cut to length line manufacturers

Understanding Cut-to-Length Line Manufacturers

In the manufacturing industry, efficiency and precision are critical components that drive productivity and profitability. One of the processes that have gained significant attention in recent years is the cut-to-length (CTL) line. This operation involves taking a coil of material—often metals like steel or aluminum—and cutting it into predetermined lengths. Given the increasing demand for customized lengths across various sectors, cut-to-length line manufacturers play a pivotal role in facilitating this process.

What is a Cut-to-Length Line?

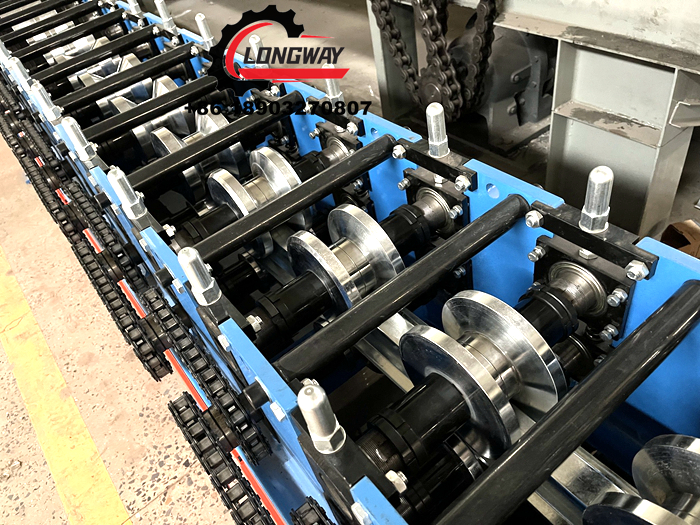

A cut-to-length line is a system designed to convert large rolls of material into smaller, manageable pieces efficiently. The process typically involves several key stages, including uncoiling, straightening, shearing, and stacking. Each of these stages requires precise machinery and control systems to ensure that the final product meets the specified length and tolerances.

Key Features of Cut-to-Length Lines

1. High Precision One of the primary characteristics of a CTL line is its ability to produce high-precision cuts. Manufacturers invest in advanced technology, including lasers and automated measuring systems, to achieve exact tolerances.

2. Speed CTL lines are designed for speed. High throughput rates are essential for meeting the demands of various industries, including automotive, construction, and appliance manufacturing.

3. Versatility Modern CTL lines can handle a wide range of materials, from thin sheets to thicker plates, accommodating different sizes and specifications.

4. Automation Many cut-to-length lines incorporate automation to enhance efficiency and reduce labor costs. This includes automated stackers and conveyors, minimizing the need for manual handling.

5. Customization Manufacturers can often customize CTL lines to suit specific production needs, allowing for a better fit in unique operational settings.

Market Trends and Innovations

cut to length line manufacturers

The market for cut-to-length lines has expanded significantly, driven by several factors. The rise of e-commerce and the need for just-in-time delivery has led to increased demand for precision manufacturing. As industries strive to enhance their production capabilities, the emphasis on tailored solutions has never been greater.

Moreover, technological innovations are transforming the CTL landscape. Manufacturers are increasingly adopting Industry 4.0 practices, integrating IoT devices and data analytics to optimize operations. This shift allows for real-time monitoring and predictive maintenance, reducing downtime and extending the lifespan of equipment.

Selecting a Cut-to-Length Line Manufacturer

When choosing a CTL line manufacturer, several factors should be considered

1. Experience and Reputation An established manufacturer with a proven track record can offer insights into the reliability and quality of their equipment.

2. Customization Options Each manufacturing operation is unique. A manufacturer that offers tailored solutions can better meet specific production needs.

3. Support and Service Post-sale support is crucial. Look for manufacturers that provide comprehensive training, maintenance, and troubleshooting assistance.

4. Technology Evaluate the type of technology used in their systems. Advanced machinery can lead to improved accuracy and reduced waste.

5. Cost-Efficiency While initial cost is important, consider the long-term value of the equipment regarding maintenance, energy consumption, and productivity gains.

Conclusion

Cut-to-length line manufacturers are vital players in the modern manufacturing landscape. By providing efficient, high-precision cutting solutions, they enable businesses to meet the diverse needs of their customers. As technology continues to evolve, the capability and performance of CTL lines will only improve, allowing manufacturers to adapt to the ever-changing market conditions. In a world where customization and efficiency are paramount, investing in reliable cut-to-length solutions can give businesses the competitive edge they need to thrive. With the right partner, manufacturers can ensure their operations are both productive and profitable, navigating the complexities of modern manufacturing with ease.

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025