студ . 20, 2025 05:34

Back to list

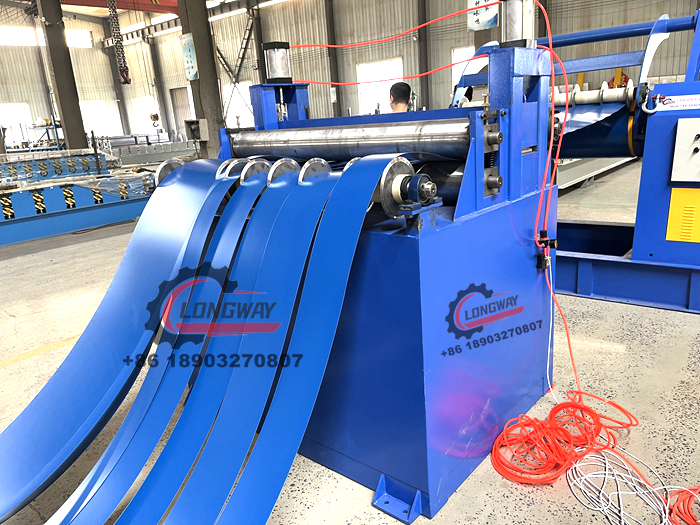

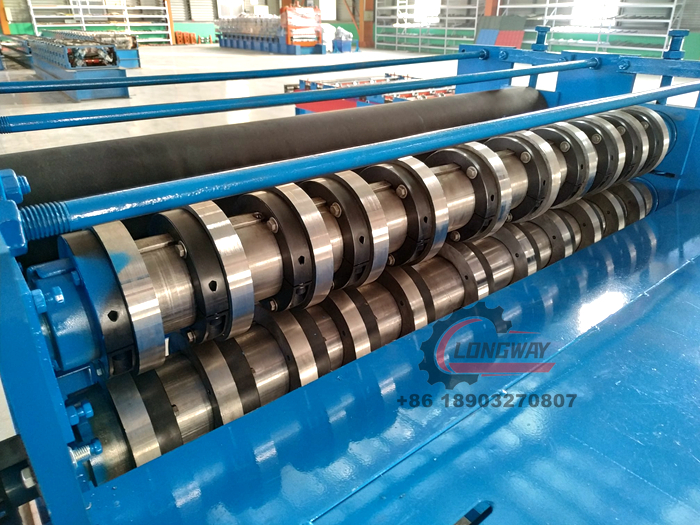

r panel roll forming machine for sale

Finding the perfect r panel roll forming machine for sale can be a transformative step for any business involved in sheet metal fabrication or construction. These machines are not just essential tools, but significant investments that can significantly impact operational efficiency and output quality. In this comprehensive exploration, we will delve into the intricate details that define high-quality r panel roll forming machines, offering insights based on hands-on experience and deep industry expertise.

Authoritativeness within this domain is often marked by brands with a proven track record of excellence. Established manufacturers who have demonstrated their commitment to quality through certifications, industry awards, and positive client testimonials should be given priority. Their reputation is typically backed by robust service networks and parts availability, which are crucial for minimizing downtime and ensuring that your machine remains operational at peak capacity over the long term. Trustworthiness is a critical factor when securing an r panel roll forming machine. Trustworthy sellers provide comprehensive warranties and detailed after-sales support, including training, maintenance, and troubleshooting services. These assurances are indispensable in fostering a long-term partnership, ensuring that your investment continues to yield returns through sustained machine performance and attendance to any operational hitches that may arise. Consider dealers who are transparent about machine provenance, including manufacturing details and previous usage, if purchasing second-hand equipment. In conclusion, choosing the right r panel roll forming machine is not merely a transaction but a strategic decision that influences your business’s capabilities and future growth. Prioritizing machines that blend cutting-edge technology with a proven history of reliability will position your enterprise at the forefront of roofing and panel fabrication. Always bear in mind the elements of experience, expertise, authoritativeness, and trustworthiness when evaluating potential purchases. By integrating these principles, you secure a sound investment that will elevate your production efficiency, quality, and, ultimately, your bottom line.

Authoritativeness within this domain is often marked by brands with a proven track record of excellence. Established manufacturers who have demonstrated their commitment to quality through certifications, industry awards, and positive client testimonials should be given priority. Their reputation is typically backed by robust service networks and parts availability, which are crucial for minimizing downtime and ensuring that your machine remains operational at peak capacity over the long term. Trustworthiness is a critical factor when securing an r panel roll forming machine. Trustworthy sellers provide comprehensive warranties and detailed after-sales support, including training, maintenance, and troubleshooting services. These assurances are indispensable in fostering a long-term partnership, ensuring that your investment continues to yield returns through sustained machine performance and attendance to any operational hitches that may arise. Consider dealers who are transparent about machine provenance, including manufacturing details and previous usage, if purchasing second-hand equipment. In conclusion, choosing the right r panel roll forming machine is not merely a transaction but a strategic decision that influences your business’s capabilities and future growth. Prioritizing machines that blend cutting-edge technology with a proven history of reliability will position your enterprise at the forefront of roofing and panel fabrication. Always bear in mind the elements of experience, expertise, authoritativeness, and trustworthiness when evaluating potential purchases. By integrating these principles, you secure a sound investment that will elevate your production efficiency, quality, and, ultimately, your bottom line.

Latest news

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

Related Products