Mar . 05, 2025 04:19

Back to list

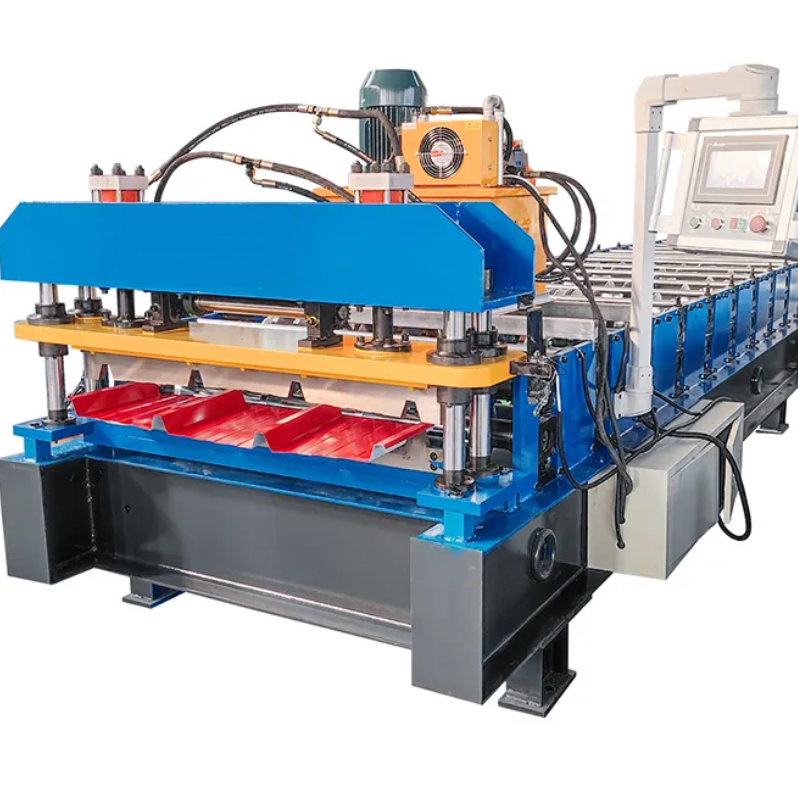

rib roof panel roll forming machine

Rib roof panel roll forming machines have revolutionized the construction industry, offering efficiency, precision, and adaptability to a wide array of roofing projects. These machines are designed to craft ribbed metal sheets that not only enhance the aesthetic appeal of a structure but also contribute significantly to its durability and weather resistance. As an expert in the field of construction machinery, I will delve into the multifaceted benefits and technical aspects that these innovative machines bring to the table.

Trustworthiness is another critical factor that endears these machines to users. The consistency and reliability of the output produced by rib roof panel roll forming machines are unmatched. Clients and contractors can depend on the machines to produce panels that meet strict tolerances and specifications. Furthermore, those looking to invest in such machinery can rest assured that reputable manufacturers offer comprehensive warranties and customer support services. This includes preventive maintenance programs and readily available replacement parts, ensuring that any downtime is minimized and productivity remains uninterrupted. From a technical standpoint, the operation of a rib roof panel roll forming machine involves feeding a coil of metal sheet through a series of rollers that progressively shape it into the desired ribbed profile. The machines are equipped with programmable logic controllers (PLCs) that allow operators to input precise specifications for each panel, including width, gauge, and rib spacing. This level of automated precision reduces the likelihood of human error and guarantees uniformity across all panels produced. In conclusion, rib roof panel roll forming machines represent a fusion of engineering excellence and practical utility, underscoring their essential role in modern construction. Their ability to enhance efficiency, coupled with their reliability and adaptability, makes them a worthwhile investment for any construction business. By adhering to best practices in operation and maintenance, users can fully leverage the capabilities of these machines, delivering projects that meet high standards of quality and client satisfaction.

Trustworthiness is another critical factor that endears these machines to users. The consistency and reliability of the output produced by rib roof panel roll forming machines are unmatched. Clients and contractors can depend on the machines to produce panels that meet strict tolerances and specifications. Furthermore, those looking to invest in such machinery can rest assured that reputable manufacturers offer comprehensive warranties and customer support services. This includes preventive maintenance programs and readily available replacement parts, ensuring that any downtime is minimized and productivity remains uninterrupted. From a technical standpoint, the operation of a rib roof panel roll forming machine involves feeding a coil of metal sheet through a series of rollers that progressively shape it into the desired ribbed profile. The machines are equipped with programmable logic controllers (PLCs) that allow operators to input precise specifications for each panel, including width, gauge, and rib spacing. This level of automated precision reduces the likelihood of human error and guarantees uniformity across all panels produced. In conclusion, rib roof panel roll forming machines represent a fusion of engineering excellence and practical utility, underscoring their essential role in modern construction. Their ability to enhance efficiency, coupled with their reliability and adaptability, makes them a worthwhile investment for any construction business. By adhering to best practices in operation and maintenance, users can fully leverage the capabilities of these machines, delivering projects that meet high standards of quality and client satisfaction.

Latest news

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

Related Products