purlin rollforming machine

Understanding Purlin Roll Forming Machines

In the world of construction and manufacturing, efficiency and precision are critical. One of the key components in achieving these goals is the purlin roll forming machine. This innovative equipment plays a vital role in the production of purlins, which are essential structural elements in various building projects. This article delves into the workings of purlin roll forming machines, their importance, and the advantages they offer to the construction industry.

What is a Purlin?

Purlins are horizontal structural members used to support roof and wall cladding in buildings. They are typically made from steel and provide strength and stability to the structures they support. Purlins come in different shapes and sizes, including C, Z, and U profiles, depending on the architectural and engineering requirements of a project. The use of purlins can significantly enhance a structure's load-bearing capabilities, making them a crucial part of any construction project.

How Does a Purlin Roll Forming Machine Work?

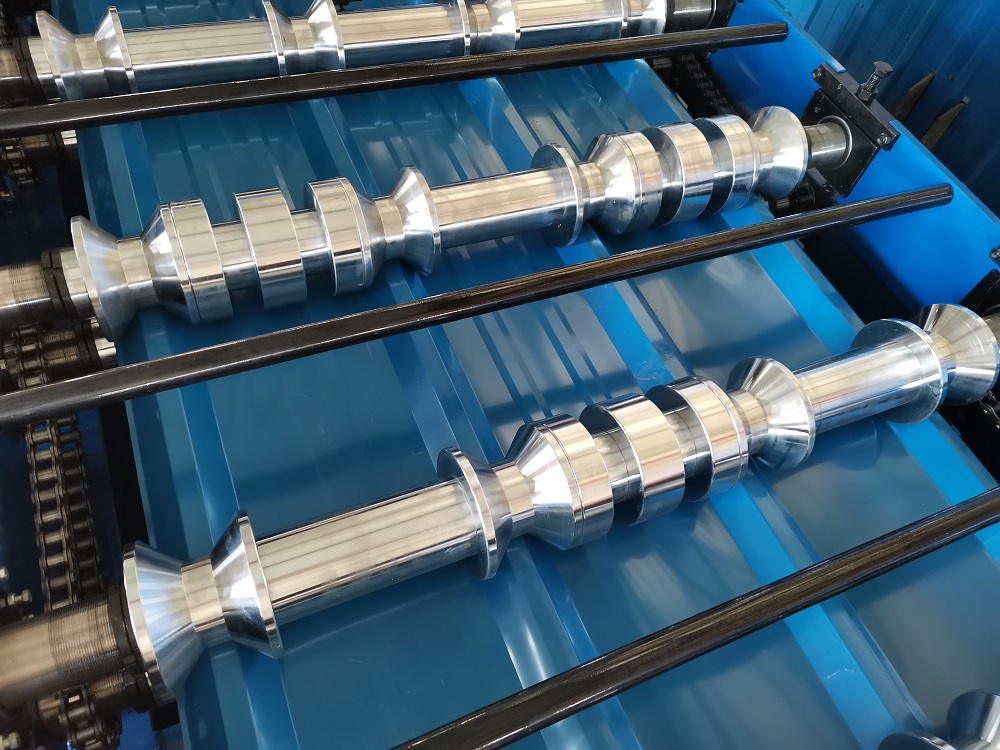

Purlin roll forming machines are specialized pieces of equipment designed to produce purlins efficiently and accurately. The process begins with the feeding of flat steel sheets into the machine. These sheets are then passed through a series of rollers that progressively shape them into the desired profile.

The roll forming process is continuous, which means that as the flat sheet moves through the machine, it is gradually transformed into a finished purlin without the need for cutting or welding. This not only minimizes waste but also increases production speed. After the roll forming process, additional operations such as punching holes for bolts or trimming can be performed, depending on the specific requirements of the purlin being produced.

Advantages of Purlin Roll Forming Machines

purlin rollforming machine

1. High Efficiency One of the primary advantages of using a purlin roll forming machine is the speed at which purlins can be produced. Conventional methods of purlin fabrication can be time-consuming, but roll forming machines streamline the process, allowing for large quantities to be produced in a shorter time frame.

2. Cost-Effective By minimizing material waste and labor costs, purlin roll forming machines can significantly reduce the overall expenses associated with purlin production. This cost-effectiveness makes them an attractive option for manufacturers and builders alike.

3. Precision and Quality The automated nature of roll forming machines ensures that each purlin is produced with high precision. This consistency in quality is essential for maintaining structural integrity in construction projects.

4. Customization Purlin roll forming machines can be adjusted to produce various purlin profiles, allowing manufacturers to cater to specific project needs. This flexibility helps in accommodating different designs and engineering specifications.

5. Durability The materials used in purlin production are typically steel, which is known for its strength and longevity. Purlins produced by roll forming machines are capable of withstanding harsh environmental conditions, making them suitable for both residential and commercial applications.

Conclusion

Purlin roll forming machines represent a significant advancement in the construction and manufacturing industries. By enhancing efficiency, reducing costs, and ensuring high-quality production, these machines are instrumental in the creation of durable structural elements that support a variety of building projects. As technology continues to evolve, the role of purlin roll forming machines will undoubtedly grow, paving the way for even more innovative solutions in construction.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025