Affordable Prices for Roofing Sheets Manufacturing Machines in Today's Market

The Landscape of Roofing Sheets Manufacturing Machine Prices

In recent years, the demand for roofing sheets has soared, attributable to a booming construction industry and the increasing popularity of sustainable building materials. As more builders and homeowners seek durable, cost-effective roofing solutions, manufacturers have responded by introducing advanced roofing sheets manufacturing machines. Understanding the market landscape for these machines, especially regarding their prices, is essential for stakeholders in the construction and manufacturing industries.

What Are Roofing Sheets Manufacturing Machines?

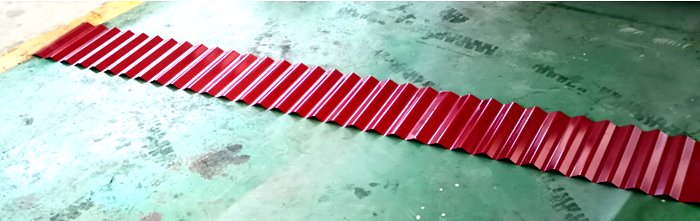

Roofing sheets manufacturing machines are specialized equipment designed to produce sheets used in roofing applications. These machines can create a variety of sheet profiles, such as corrugated, trapezoidal, and tile-like surfaces, catering to different aesthetic and functional requirements. The manufacturing process typically involves feeding raw materials, such as steel or aluminum, into the machine, which then rolls, cuts, and forms the sheet into the desired shape.

Factors Influencing Prices

The price of roofing sheets manufacturing machines can vary significantly based on several factors

1. Machine Type and Technology The type of machine—manual, semi-automatic, or fully automatic—plays a crucial role in pricing. Fully automatic machines, which offer higher production rates and efficiency, tend to be pricier. Furthermore, advancements in technology, such as improved automation and integration with computer controls, also affect costs.

2. Production Capacity Machines with higher production capacities are generally more expensive. Companies need to weigh their production needs against the initial investment. For example, a small-scale manufacturer may benefit from a lower-capacity, cost-effective machine, while larger enterprises might require more robust and expensive options.

3. Material Quality The quality of materials used in manufacturing the machines can influence prices as well. Machines built with high-grade steel and components tend to have longer lifespans and less maintenance downtime, making them a more strategic investment despite a higher initial cost.

roofing sheets manufacturing machine price

4. Brand Reputation Well-established manufacturers with a proven track record in producing reliable machinery often charge more for their products. Investing in a reputable brand may offer better after-sales support, warranty options, and overall machine reliability.

5. Location and Shipping Costs The geographic location of the manufacturer and the buyer can impact costs significantly. Import duties, regional market dynamics, and shipping logistics can all contribute to the overall price of the machinery.

Price Range Overview

On average, the prices for roofing sheets manufacturing machines can range from $20,000 to over $100,000. Entry-level models designed for small businesses might start around $20,000 to $30,000. In contrast, high-capacity, fully automatic systems can exceed $100,000, depending on the technology and features included.

Return on Investment

While the initial cost of a roofing sheets manufacturing machine may seem daunting, it is vital for buyers to consider the long-term return on investment (ROI). A high-quality machine can significantly increase production efficiency, minimize labor costs, and reduce waste, ultimately providing a better return over time.

Conclusion

In conclusion, the price of roofing sheets manufacturing machines is influenced by various factors, including machine type, production capacity, and technology. As demand for roofing sheets rises, understanding these dynamics will help manufacturers make informed decisions. Investing in the right machine not only affects immediate production capabilities but also shapes the long-term success of their business in a competitive market. Therefore, potential buyers should conduct thorough research, consider their unique needs, and evaluate all factors before making a purchase.

-

The Latest Trends in Cut to Length Equipment and MachinesNewsMay.09, 2025

-

Revolutionizing Door Frame Production: The Power of Modern MachinesNewsMay.09, 2025

-

Revolutionary Machines for Roller Shutter and Garage DoorsNewsMay.09, 2025

-

Everything You Need to Know About Gutter Roll Forming MachinesNewsMay.09, 2025

-

Efficiency in Coil Handling with Hydraulic Decoiler MachinesNewsMay.09, 2025

-

Downspout Roll Forming Machines and Their ValueNewsMay.09, 2025

-

Revolutionizing the Door Frame Industry: Key Insights on Roll Forming MachinesNewsApr.18, 2025