лют . 20, 2025 07:49

Back to list

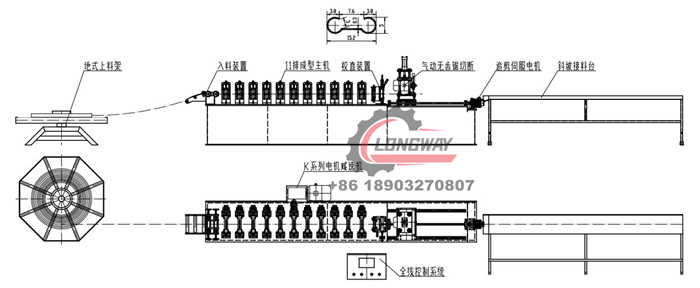

metal tile roof roll forming machine

Transforming the roofing industry, metal tile roof roll forming machines have steadily gained prominence due to their efficiency, versatility, and the quality of products they produce. A critical piece of equipment for anyone involved in metal roofing, these machines merge traditional craftsmanship with modern technology, providing unparalleled advantages for manufacturers and contractors alike.

Furthermore, the architectural benefits of metal roofing cannot be overstated. Metal tiles formed through these machines are not only durable and long-lasting but also aesthetically pleasing. They provide superior protection against the elements, displaying excellent resistance to wind, hail, and fire. As sustainability becomes increasingly important in construction, metal roofing stands out for its energy efficiency and recyclability, attributes that are gaining favor among environmentally conscious consumers and builders. Investing in a metal tile roof roll forming machine is a strategic decision that promises a high return on investment. The initial costs are balanced by the machine's long lifespan, low maintenance requirements, and the high-value output it facilitates. Moreover, the customizable nature of metal roofing tiles means that businesses can continuously adapt to market trends, ensuring their offerings remain relevant and appealing over time. In ensuring the best outcomes from these machines, choosing the right supplier is crucial. Prospective buyers should look for suppliers with established reputations, who offer rigorous quality controls and comprehensive after-sales support. This diligence will ensure the machine operates at peak efficiency, upholding its promise of precision and performance. In conclusion, metal tile roof roll forming machines are unrivaled assets in the metal roofing industry. These machines marry expertise with practicality, providing solutions that meet both traditional and modern roofing demands. By prioritizing quality, customer support, and innovation, manufacturers and suppliers affirm trustworthiness and authoritative expertise, essential qualities for success in a competitive marketplace. Through these dimensions—experience, expertise, authoritativeness, and trustworthiness—those invested in these machines are well-positioned to lead in a rapidly evolving industry.

Furthermore, the architectural benefits of metal roofing cannot be overstated. Metal tiles formed through these machines are not only durable and long-lasting but also aesthetically pleasing. They provide superior protection against the elements, displaying excellent resistance to wind, hail, and fire. As sustainability becomes increasingly important in construction, metal roofing stands out for its energy efficiency and recyclability, attributes that are gaining favor among environmentally conscious consumers and builders. Investing in a metal tile roof roll forming machine is a strategic decision that promises a high return on investment. The initial costs are balanced by the machine's long lifespan, low maintenance requirements, and the high-value output it facilitates. Moreover, the customizable nature of metal roofing tiles means that businesses can continuously adapt to market trends, ensuring their offerings remain relevant and appealing over time. In ensuring the best outcomes from these machines, choosing the right supplier is crucial. Prospective buyers should look for suppliers with established reputations, who offer rigorous quality controls and comprehensive after-sales support. This diligence will ensure the machine operates at peak efficiency, upholding its promise of precision and performance. In conclusion, metal tile roof roll forming machines are unrivaled assets in the metal roofing industry. These machines marry expertise with practicality, providing solutions that meet both traditional and modern roofing demands. By prioritizing quality, customer support, and innovation, manufacturers and suppliers affirm trustworthiness and authoritative expertise, essential qualities for success in a competitive marketplace. Through these dimensions—experience, expertise, authoritativeness, and trustworthiness—those invested in these machines are well-positioned to lead in a rapidly evolving industry.

Latest news

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

Related Products