Nachricht

-

Extrusion moulding is used to form plastic or metal materials into a pre-defined shape. During the process, the material is melted and pushed through an extrusion moulding machine, forming a long, tube-like shape or rod. This is cooled and cut to the required length. Often, extrusion moulding plastic products created in this way are used for wiring or insulating applications.The products’ cross-sections show uniformity throughout the length of the tubing, which is highly prized for numerous projects. Extrude plastics can also be formed into other tubular products, such as drinking straws. The plastic can also be shaped into thin sheeting or films by being flattened out by a set of cooling rolls.Weiterlesen

Extrusion moulding is used to form plastic or metal materials into a pre-defined shape. During the process, the material is melted and pushed through an extrusion moulding machine, forming a long, tube-like shape or rod. This is cooled and cut to the required length. Often, extrusion moulding plastic products created in this way are used for wiring or insulating applications.The products’ cross-sections show uniformity throughout the length of the tubing, which is highly prized for numerous projects. Extrude plastics can also be formed into other tubular products, such as drinking straws. The plastic can also be shaped into thin sheeting or films by being flattened out by a set of cooling rolls.Weiterlesen -

At an initial glance, extrusion and injection molding may appear to be very similar manufacturing processes. Both processes send molten material through machines to mass-produce low-cost parts of the desired shape. Both are a continuous production processes that amortizes costs as one orders higher quantities of parts. But, as we will see, these similarities quickly disappear when examining the differences between extrusion and injection molding.Weiterlesen

At an initial glance, extrusion and injection molding may appear to be very similar manufacturing processes. Both processes send molten material through machines to mass-produce low-cost parts of the desired shape. Both are a continuous production processes that amortizes costs as one orders higher quantities of parts. But, as we will see, these similarities quickly disappear when examining the differences between extrusion and injection molding.Weiterlesen -

How do you determine what type of plastics manufacturer you should work with to design your custom plastic part? Forming plastic parts for industrial, commercial or medical uses requires different processes depending on the shape required and application of the product. Here’s the difference between plastic extrusion and injection molding.Weiterlesen

How do you determine what type of plastics manufacturer you should work with to design your custom plastic part? Forming plastic parts for industrial, commercial or medical uses requires different processes depending on the shape required and application of the product. Here’s the difference between plastic extrusion and injection molding.Weiterlesen -

Extrusion moulding is used to form plastic or metal materials into a pre-defined shape. During the process, the material is melted and pushed through an extrusion moulding machine, forming a long, tube-like shape or rod. This is cooled and cut to the required length. Often, extrusion moulding plastic products created in this way are used for wiring or insulating applications.The products’ cross-sections show uniformity throughout the length of the tubing, which is highly prized for numerous projects. Extrude plastics can also be formed into other tubular products, such as drinking straws. The plastic can also be shaped into thin sheeting or films by being flattened out by a set of cooling rolls.Weiterlesen

Extrusion moulding is used to form plastic or metal materials into a pre-defined shape. During the process, the material is melted and pushed through an extrusion moulding machine, forming a long, tube-like shape or rod. This is cooled and cut to the required length. Often, extrusion moulding plastic products created in this way are used for wiring or insulating applications.The products’ cross-sections show uniformity throughout the length of the tubing, which is highly prized for numerous projects. Extrude plastics can also be formed into other tubular products, such as drinking straws. The plastic can also be shaped into thin sheeting or films by being flattened out by a set of cooling rolls.Weiterlesen -

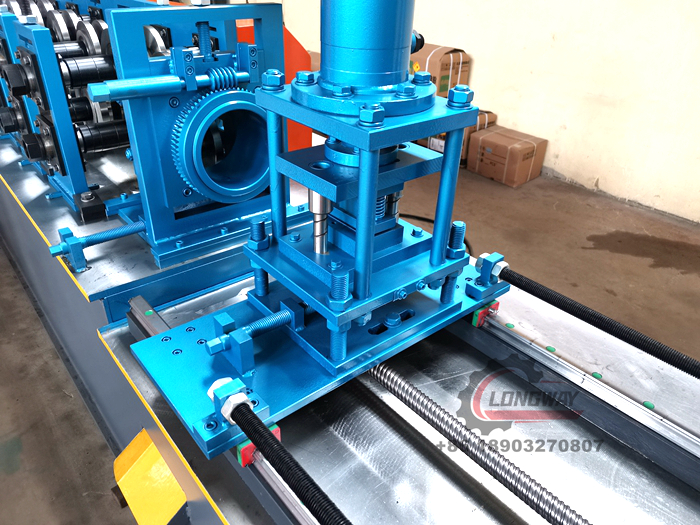

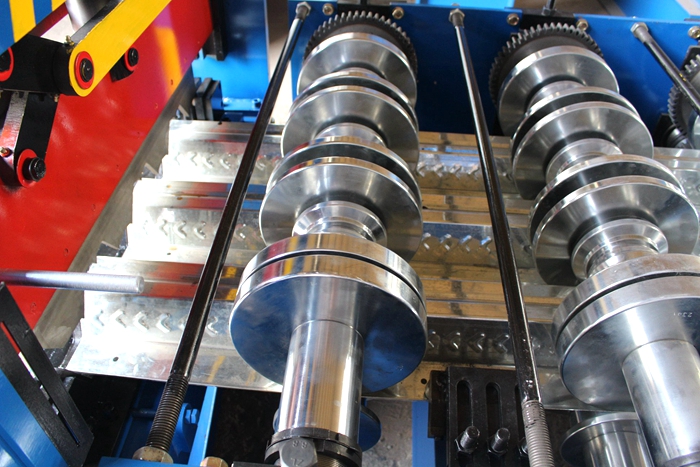

Roll forming machinery is a boon for both the quality and efficiency of metal fabrication. It allows for repeatable consistency within a product run, as well as versatility in design configurations and materials for metal parts. With wide-ranging applications from appliances and furniture to telecommunications and supports or frames for construction, this equipment produces large volumes of formed metal parts quickly, accurately, and affordably through consecutive bending stages.Weiterlesen

