industrial roll forming machine

Industrial Roll Forming Machines An Overview

Industrial roll forming machines are essential tools in the manufacturing process, particularly for industries that require long, continuous products with consistent cross-sectional shapes. These machines are widely used in producing metal parts for construction, automotive, and various other applications. The roll forming process involves feeding a metal strip through a series of rollers, which progressively shape the material into the desired profile. This article explores the mechanics, advantages, and applications of industrial roll forming machines.

The operational principle of roll forming is straightforward yet highly efficient. It begins with a flat metal sheet or roll, usually made from steel or aluminum, which is unwound and fed into the machine. As the metal strip passes through a sequence of rollers, each positioned at a specific angle, it undergoes a gradual deformation. This method allows for intricate designs and precise dimensions, producing high-quality components. The final product is typically a long, continuous piece, which can be cut to size according to requirements.

One of the key advantages of roll forming is its ability to create complex shapes with minimal waste. Since the process is continuous, it reduces scrap material often associated with traditional methods like stamping or punching. Moreover, roll forming can accommodate various materials and thicknesses, enhancing its versatility. The machine's speed is another significant benefit; it can produce components at a much faster rate than other forming methods, leading to increased productivity and reduced lead times.

industrial roll forming machine

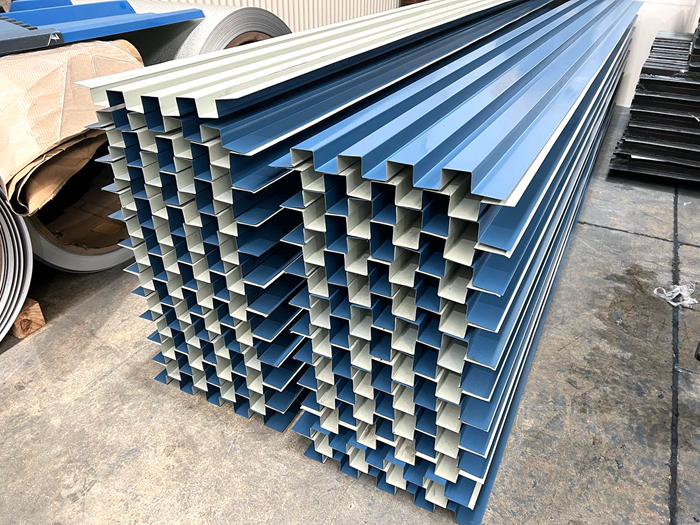

The applications of industrial roll forming machines are vast. In the construction sector, they are commonly used to create components such as roofing sheets, wall panels, and structural sections. These products are not only lightweight but also provide excellent strength, making them ideal for high-rise buildings and industrial facilities. Additionally, in the automotive industry, roll forming is employed to manufacture parts such as chassis, brackets, and support systems. The precision in the roll forming process ensures that these components meet stringent safety and regulatory standards.

Furthermore, roll forming technology has evolved over the years. Modern machines often include automation features, such as programmable logic controllers (PLCs) and computer numerical control (CNC), allowing for more accurate control over the forming process. This technological advancement enhances the machine's ability to produce consistent and repeatable products while minimizing human error. Additionally, integrating advanced sensors and monitoring systems can optimize the manufacturing workflow, paving the way for smart manufacturing practices.

In conclusion, industrial roll forming machines play a vital role in modern manufacturing, providing efficiency, precision, and versatility. Their ability to create intricate shapes from metal strips makes them indispensable in various industries. As technology continues to advance, roll forming machines are expected to become even more efficient and user-friendly, driving innovation and productivity in manufacturing processes around the globe. The demand for high-quality, cost-effective products will likely increase, ensuring that the roll forming process remains a cornerstone of industrial production for years to come.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025