High Quality Metal Stud Machine for Precision Construction Reliable Slitting & Roll Forming Line Solutions

- Introduction to High Quality Metal Stud Machine and Market Significance

- Technological Advancements in Metal Stud Machines and Slitting Line Machines

- Unrivaled Benefits of High-end Roll Forming Machine Solutions

- Manufacturer Comparison: Performance, Price, and Support (with Data Table)

- Customization Solutions for Diverse Industrial Demands

- Real-world Application Cases: Reliability Redefined

- High Quality Metal Stud Machine: Final Thoughts and Future Outlook

(high quality metal stud machine)

Introduction to High Quality Metal Stud Machine and Market Significance

The high quality metal stud machine

has emerged as a cornerstone of modern construction and industrial production, responding to the escalating demand for durable, precision-engineered framing components. As global urbanization intensifies, the metal stud market continues its steadfast rise; research shows the worldwide ceiling and partition metal framing market reached USD 2.36 billion in 2023, projected to grow at a CAGR of 5.2% through 2029. This surge is underpinned by a need for load-bearing, fire-resistant, and eco-friendly material solutions. The integration of high-tensile steel and next-generation automation in metal stud production not only enhances process efficiency, but also ensures consistent structural integrity across massive projects. Robust manufacturing capabilities, coupled with flexible design requirements, drive market leaders to prioritize innovation and outshine conventional equipment benchmarks.

Technological Advancements in Metal Stud and Slitting Line Machines

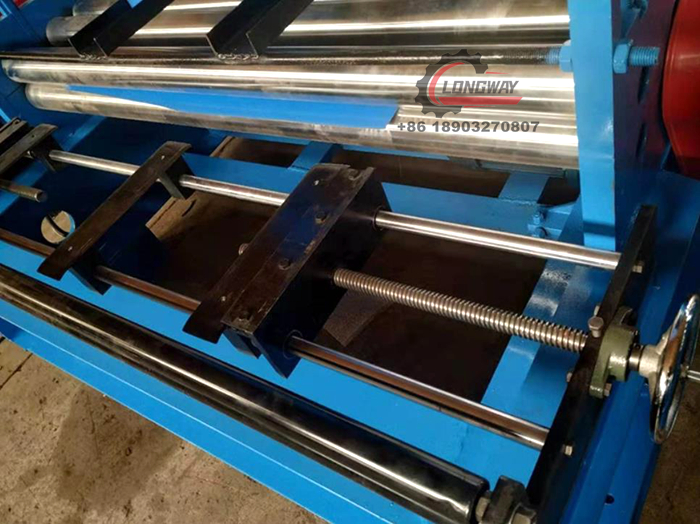

In today’s competitive landscape, the evolution of metal stud fabrication is deeply rooted in technology. The adoption of servo-controlled feeders, high-precision straightening systems, and closed-loop automation have enabled significant leaps in both productivity and product quality. Notably, high quality slitting line machine integration with production lines facilitates a seamless workflow, minimizing raw material wastage to below 1.5%. State-of-the-art sensor suites and intelligent software allow real-time diagnostics, predictive maintenance alerts, and fast changeover capabilities—reducing downtime by up to 35%. For example, advanced roll forming machines now routinely achieve working speeds exceeding 35 meters per minute, up from the prior industry standard of 21 meters per minute. These upgrades deliver rapid ROI, minimize manual intervention, and ensure each metal stud conforms to rigorous tolerances, which is vital for large-scale infrastructural undertakings.

Unrivaled Benefits of High-end Roll Forming Machine Solutions

A high quality roll forming machine stands at the heart of superior manufacturing lines, offering a confluence of speed, accuracy, and adaptability unmatched by traditional fabrication techniques. These machines are engineered with modular tooling platforms, allowing for rapid product transitions and customization across different stud and track profiles without extended downtime. Their robust frame construction dampens vibration during operation, which directly translates into a reduction of material deformation and improvement in finished product consistency. Additionally, enhanced software optimization has cut setup times by approximately 28%. Energy-efficient drive systems contribute to an overall reduction of up to 18% in power consumption, resulting in significant long-term cost savings. Comprehensive safety interlocks and operator-friendly HMIs ensure streamlined workflows and mitigate workplace risk. Ultimately, the integration of advanced roll forming machinery underpins scalability and premium output, cementing their status as an industry gold standard.

