high precision slitting line machine

High Precision Slitting Line Machines Advancing Metal Processing

In the world of metal processing, precision and efficiency are paramount. This is where high precision slitting line machines come into play, offering advanced solutions for cutting metal sheets into narrower rolls with exceptional accuracy. These machines are designed not only for high productivity but also for delivering superior quality and minimizing material waste, making them an invaluable asset in industries such as automotive, aerospace, and electronics.

Understanding Slitting Processes

Slitting is a process used to cut large rolls of metal (often referred to as coils) into narrower strips or sheets that can be further processed or transported. During this operation, the material can be subjected to high-speed blades that cut through the metal, aligning with the precise specifications required by downstream applications. The primary objective is to maintain tight tolerances on width and maintain the integrity of the material. High precision slitting line machines utilize state-of-the-art technology to achieve these goals consistently.

Key Features of High Precision Slitting Lines

1. Advanced Technology Modern slitting machines are equipped with the latest control and automation systems. Features such as programmable logic controllers (PLCs) and touch screen interfaces allow operators to set parameters accurately and monitor the entire slitting process in real-time.

2. High-Speed Operation High precision slitting lines are designed for efficiency. They can operate at high speeds without compromising on accuracy. This is crucial in meeting market demands and reducing lead times.

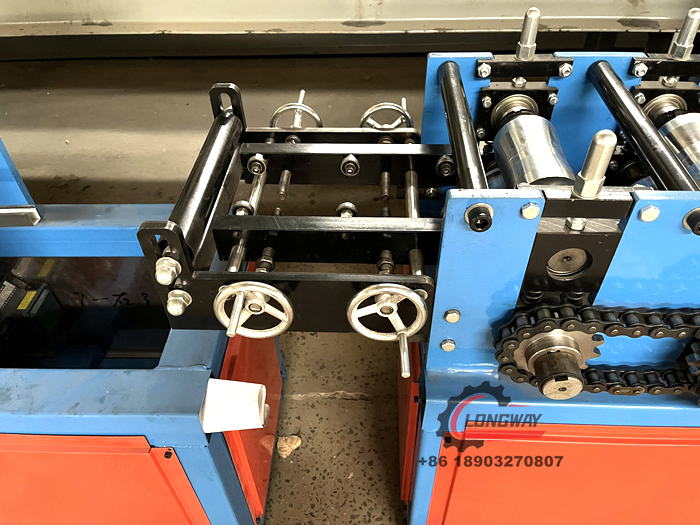

3. Robust Design These machines are built to withstand the rigors of continuous operation. Strong frames, high-quality cutting blades, and stable feeding systems contribute to the durability and longevity of slitting lines.

4. Versatility High precision slitting lines can handle a wide range of material types, including carbon steel, stainless steel, aluminum, and other metal alloys. Additionally, they can process various thicknesses and widths, which adds to their utility in different manufacturing settings.

high precision slitting line machine

5. Waste Minimization By optimizing the slitting process and ensuring precise cuts, high precision slitting lines significantly reduce material waste. This not only lowers the cost of production but also supports sustainable manufacturing practices.

Benefits of Using High Precision Slitting Lines

Investing in high precision slitting technology yields multiple benefits for manufacturers

- Quality Assurance High precision machines ensure that the strips produced meet exact specifications required for various projects, which is critical in industries such as automotive and aerospace where safety and performance are non-negotiable.

- Increased Productivity The efficiency of high-speed slitting lines allows for a greater output of sliced materials, thus improving the overall productivity of manufacturing operations.

- Cost-Effectiveness By reducing waste and improving cut accuracy, companies can significantly lower their production costs. Moreover, the consistency achieved by these machines can translate into fewer rework cycles and enhanced profit margins.

- Enhanced Flexibility With the ability to process different materials and specifications, manufacturers can quickly pivot to meet changing market demands without investing in new machinery.

Conclusion

High precision slitting line machines are revolutionizing the way metal processing is approached in contemporary manufacturing. By integrating advanced technology and robust design with the ability to operate at high speeds, these machines not only enhance production efficiency but also ensure high-quality outputs. As industries continue to evolve, the demand for precision and efficiency in processes like slitting will only grow. Thus, investing in high precision slitting lines is not just a move towards technological advancement; it is a strategic decision for longevity and competitiveness in the metal processing marketplace. As we look to the future, the role of these machines will undoubtedly expand, carving a path for innovation in manufacturing practices.

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025