Custom Standing Seam Roof Machine Available for Purchase and More Options

Custom Standing Seam Roof Machine for Sale Revolutionizing Roofing Solutions

When it comes to roofing, the quality of materials and the efficiency of installation processes can significantly impact a structure's durability and aesthetic appeal. One innovative solution gaining traction in the construction industry is the custom standing seam roof machine. This machine is designed specifically for creating standing seam roofs, a popular choice due to their superior weather resistance, longevity, and modern appearance. In this article, we’ll explore the benefits, features, and availability of custom standing seam roof machines for sale.

Understanding Standing Seam Roofs

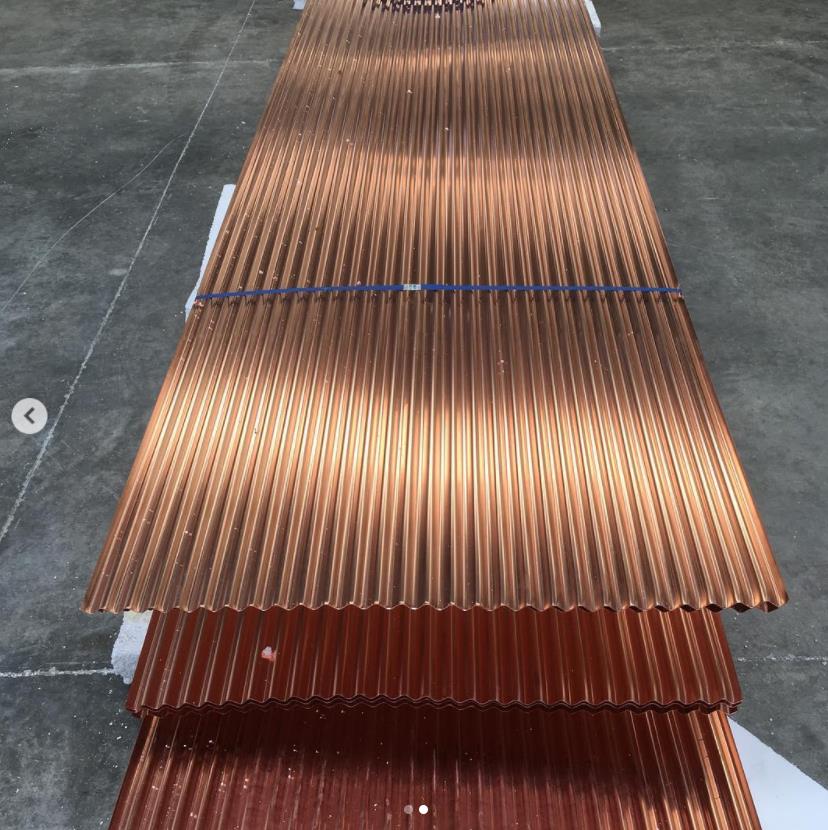

Standing seam roofs consist of vertical panels with interlocking seams that run vertically along the roof slope. This design not only enhances the building's visual appeal but also provides excellent protection against the elements. The raised seams create a water-resistant barrier, preventing leaks and water infiltration, which is particularly beneficial in regions with heavy rainfall or snow. Additionally, standing seam roofs are typically made from materials like steel or aluminum, offering both strength and lightweight properties.

Why Invest in a Custom Roof Machine?

Investing in a custom standing seam roof machine enables contractors and roofing companies to gain a competitive edge in the market. Here are some compelling reasons to consider

1. Tailored Solutions A custom machine can be designed to meet specific project requirements, including panel widths, height variations, and materials used. This customization allows for greater flexibility in responding to client needs.

2. Cost Efficiency By producing standing seam panels in-house, companies can significantly reduce material waste and labor costs. This leads to increased profit margins and the ability to offer more competitive pricing to clients.

custom standing seam roof machine for sale

3. Increased Productivity A standing seam roof machine streamlines the production process, allowing for faster turnaround times. This efficiency proves invaluable during peak construction seasons when time is of the essence.

4. Quality Assurance With the ability to oversee the manufacturing process, contractors can ensure that each panel meets the highest quality standards. This level of control helps in minimizing errors and ensuring consistency across projects.

Key Features of a Custom Standing Seam Roof Machine

When searching for a standing seam roof machine, there are several key features to consider. Look for machines that offer

- Durability Heavy-duty construction ensures longevity and reliable performance over time. - Ease of Use User-friendly controls and setup can drastically reduce training time for operators. - Versatility The ability to produce various profiles and thicknesses expands the machine's usability for different projects. - Portability Compact and lightweight designs can be advantageous for on-site production, minimizing transport costs.

Availability and Market Options

As the demand for standing seam roofing continues to rise, several manufacturers are offering custom standing seam roof machines for sale, catering to different business sizes and needs. It’s advisable to research and compare options, focusing on features, warranty, and customer support. By securing the right machinery, contractors can enhance their service offerings and solidify their position in the competitive roofing market.

In conclusion, the investment in a custom standing seam roof machine is not just a purchase; it's a strategic business move that can lead to improved efficiency, cost savings, and customer satisfaction. As the roofing industry evolves, embracing innovative solutions will be key to staying ahead of the curve. Whether you’re a seasoned contractor or a newcomer, a custom standing seam roof machine could be the cornerstone of your success in roofing projects.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025