Exporter of High-Quality IBR Sheet Roll Forming Machines for Efficient Production

The Rise of IBR Sheet Roll Forming Machine Exporters

In today's fast-paced construction and manufacturing industries, efficiency and quality are paramount. One critical component of modern building materials is the IBR (Inverted Box Rib) sheet, which has gained significant popularity due to its exceptional durability and aesthetic appeal. To produce these high-quality sheets, the industry relies heavily on specialized machinery known as IBR sheet roll forming machines. As global demand for these machines surges, the role of IBR sheet roll forming machine exporters becomes increasingly significant.

Understanding IBR Sheet Roll Forming Machines

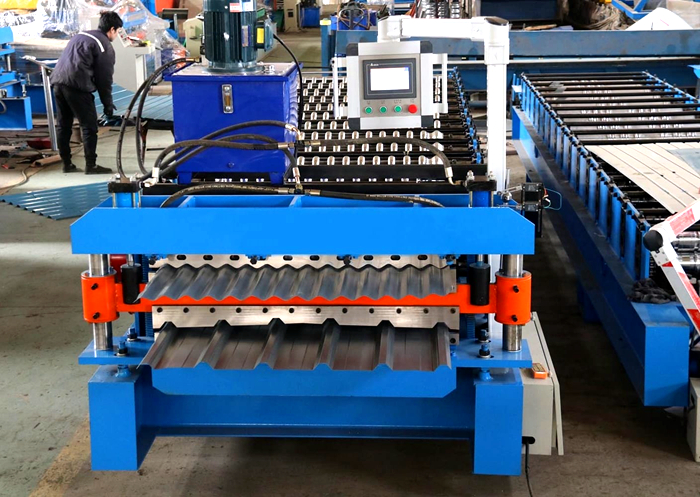

IBR sheet roll forming machines are used to convert flat metal sheets into profiled sheets with box rib patterns. The process involves feeding a continuous metal strip through a series of rollers, which gradually shape the material into the desired form. The quality of the finished product is largely determined by the precision and efficiency of the forming machine. Key features of these machines include customizable roller designs, automated controls, and the ability to work with various materials, including galvanized steel and aluminum.

The Global Market Demand

The construction industry is witnessing a significant boom, particularly in developing countries where urbanization is at an all-time high. This has led to increased demand for IBR sheets due to their cost-effectiveness and durability. IBR sheets are commonly used for roofing and wall cladding in both residential and commercial buildings. Their ability to withstand harsh weather conditions makes them an ideal choice for construction in diverse climates. Consequently, IBR sheet roll forming machine exporters are capitalizing on this demand, expanding their reach to international markets.

Exporting Opportunities

As the market for IBR sheets grows, so too does the opportunity for exporters of roll forming machines. Many manufacturers are seeking to upgrade their existing equipment or invest in new machinery to meet the demands of their local markets. This trend is particularly noticeable in countries in Africa, Asia, and South America, where infrastructural development projects are on the rise. Exporters are not just selling machines; they are offering solutions that help businesses increase productivity and ensure quality output.

ibr sheet roll forming machine exporter

Factors Influencing Exports

Several factors influence the success of IBR sheet roll forming machine exporters in the global market. Quality and reliability of machines are paramount; businesses are cautious about investing in equipment that doesn’t deliver consistent results. As such, exporters must prioritize manufacturing high-quality machines that adhere to international standards.

Another critical aspect is after-sales support. Exporters who offer comprehensive customer service, including installation, maintenance, and training, are more likely to build strong relationships with their clients. Furthermore, understanding regional market needs, such as localized designs and compliance with building codes, can significantly enhance an exporter’s competitiveness in the market.

Innovations and Technological Advancements

The evolution of technology plays a crucial role in the development of IBR sheet roll forming machines. Innovations such as computer numerical control (CNC) systems allow for greater customization and precision in production. Additionally, advancements in materials technology enable the creation of lighter and more durable machines. Exporters who invest in research and development are well-positioned to lead the market and gain competitive advantages.

Conclusion

The role of IBR sheet roll forming machine exporters is becoming increasingly vital in response to the growing global demand for IBR sheets. By focusing on quality, providing exceptional customer service, and embracing technological advancements, these exporters can thrive in a competitive landscape. As the construction industry continues to evolve, the relationship between equipment manufacturers and builders will be crucial in shaping the future of building materials, ensuring that they meet the needs of modern architecture and construction methods. The journey of IBR sheet roll forming machine exporters is just beginning, and their impact on the industry will be felt for years to come.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025