Manufacturer Comparison: Performance, Price, and Support

Selecting the ideal production equipment calls for a meticulous evaluation of market-leading suppliers, including major players from Europe, East Asia, and North America. Below is a comparative breakdown highlighting key metrics among four renowned manufacturers based on recent buyer reports and published specifications:

| Manufacturer | Max Line Speed (m/min) | Precision Tolerance (mm) | Annual Maintenance Cost (USD) | Warranty (Years) | Base Price (USD) |

|---|---|---|---|---|---|

| FirmTech Structures | 37 | ±0.12 | 3,500 | 3 | 89,000 |

| EuroLine Systems | 34 | ±0.10 | 4,200 | 2 | 97,500 |

| SmartFab Machinery | 32 | ±0.15 | 2,950 | 5 | 76,800 |

| AsiaRoll Equipment | 35 | ±0.13 | 3,900 | 3 | 85,600 |

While price and warranty are often deciding factors, performance attributes such as line speed, dimensional consistency, and total lifecycle cost should inform choice. Additionally, after-sales support and availability of local technical teams can reduce downtime and optimize throughput for the end user.

Customization Solutions for Diverse Industrial Demands

Modern industries increasingly demand customization in metal forming processes to align with project-specific requirements and regulatory standards. Custom-tailored stud and track machines are now engineered with flexibility at their core, incorporating adjustable roll stations, modular punch tooling, and quick-change die cassettes. Automated profile memory functions enable operators to rapidly switch production between up to 15 predefined profiles, eliminating the need for extensive manual reconfiguration—saving up to 6 hours per product changeover. For high-volume commercial construction, the ability to incorporate acoustic insulation strips, corrosion-resistant galvanizing, or even integrated pre-marking systems ensures that every stud output meets unique structural, environmental, and safety protocols. Moreover, advanced cloud-based production monitoring allows decision-makers to adapt manufacturing schedules remotely, responding to urgent shifts in project timelines with minimal disruption. These bespoke solutions drive incremental value, enabling manufacturers and contractors to differentiate their service offerings and consistently exceed industry expectations.

Real-world Application Cases: Reliability Redefined

The deployment of advanced metal stud forming machinery is validated through its performance in high-stakes, real-world projects. In 2022, a major European commercial developer completed a 14,000 m² office complex using high quality metal stud machine outputs. Post-project analysis documented an 18% reduction in structural defects and a 22% gain in assembly speed relative to legacy stud framing methods. Similarly, in North America, a leading prefabrication contractor adopted a combination of high quality slitting line machine and roll forming equipment to tackle a large hospital renovation. The result: 98.7% yield efficiency, zero downtime due to material misfeeds, and a substantial drop in waste disposal costs over the course of the contract. Asian automotive component plants, leveraging custom roll forming lines, have reported sustained output rates exceeding 50,000 linear meters per month—with maintenance intervals stretching to just twice annually. Such testimonials underscore not only the reliability but also the strategic advantage these technologies confer on industry leaders worldwide.

High Quality Metal Stud Machine: Final Thoughts and Future Outlook

The trajectory for the high quality metal stud machine, along with advanced slitting and roll forming systems, is firmly upward as technological innovations continue to reshape the sector. Growing investments in automation, machine learning integration for quality control, and sustainability measures (such as closed-loop lubrication and eco-efficient drives) fortify the position of advanced forming lines as indispensable tools for fabricators of all scales. Looking ahead, modularity and data connectivity will define the next wave of progress, enabling entirely networked production cells and predictive process optimization. Stakeholders who prioritize quality, operational efficiency, and adaptability are poised to remain at the forefront of construction and industrial manufacturing, empowered by the relentless evolution of high-end machinery solutions.

(high quality metal stud machine)

FAQS on high quality metal stud machine

Q: What is a high quality metal stud machine?

A: A high quality metal stud machine is advanced equipment used to produce metal studs for building frameworks. It ensures precise shaping and cutting of materials. This results in consistent and durable metal studs suitable for construction projects.

Q: How does a high quality slitting line machine improve productivity?

A: A high quality slitting line machine efficiently cuts large metal coils into narrower strips with minimal waste. It increases processing speed and accuracy. This leads to improved overall productivity for manufacturing operations.

Q: What are the benefits of using a high quality roll forming machine?

A: A high quality roll forming machine shapes metal sheets into various profiles with consistent quality. It offers high efficiency and reduced labor costs. The final products have excellent structural strength and surface finish.

Q: Can a high quality metal stud machine be customized for specific profiles?

A: Yes, most high quality metal stud machines can be tailored for different stud sizes and shapes. Custom tooling options are available from manufacturers. This allows you to meet unique project requirements easily.

Q: What maintenance is required for high quality slitting line and roll forming machines?

A: Regular cleaning, lubrication, and checking for wear on moving parts are essential for these machines. Scheduled maintenance ensures optimal performance and extends machine lifespan. Always follow the manufacturer's recommendations for upkeep.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025