Xəbərlər

-

In the realm of roofing sheet-making machinery, choosing the right supplier is crucial toDaha çox oxu

In the realm of roofing sheet-making machinery, choosing the right supplier is crucial toDaha çox oxu -

In the realm of roofing sheet-making machinery, choosing the right supplier is crucial toDaha çox oxu

In the realm of roofing sheet-making machinery, choosing the right supplier is crucial toDaha çox oxu -

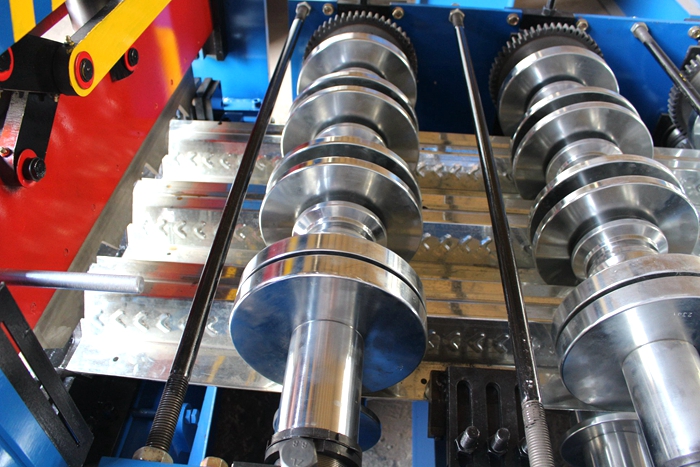

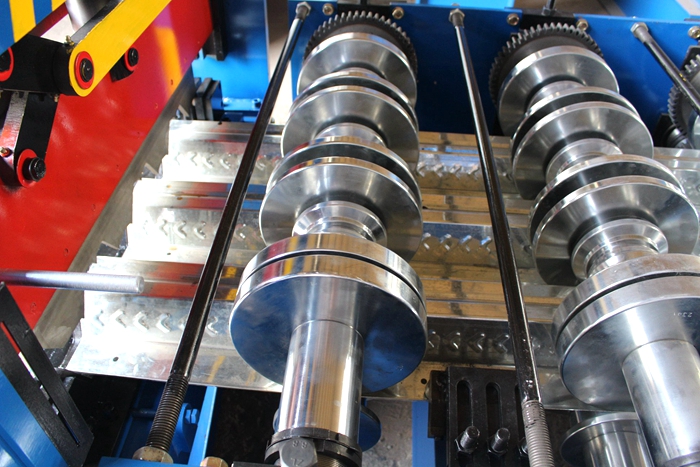

Roll forming is the process in which sheet metal is sent through a series of rollers which flatten, bend, and shape the sheet metal into the desired profile. Once the required shape has been achieved, the metal can be cleaned, anodized, detailed, and cut into desired lengths.Daha çox oxu

Roll forming is the process in which sheet metal is sent through a series of rollers which flatten, bend, and shape the sheet metal into the desired profile. Once the required shape has been achieved, the metal can be cleaned, anodized, detailed, and cut into desired lengths.Daha çox oxu -

Whether you notice it or not, products made using the process of metal rollforming are everywhere. Items could include something as visible as metal roofing or garage doors, or products working behind the scenes, like pipes, window frames, and countless others.Daha çox oxu

Whether you notice it or not, products made using the process of metal rollforming are everywhere. Items could include something as visible as metal roofing or garage doors, or products working behind the scenes, like pipes, window frames, and countless others.Daha çox oxu -

Rolling is a forming process which reduces the cross-sectional area of the incoming metal stock or produces a new cross-section of the material at the exit while improving its mechanical properties through the use of rotating rolls.Daha çox oxu

Rolling is a forming process which reduces the cross-sectional area of the incoming metal stock or produces a new cross-section of the material at the exit while improving its mechanical properties through the use of rotating rolls.Daha çox oxu -

Roll forming machinery is a boon for both the quality and efficiency of metal fabrication. It allows for repeatable consistency within a product run, as well as versatility in design configurations and materials for metal parts. With wide-ranging applications from appliances and furniture to telecommunications and supports or frames for construction, this equipment produces large volumes of formed metal parts quickly, accurately, and affordably through consecutive bending stages.Daha çox oxu

Roll forming machinery is a boon for both the quality and efficiency of metal fabrication. It allows for repeatable consistency within a product run, as well as versatility in design configurations and materials for metal parts. With wide-ranging applications from appliances and furniture to telecommunications and supports or frames for construction, this equipment produces large volumes of formed metal parts quickly, accurately, and affordably through consecutive bending stages.Daha çox oxu -