Roll forming machinery is a boon for both the quality and efficiency of metal fabrication. It allows for repeatable consistency within a product run, as well as versatility in design configurations and materials for metal parts. With wide-ranging applications from appliances and furniture to telecommunications and supports or frames for construction, this equipment produces large volumes of formed metal parts quickly, accurately, and affordably through consecutive bending stages.Weiterlesen -

Small-scale roll forming machines are specialized pieces of equipment making a big impact in cold-formed steel and construction — but are they worth it? Keep reading as we explain exactly how they work, plus the pros and cons, so you can make an informed decision if you’re considering a purchase.Weiterlesen

Small-scale roll forming machines are specialized pieces of equipment making a big impact in cold-formed steel and construction — but are they worth it? Keep reading as we explain exactly how they work, plus the pros and cons, so you can make an informed decision if you’re considering a purchase.Weiterlesen -

Roll forming is a metal fabrication process that involves the bending of metal strips to create a certain shape or design. It's one of the most simple and easy-to-understand metal forming processes there is; however, there are several components that go along with it.Once you learn about these components and the role they play in the metal fabrication process, you'll understand exactly how your roll formed part is made.Weiterlesen

Roll forming is a metal fabrication process that involves the bending of metal strips to create a certain shape or design. It's one of the most simple and easy-to-understand metal forming processes there is; however, there are several components that go along with it.Once you learn about these components and the role they play in the metal fabrication process, you'll understand exactly how your roll formed part is made.Weiterlesen -

So, you think you’re ready to purchase a portable roof panel machine, but have some questions or concerns? An excellent way to help you decide is to learn the reasons you may want to buy portable roof panel machines to see if they resonate with you and your business.Weiterlesen

So, you think you’re ready to purchase a portable roof panel machine, but have some questions or concerns? An excellent way to help you decide is to learn the reasons you may want to buy portable roof panel machines to see if they resonate with you and your business.Weiterlesen -

A continuous metal forming process passes a long metal strip through multiple rollers. These rollers are strategically configured to gradually shape the metal into the desired cross-sectional profile. One of the unique aspects of roll forming is that it allows for intricate shapes to be crafted without compromising the metal’s structural integrity.Weiterlesen

A continuous metal forming process passes a long metal strip through multiple rollers. These rollers are strategically configured to gradually shape the metal into the desired cross-sectional profile. One of the unique aspects of roll forming is that it allows for intricate shapes to be crafted without compromising the metal’s structural integrity.Weiterlesen -

What types of products can be produced using roll forming machines? Roll forming machines are versatile and can produce a wide range of products, including steel studs, roofing panels, metal channels, window frames, and automotive parts, among others.Weiterlesen

What types of products can be produced using roll forming machines? Roll forming machines are versatile and can produce a wide range of products, including steel studs, roofing panels, metal channels, window frames, and automotive parts, among others.Weiterlesen -

We have Roofing Sheet Making Machine. Metal roof sheets are an affordable option, able to withstand high temperatures. for this purpose, LOTOS roofing roll former offers to you Roofing Sheet Making Machine and Roof Panel Roll Forming Machine. in addition, A rolled metal roofing is lighter than a concrete or clay tile roof more durable than an asphalt shingle roof, and easier to handle than long-run metal roof tiles. furthermore, It is the best reliable and affordable roofing system in the marketplace in a range of designs and styles. moreover, Roof tiles can now mimic other roofing materials such as wood shake asphalt shingles, and slate, however, the metallic look often compromises the authenticity of these renditions and the overall design.Weiterlesen

We have Roofing Sheet Making Machine. Metal roof sheets are an affordable option, able to withstand high temperatures. for this purpose, LOTOS roofing roll former offers to you Roofing Sheet Making Machine and Roof Panel Roll Forming Machine. in addition, A rolled metal roofing is lighter than a concrete or clay tile roof more durable than an asphalt shingle roof, and easier to handle than long-run metal roof tiles. furthermore, It is the best reliable and affordable roofing system in the marketplace in a range of designs and styles. moreover, Roof tiles can now mimic other roofing materials such as wood shake asphalt shingles, and slate, however, the metallic look often compromises the authenticity of these renditions and the overall design.Weiterlesen -

Before launching into a series of articles detailing the different machine types, we realize an introduction to some basic concepts is in order. AMS Controls defines some common terms and jargon that are particular to the types of control systems we provide. This article covers the four basic machine application types very generally, describing functionality from a high level. A few pros and cons are listed, but each application will be covered in greater detail in subsequent articles.Weiterlesen

Before launching into a series of articles detailing the different machine types, we realize an introduction to some basic concepts is in order. AMS Controls defines some common terms and jargon that are particular to the types of control systems we provide. This article covers the four basic machine application types very generally, describing functionality from a high level. A few pros and cons are listed, but each application will be covered in greater detail in subsequent articles.Weiterlesen