Xəbərlər

-

Embossing is a technique commonly used in the metalworking industry to create designs, patterns or textures on metal surfaces.Daha çox oxu

Embossing is a technique commonly used in the metalworking industry to create designs, patterns or textures on metal surfaces.Daha çox oxu -

Metal embossing is a unique and creative way to add texture and design to metal plates, and it can be done with the help of a metal embossing machine.Daha çox oxu

Metal embossing is a unique and creative way to add texture and design to metal plates, and it can be done with the help of a metal embossing machine.Daha çox oxu -

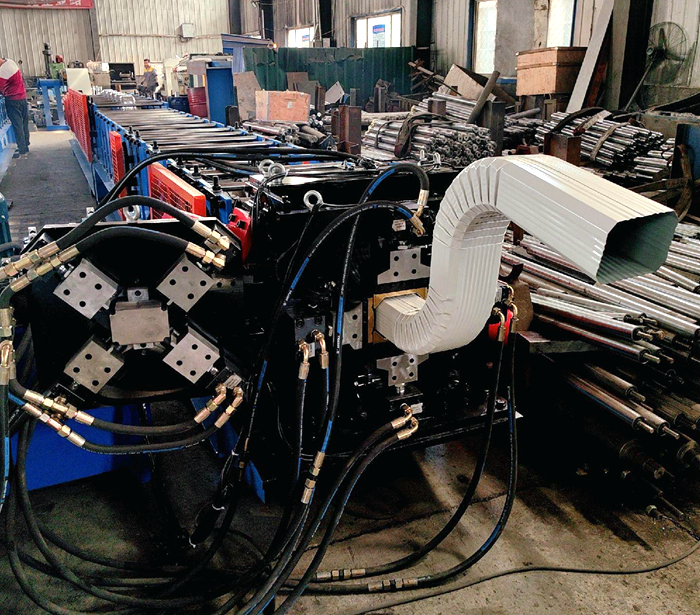

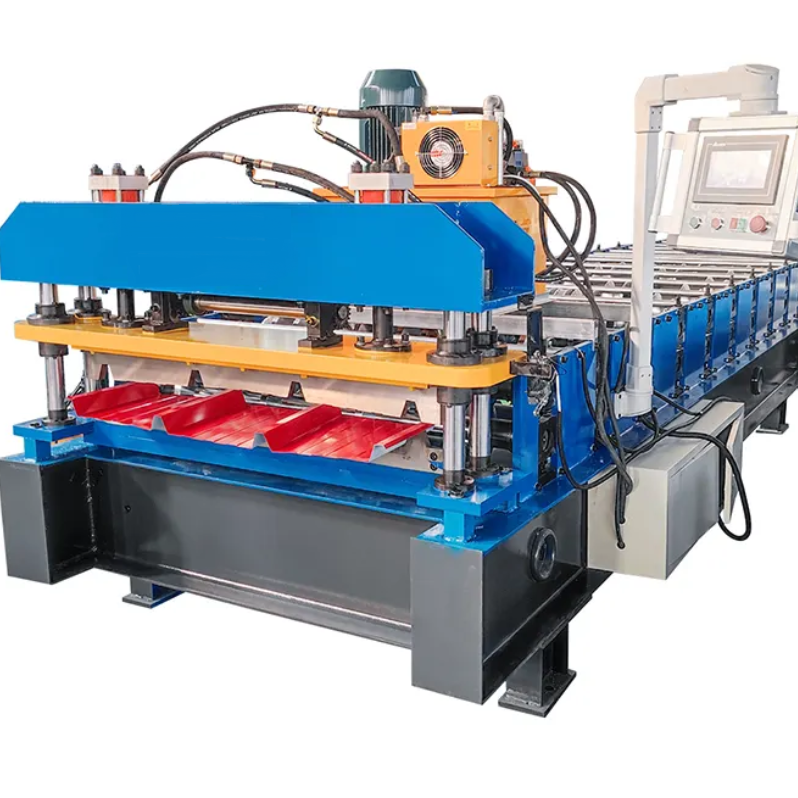

Nowadays, there are many gutter machine manufacturers on the gutter forming machine for saleDaha çox oxu