Roll form machines are designed to make sheet metal into straight formed shapes. The roll forming process takes a continuous flat sheet of metal and power feeds it through a successive series of Hardened Steel Rollers, which station by station shape the metal into a finished shape as it passes through them. This method allows for rapid shaping of sheet metal into many shapes.Daha çox oxu

Roll form machines are designed to make sheet metal into straight formed shapes. The roll forming process takes a continuous flat sheet of metal and power feeds it through a successive series of Hardened Steel Rollers, which station by station shape the metal into a finished shape as it passes through them. This method allows for rapid shaping of sheet metal into many shapes.Daha çox oxu -

Have you ever wondered how the fender on your car is manufactured? It is prepared using a technique called roll forming. Roll forming is the process of bending metal into an engineered shape by passing it through a set of consecutive rolls and stands. Each stand gives the metal an incremental bend until the desired shape is achieved.Daha çox oxu

Have you ever wondered how the fender on your car is manufactured? It is prepared using a technique called roll forming. Roll forming is the process of bending metal into an engineered shape by passing it through a set of consecutive rolls and stands. Each stand gives the metal an incremental bend until the desired shape is achieved.Daha çox oxu -

If sheet metal fabrication and aluminum extruding got together and had a baby, you’d get roll forming. Roll forming is like sheet metal fabrication where thin flat sheets of metal are bent into a 3D shape, but in contrast, these bends are formed gradually and continuously so a constant 2D cross-sectional shape comes out the other end like an extrusion. Long strips or coils of flat metal are fed into one end of a roll forming line where it passes through a series of rolling dies and comes out the end in a totally new shape.Daha çox oxu

If sheet metal fabrication and aluminum extruding got together and had a baby, you’d get roll forming. Roll forming is like sheet metal fabrication where thin flat sheets of metal are bent into a 3D shape, but in contrast, these bends are formed gradually and continuously so a constant 2D cross-sectional shape comes out the other end like an extrusion. Long strips or coils of flat metal are fed into one end of a roll forming line where it passes through a series of rolling dies and comes out the end in a totally new shape.Daha çox oxu -

we detailed the advantages of press braking, comparing it to roll forming as a metal fabrication bending process. Although they have little in common, other than the process category, both are important and have many uses. More than anything, choosing one over the other depends mainly on the end product undergoing fabrication. This week, we’ll take a look at closer look at roll forming specifically.Daha çox oxu

we detailed the advantages of press braking, comparing it to roll forming as a metal fabrication bending process. Although they have little in common, other than the process category, both are important and have many uses. More than anything, choosing one over the other depends mainly on the end product undergoing fabrication. This week, we’ll take a look at closer look at roll forming specifically.Daha çox oxu -

Roll forming is superior to other metal forming processes and has advantages over aluminum extrusions, for many reasons.Daha çox oxu

Roll forming is superior to other metal forming processes and has advantages over aluminum extrusions, for many reasons.Daha çox oxu -

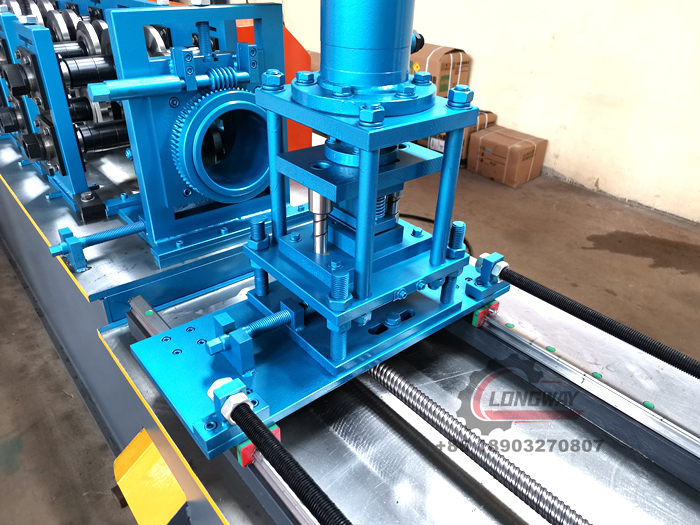

A roll former may appear to be a tremendously complex machine, with its wide array of stations and high speeds. It’s worth learning about how it works because it can perform a unique function and create identical end products consistently that meet the strictest of specifications.Daha çox oxu

A roll former may appear to be a tremendously complex machine, with its wide array of stations and high speeds. It’s worth learning about how it works because it can perform a unique function and create identical end products consistently that meet the strictest of specifications.Daha çox oxu