Top Steel Manufacturers Specializing in Roll Forming Technology and Solutions

Understanding Roll Forming Steel An Insight into Leading Manufacturers

Roll forming is a highly efficient manufacturing process used to create elongated parts with uniform cross-sections, often made from metal sheets, including steel. The functionality of this technique plays a vital role in various industries, including automotive, construction, and appliances. With a demand for lightweight yet sturdy materials, many businesses turn to roll forming, and understanding the landscape of roll forming steel manufacturers is crucial for companies seeking reliable partners in production.

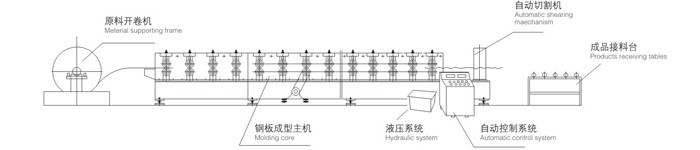

The Roll Forming Process

The roll forming process involves feeding a flat strip of metal, typically steel, through a series of rollers that shape it into a specified cross-section. This method allows for continuous production and can be adapted to different materials and geometries, making it versatile for various applications. The steel used can range from mild to high-strength variants, depending on the end-use requirements, such as load-bearing capacity, flexibility, or corrosion resistance.

One of the primary advantages of roll forming is its efficiency. Once the tooling is made, the process can produce large volumes of parts with minimal waste, thereby favorably impacting production costs. Additionally, the smooth finish achieved through roll forming often eliminates the need for secondary processing, further enhancing cost-efficiency.

Key Manufacturers in the Industry

The roll forming steel market features a range of manufacturers, from large corporations to specialized firms. Leading companies stand out due to their technological expertise, quality assurance processes, and the diversity of their product offerings.

1. Worthington Industries A pioneer in the roll forming sector, Worthington Industries is well-known for its innovation and quality. With facilities across North America, they offer a variety of roll-formed steel products that cater to different industries, including construction and automotive. Their commitment to sustainability and advanced manufacturing techniques positions them as a choice leader in the roll forming industry.

roll forming steel manufacturers

2. SteelPartners Holdings This company specializes in several manufacturing processes, including roll forming. They leverage extensive industry experience to deliver high-quality roll-formed steel products, emphasizing custom solutions tailored to client specifications. SteelPartners is recognized for its adaptability and responsiveness to changing market demands.

3. Nucor Corporation Nucor is one of the largest steel producers in the United States and has made significant investments in roll forming technology. Their operations emphasize eco-friendly production methods and high-grade steel products. Nucor's roll forming division provides solutions for various sectors, showcasing its ability to meet diverse consumer needs.

4. Cleveland Steel Tool Company This manufacturer focuses on precision and innovation in roll-forming processes. Known for their custom tooling and product designs, they work closely with clients to provide tailored solutions. Their experience in the industry has allowed them to develop specialized products that meet the rigorous demands of today’s manufacturing landscape.

Quality and Innovation

While the competition among roll forming steel manufacturers is fierce, quality control and innovation provide them with a competitive edge. Many manufacturers invest significantly in research and development to innovate their processes and materials. Advanced automation, real-time monitoring, and integrated design software are becoming standard practices, ensuring that customers receive high-quality components consistently.

Conclusion

The roll forming steel industry is pivotal in modern manufacturing, driven by the need for efficient production methods and high-quality materials. Leading manufacturers play an essential role in shaping this industry through their commitment to innovation and quality assurance. As industries continue to evolve, roll forming steel manufacturers are likely to adapt and expand their capabilities to meet new challenges and opportunities, solidifying their importance in the manufacturing ecosystem. For businesses seeking reliable partners in steel production, understanding these dynamics and exploring the offerings of top manufacturers can lead to successful collaborations and sustainable growth.

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025