Custom Design Metal Plate Embosser for Personalized Embossing Projects

The Art and Utility of Metal Plate Embossers

Metal plate embossers have emerged as an essential tool in various industries, combining artistry with functionality. This process involves the creation of raised designs or texts on metal surfaces, primarily using a combination of heat and pressure. The outcome is not only visually striking but also has practical applications in security, branding, and decoration.

Understanding the Embossing Process

Embossing is a technique that relies on the physical alteration of materials, creating a three-dimensional effect. In the context of metal plates, it typically involves either a manual or mechanical press that forces a design into the metal. The metal is usually softened using heat, making it more receptive to the pressure exerted by the embossing die. This technique can be applied to a variety of metals, including aluminum, brass, and steel, allowing for a broad range of products and applications.

Applications of Metal Plate Embossers

1. Branding Businesses have found metal embossing to be a highly effective branding tool. Companies often emboss their logos, product names, or other identifiers onto metal surfaces to enhance their brand’s visibility and recognition. This can be seen in various products, such as luxury goods, promotional items, and packaging materials. An embossed logo can signify quality and precision, attributes that many brands strive to communicate to their consumers.

2. Identification and Security In security applications, metal plate embossers play a crucial role. For example, identification badges or access cards often use embossing to create raised text or patterns. This not only aids in instantly recognizing the cardholder but also provides a level of tampering resistance, making counterfeiting more difficult. Similarly, various official documents and certificates often utilize embossed seals as a measure of authenticity.

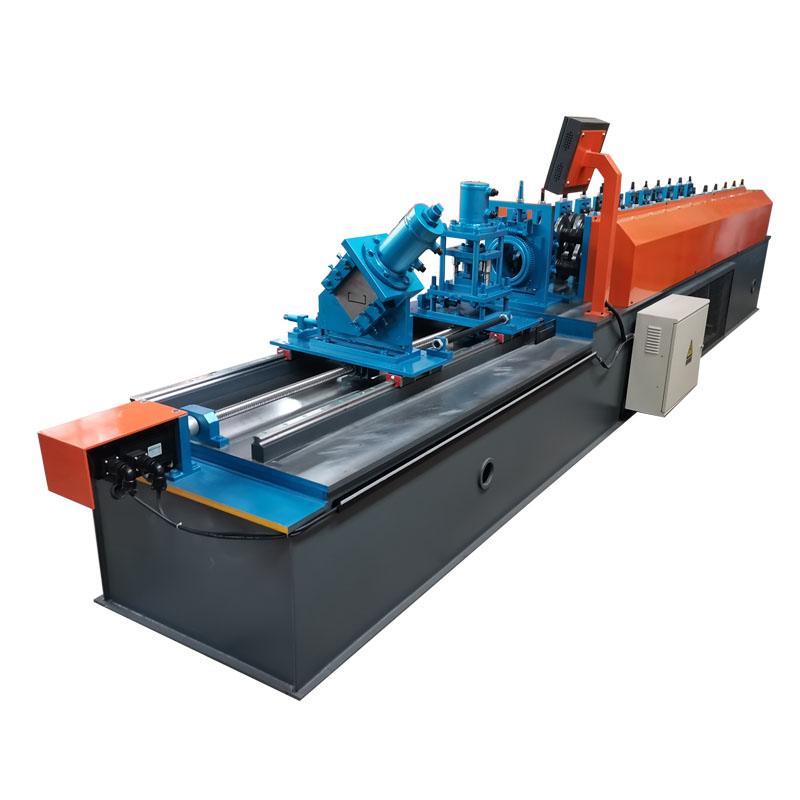

metal plate embosser

3. Decorative Uses The decorative potential of metal plate embossers cannot be overlooked. Artists and craftsmen often use this technique to create stunning pieces of art, custom signs, and even furniture details. Embossed metal art can range from intricate patterns to bold logos and designs, allowing for tremendous creativity. In architecture, embossed metal is sometimes used in facade treatments or interior design, contributing to a unique aesthetic appeal.

4. Functional Products Metal plates that are embossed can also serve functional purposes beyond decoration. For instance, kitchenware items like trivets or serving trays can be embossed to improve grip and prevent slipping. Additionally, embossed plates are utilized in tools or equipment where the embossed surface provides texture or enhances functionality.

Choosing the Right Embosser

When selecting a metal plate embosser, several factors need to be considered to ensure the desired outcome

- Type of Metal Different metals respond differently to embossing techniques. Aluminum, for instance, is favored for its lightweight nature and malleability. - Design Complexity The complexity of the desired design will dictate the type of embosser required. For intricate designs, a higher-end mechanical or hydraulic press might be necessary. - Volume of Production For large-scale production, automated embossers may be more efficient, while for smaller custom jobs, manual embossers could suffice. - Heat Source For optimal results, the choice of heating method—whether electric, gas, or induction—can influence the quality of the embossed pattern.

Conclusion

In summary, metal plate embossers beautifully fuse creativity with practicality, producing results that serve both aesthetic and functional purposes. From branding and security to artistry and utility, these devices find relevance across numerous fields. As technology advances, we can only expect to see even more innovative applications emerge, highlighting the enduring appeal and significance of embossed metals in our everyday lives. Whether for personal projects or commercial use, metal plate embossers continue to represent a convergence of art and function, making them invaluable tools in contemporary craftsmanship.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025