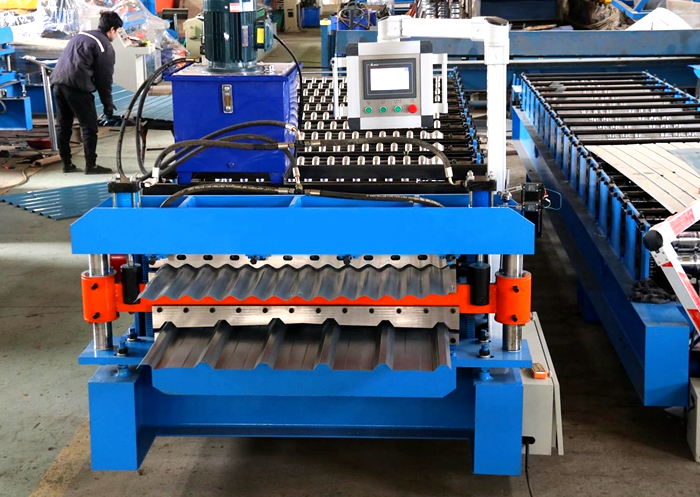

angle channel roll forming machine

The Angle Channel Roll Forming Machine An Overview

Roll forming is a highly efficient process used in the manufacturing industry to create a variety of metal shapes. Among the various types of roll forming machinery, the angle channel roll forming machine is particularly significant due to its versatility and precision in producing angle channels used in construction, manufacturing, and other sectors. This article delves into the working mechanisms, applications, and advantages of angle channel roll forming machines.

Understanding the Process

The angle channel roll forming machine operates by feeding a flat strip of metal into a series of rollers that gradually shape the material into the desired angle channel profile. The process begins with the alignment of the metal strip, which is then passed through a series of forming rolls. Each roller is specifically shaped to progressively bend the strip into the desired channel form—typically a 90-degree or other specified angle. The final product is a robust and uniform angle channel.

One of the most appealing features of angle channel roll forming machines is their capability to produce continuous lengths of channel. The machine can be adjusted to create various dimensions and specifications by changing the roller setups and speed settings, making them adaptable for different production runs. This flexibility allows manufacturers to meet diverse customer requirements efficiently.

Applications in Various Industries

Angle channel profiles are essential components in numerous industries. They are commonly used in construction for creating frames, structural supports, brackets, and joining components. In the manufacturing sector, these profiles serve a similar purpose, where they are employed in machinery, assembly structures, and various mechanical applications. Additionally, angle channels find uses in the automotive and aerospace industries for lightweight structural solutions.

The versatility of the angle channel roll forming machine means it can cater to a variety of materials, including mild steel, stainless steel, aluminum, and other alloys

. This adaptability enhances its appeal across sectors and lends itself to custom tooling for specific applications.angle channel roll forming machine

Advantages of Using Angle Channel Roll Forming Machines

1. High Efficiency The continuous process of roll forming means that large quantities of angle channel profiles can be produced in a shorter time than traditional machining methods. This efficiency is particularly beneficial for manufacturers with high volume requirements.

2. Material Optimization Roll forming minimizes material waste as it uses almost the entirety of the input strip to create finished products. This efficiency not only reduces costs but also contributes to environmentally-friendly manufacturing practices.

3. Consistent Quality The process allows for uniformity in the final products. The precision of roller settings ensures that each angle channel produced meets strict specifications, enhancing overall product quality.

4. Flexibility and Customization As mentioned, the angle channel roll forming machine can be customized to produce various profiles and dimensions. This flexibility allows companies to diversify their product offerings without the need for extensive machinery changes.

5. Cost-Effective While the initial investment in an angle channel roll forming machine can be significant, the long-term savings in labor, material wastage, and production time make it a cost-effective solution for many manufacturers.

Conclusion

The angle channel roll forming machine plays a crucial role in modern manufacturing processes, particularly for industries that rely on structural components. Its efficiency, flexibility, and quality control make it an invaluable asset in the production of angle channels. As industries continue to evolve and demand innovative solutions, the importance of such machinery will only grow, underlining the significant advancements in engineering and manufacturing technology. As we move into the future, these machines will undoubtedly play a pivotal role in shaping the infrastructures of tomorrow.

-

The Role of Hydraulic Systems in Sheet Metal SlittersNewsAug.23, 2025

-

Customization Options in Metal Deck Roll Forming MachinesNewsAug.23, 2025

-

Safety Tips When Using a Gutter Making MachineNewsAug.23, 2025

-

Key Components of a C Purlin Machine ExplainedNewsAug.23, 2025

-

Maintenance Tips for a Steel Angle Roll Forming MachineNewsAug.23, 2025

-

Portable Metal Roofing Machine Applications in Remote ConstructionNewsAug.23, 2025

-

Roof Panel MachineNewsAug.18, 2025