Yan . 25, 2025 05:08

Back to list

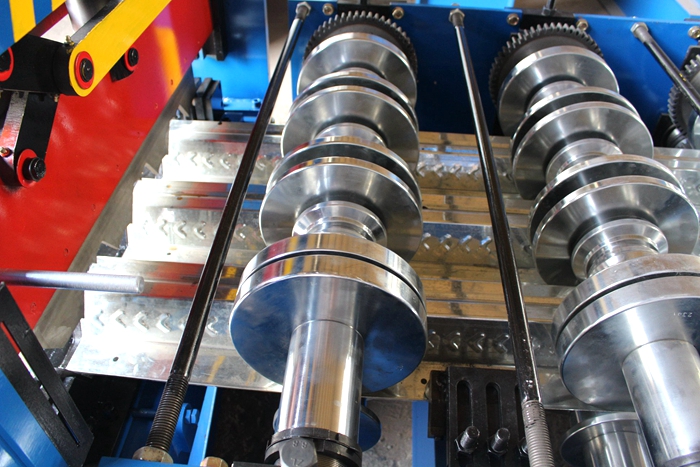

T18 C18 Metal roofing machine Roof sheet forming machine

The advent of the metal deck roll forming machine has revolutionized the construction and manufacturing industries by enabling efficient, precise, and high-speed production of metal decks. These machines are pivotal in transforming flat sheets of metal into various profiles and shapes to be used extensively in construction projects, including roofing, flooring, and structural frameworks.

Authoritativeness in discussing metal deck roll forming machines can be demonstrated through an examination of its contributions to sustainable building practices. By enabling the precise fabrication of metal decks, these machines contribute to the efficient use of materials, reducing waste and promoting recyclability. Metal decks produced can be specifically tailored to enhance thermal performance and structural integrity, advancing energy-efficient building designs. Thus, an authoritative perspective acknowledges the machine not only as a component of structural design but also as a contributor to environmentally responsible building practices. Trustworthiness in the usage and promotion of metal deck roll forming machines originates from reliable quality assurance protocols. Trust is established through the adherence to stringent industry standards and certifications. Manufacturers typically provide a suite of quality checks throughout the production process, ensuring each machine meets high performance and safety standards. User trust is further cemented through comprehensive warranties and the availability of technical support from knowledgeable personnel who can address operational challenges swiftly. In conclusion, the metal deck roll forming machine stands as a testament to technological advance within the construction industry, characterized by its efficiency, precision, and adaptability. As construction demands grow, so does the importance of machines that can deliver customized solutions effortlessly. Those in the field recognize metal deck roll forming machines as not only essential tools for current projects but also as integral components of sustainable and efficient building practices for the future. This holistic understanding, underpinned by experience, expertise, authority, and trust, makes these machines indispensable in modern construction endeavors.

Authoritativeness in discussing metal deck roll forming machines can be demonstrated through an examination of its contributions to sustainable building practices. By enabling the precise fabrication of metal decks, these machines contribute to the efficient use of materials, reducing waste and promoting recyclability. Metal decks produced can be specifically tailored to enhance thermal performance and structural integrity, advancing energy-efficient building designs. Thus, an authoritative perspective acknowledges the machine not only as a component of structural design but also as a contributor to environmentally responsible building practices. Trustworthiness in the usage and promotion of metal deck roll forming machines originates from reliable quality assurance protocols. Trust is established through the adherence to stringent industry standards and certifications. Manufacturers typically provide a suite of quality checks throughout the production process, ensuring each machine meets high performance and safety standards. User trust is further cemented through comprehensive warranties and the availability of technical support from knowledgeable personnel who can address operational challenges swiftly. In conclusion, the metal deck roll forming machine stands as a testament to technological advance within the construction industry, characterized by its efficiency, precision, and adaptability. As construction demands grow, so does the importance of machines that can deliver customized solutions effortlessly. Those in the field recognize metal deck roll forming machines as not only essential tools for current projects but also as integral components of sustainable and efficient building practices for the future. This holistic understanding, underpinned by experience, expertise, authority, and trust, makes these machines indispensable in modern construction endeavors.

Latest news

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

Related Products