Nowadays, there are many gutter machine manufacturers on the gutter forming machine for saleDaha çox oxu -

A roof is typically installed once the majority of the construction work is finished. Even though it is towards the last few items in the chronology, they are very essential. Roofing Sheets increase the appeal of the home as well as safety. Proper thought must be put into its buying efforts. They are not just a sheet on top of your home. A roofing system is more than the limited scope of its definition. Choosing a suitable roofing sheet would provide both form and function benefits to your home.Daha çox oxu

A roof is typically installed once the majority of the construction work is finished. Even though it is towards the last few items in the chronology, they are very essential. Roofing Sheets increase the appeal of the home as well as safety. Proper thought must be put into its buying efforts. They are not just a sheet on top of your home. A roofing system is more than the limited scope of its definition. Choosing a suitable roofing sheet would provide both form and function benefits to your home.Daha çox oxu -

We get asked from time to time, if corrugated steel roof sheets need to be treated for corrosion then why are they used in the first place. The simple answer is because they are the best material available right now for industrial large scale roofing. Many commercial construction businesses choose corrugated roofing because its advantages far outweigh the disadvantages. Traditional roofing materials such as asphalt or roof tiles are simply not suitable for most commercial premises. Corrugated steel roofing is the perfect choice for businesses who want to move water and moisture off a roof quickly and maintain control over internal temperatures.Daha çox oxu

We get asked from time to time, if corrugated steel roof sheets need to be treated for corrosion then why are they used in the first place. The simple answer is because they are the best material available right now for industrial large scale roofing. Many commercial construction businesses choose corrugated roofing because its advantages far outweigh the disadvantages. Traditional roofing materials such as asphalt or roof tiles are simply not suitable for most commercial premises. Corrugated steel roofing is the perfect choice for businesses who want to move water and moisture off a roof quickly and maintain control over internal temperatures.Daha çox oxu -

Metal roofing offers a range of benefits that make it an increasingly popular choice for homeowners. Here are some key advantages of opting for metal roofingDaha çox oxu

Metal roofing offers a range of benefits that make it an increasingly popular choice for homeowners. Here are some key advantages of opting for metal roofingDaha çox oxu -

If you’ve spent hours grafting away making your roof perfect only to discover condensation starting to creep in, you’ll probably feel quite annoyed. All the hours of hard work up a ladder – and for what?Exposed to the elements day in and out, condensation can start to build up on your roofing sheets, leading to damage, rust and corrosion. But it doesn’t have to be that way. With a little care and attention, you can ensure that your roof lasts for years to come.If you’re looking to restore your metal roofing sheets to their former glory, you’re in the right place.Read on for tips and tricks of the trade or visit our Burton Roofing blog, which is packed with helpful resources to make your life that little bit easier.Daha çox oxu

If you’ve spent hours grafting away making your roof perfect only to discover condensation starting to creep in, you’ll probably feel quite annoyed. All the hours of hard work up a ladder – and for what?Exposed to the elements day in and out, condensation can start to build up on your roofing sheets, leading to damage, rust and corrosion. But it doesn’t have to be that way. With a little care and attention, you can ensure that your roof lasts for years to come.If you’re looking to restore your metal roofing sheets to their former glory, you’re in the right place.Read on for tips and tricks of the trade or visit our Burton Roofing blog, which is packed with helpful resources to make your life that little bit easier.Daha çox oxu -

It is very difficult for metal roof sheets in Doncaster already fitter to a roof to be retro fitted with insulation. Unless you can get insulation in contact with all of the underside of the metal roof, you will get condensation. If you are using insulation sheets such as polystyrene, you are likely to have some run-off.One solution is to use a RockWool type insulation which is pushed up into contact with the underside of the metal sheets. This stops airflow and thus, stops condensation. Your best option is to buy a sheet which has been specifically manufactured as a composite insulated roofing sheet.Daha çox oxu

