracing this technology will not only refine production processes but also contribute to the advancement of the manufacturing industry as a whole.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025