ceiling t grid roll forming machine

The Ceiling T Grid Roll Forming Machine Revolutionizing Construction and Design

In the ever-evolving construction industry, efficiency, precision, and cost-effectiveness are paramount. One of the most innovative tools that have emerged to meet these demands is the Ceiling T Grid Roll Forming Machine. This advanced piece of equipment is designed specifically for producing T-shaped grid systems commonly used in suspended ceilings. With its innovative technology and design, this machine is revolutionizing how construction projects are approached—aiding in faster production times, increased accuracy, and reduced labor costs.

Understanding the Ceiling T Grid System

Before delving into the functionality of the roll forming machine, it is essential to understand the Ceiling T grid system itself. These grids are crucial for supporting ceilings and are typically made from lightweight materials such as steel or aluminum. They are installed in a grid-like pattern, which allows for the easy placement of ceiling tiles, lights, and other fixtures. The T shapes are essential for creating a suspended ceiling, providing the necessary support while allowing for ventilation and access to the space above.

The Role of Roll Forming Machinery

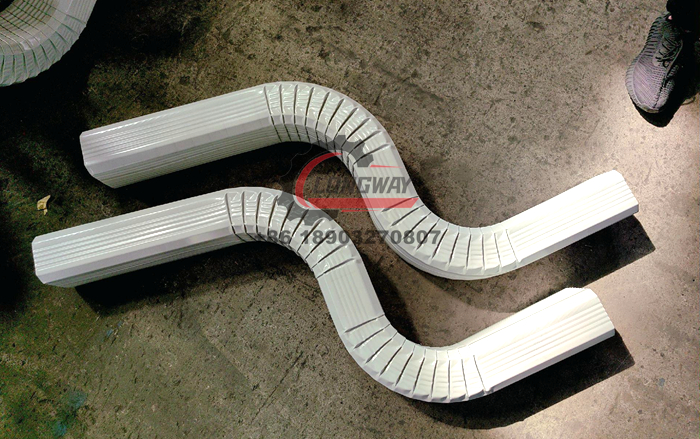

Roll forming is a continuous bending operation in which long strips of metal are gradually shaped and formed into desired profiles. The Ceiling T Grid Roll Forming Machine automates this process, significantly enhancing production rates and ensuring uniform quality. These machines feed metal coils through a series of rollers that incrementally shape the metal into the T grid profiles with high precision.

One of the standout features of these machines is their ability to produce customized dimensions. Depending on the project's specific requirements, manufacturers can alter the specifications of the grids, including width, height, and thickness. This flexibility is invaluable for contractors who require specific measurements to meet local building codes and client expectations.

Benefits of Using a Ceiling T Grid Roll Forming Machine

1. Increased Efficiency Traditional methods of fabricating ceiling grids can be time-consuming and labor-intensive. The roll forming machine drastically reduces the time required to produce these grids, enabling contractors to complete projects more quickly.

ceiling t grid roll forming machine

2. Precision Manufacturing The machine’s design ensures that every grid produced is uniform, meeting strict quality standards. This consistency is crucial in construction, where even minor discrepancies can lead to significant problems during installation.

3. Cost-Effectiveness By automating the production process, manufacturers can reduce labor costs and material wastage. The efficient use of materials results in lower overall expenses, which can be crucial for staying within budget on large-scale projects.

4. Enhanced Scalability With the ability to quickly switch between various profiles and sizes, businesses can easily scale operations to accommodate different project sizes or client demands. This adaptability allows manufacturers to stay ahead of market trends and customer needs.

5. Durability and Strength The machines can work with various materials, producing grids that are both lightweight and strong. This combination is essential for maintaining structural integrity while also providing ease of installation.

Future Prospects

As construction techniques continue to advance and the demand for suspended ceilings grows, the importance of efficient manufacturing systems like the Ceiling T Grid Roll Forming Machine will only increase. Innovations in technology, such as integration with smart manufacturing processes and improved energy efficiency, are likely to shape the future of these machines.

Moreover, the trend towards sustainable construction will prompt machine manufacturers to create equipment that not only maximizes material efficiency but also uses eco-friendly materials.

In conclusion, the Ceiling T Grid Roll Forming Machine represents a significant step forward in the construction industry, enhancing productivity, precision, and adaptability. As the industry continues to face new challenges, such as labor shortages and increasing demand for sustainable practices, this machinery stands out as a vital solution for the modern construction landscape.

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025