It is very difficult for metal roof sheets in Doncaster already fitter to a roof to be retro fitted with insulation. Unless you can get insulation in contact with all of the underside of the metal roof, you will get condensation. If you are using insulation sheets such as polystyrene, you are likely to have some run-off.One solution is to use a RockWool type insulation which is pushed up into contact with the underside of the metal sheets. This stops airflow and thus, stops condensation. Your best option is to buy a sheet which has been specifically manufactured as a composite insulated roofing sheet.Daha çox oxu -

NOW THAT THE construction industry has returned to work, for many it will be time to think about choosing a metal roof for a building project.Metal roofs can be a good investment because they are lightweight and durable. They are also very quick to install. Steel roofing sheets are extremely weatherproof, able to withstand high winds, rain, snow and even fire, so are an attractive option. An added bonus is that they are unaffected by fungus, moss, or mildew – and resistant to damage from wild animals and pests.Daha çox oxu

NOW THAT THE construction industry has returned to work, for many it will be time to think about choosing a metal roof for a building project.Metal roofs can be a good investment because they are lightweight and durable. They are also very quick to install. Steel roofing sheets are extremely weatherproof, able to withstand high winds, rain, snow and even fire, so are an attractive option. An added bonus is that they are unaffected by fungus, moss, or mildew – and resistant to damage from wild animals and pests.Daha çox oxu -

and excellent service set us apart, as reliable, cost effective suppliers.We supply a range of high quality roofing sheets, metal roofing and roof fixings, serving metal roofing sheets with industrial, agricultural and commercial roofing, cladding and building products.We offer our products in a range of materials and finishes; just let us know your requirements and in return we'll offer the perfect solution.Daha çox oxu

and excellent service set us apart, as reliable, cost effective suppliers.We supply a range of high quality roofing sheets, metal roofing and roof fixings, serving metal roofing sheets with industrial, agricultural and commercial roofing, cladding and building products.We offer our products in a range of materials and finishes; just let us know your requirements and in return we'll offer the perfect solution.Daha çox oxu -

We began to see a lot of roof items that required roof sheet replacement and metal cladding sheet replacement due to damage, corrosion, dents, redundant vents etc. So we decided to offer this service so our clients could keep all the roof work items under one house. It has proven to be a very convenient service for our clients especially for time keeping when carrying out metal roof coating systems.Daha çox oxu

We began to see a lot of roof items that required roof sheet replacement and metal cladding sheet replacement due to damage, corrosion, dents, redundant vents etc. So we decided to offer this service so our clients could keep all the roof work items under one house. It has proven to be a very convenient service for our clients especially for time keeping when carrying out metal roof coating systems.Daha çox oxu -

Whether you're buying a home with one or thinking of installing, here's what to know. Whether you're putting a roof on a new home, or your existing roof requires a total makeover, there are many materials available. But no matter what roof style you have, metal roofs can be an attractive option because of their longevity, minimal maintenance and energy efficiency. Material choices include steel (galvanized, galvalume or weathering), aluminum, copper, zinc and tin. Product types are vertical seam, pre-formed panels and granular coated panels. Style choices allow you to have the look of shingles, slate, tile, shakes or vertical panels. Make sure your metal roofing product is tested, labeled and listed with a testing organization such as UL, FM Approvals or Intertek to meet rigorous wind, fire and impact resistance rating requirements. Please also remember that installation can vary from geographic location, manufacturer guidelines and as a result of local building code requirements.Daha çox oxu

Whether you're buying a home with one or thinking of installing, here's what to know. Whether you're putting a roof on a new home, or your existing roof requires a total makeover, there are many materials available. But no matter what roof style you have, metal roofs can be an attractive option because of their longevity, minimal maintenance and energy efficiency. Material choices include steel (galvanized, galvalume or weathering), aluminum, copper, zinc and tin. Product types are vertical seam, pre-formed panels and granular coated panels. Style choices allow you to have the look of shingles, slate, tile, shakes or vertical panels. Make sure your metal roofing product is tested, labeled and listed with a testing organization such as UL, FM Approvals or Intertek to meet rigorous wind, fire and impact resistance rating requirements. Please also remember that installation can vary from geographic location, manufacturer guidelines and as a result of local building code requirements.Daha çox oxu