فبراير . 01, 2025 01:39

Back to list

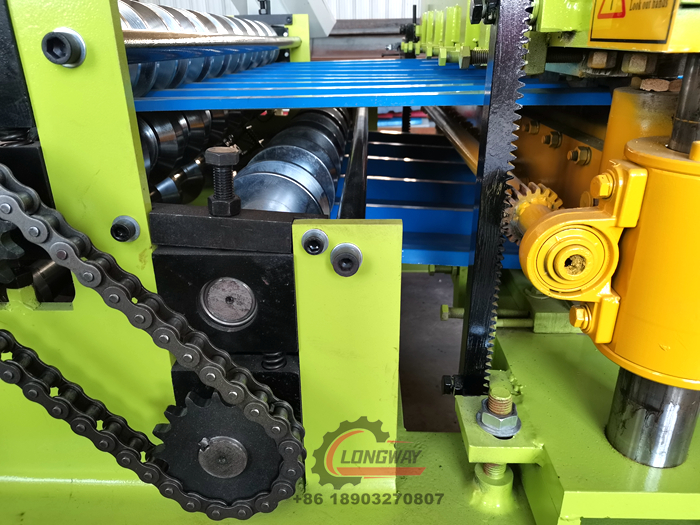

corrugated sheet metal roller

The undulating surfaces of corrugated sheet metal have long captured the attention of industries spanning from agricultural to architectural realms. As the need for durable, strong, and versatile materials grows, the importance of understanding the functionality and benefits of corrugated sheet metal rollers becomes paramount. These tools are crucial for shaping and customizing corrugated sheets, ensuring products meet precise specifications.

Trust, however, remains the cornerstone of this industry. Manufacturers and clients rely heavily on the dependability of their machinery and the integrity of their suppliers. Trustworthiness is built through consistent delivery of quality products, transparent business practices, and providing comprehensive warranties and customer support. Suppliers who invest in regular maintenance and upgrades of their machinery foster confidence among clients, ensuring long-term partnerships and repeat business. The application of corrugated sheet metal rollers extends across a multitude of sectors. In agriculture, for example, corrugated sheets are used in the construction of grain silos and barns. Their wavy patterns provide added strength, allowing these structures to withstand harsh weather conditions. The architectural sector also benefits from the aesthetic and functional utility of corrugated sheets, as seen in modern building facades that marry design with durability. For businesses considering the integration of corrugated sheet metal rollers into their production line, it is crucial to assess the specifications of the machinery. Factors such as the roller's material, capacity, speed, and compatibility with different types of metals (e.g., steel, aluminum, copper) should guide purchasing decisions. Moreover, training personnel to proficiently use these machines can significantly enhance productivity and output quality, leading to an improved bottom line. As the market advances, sustainability becomes a vital consideration. Modern rollers incorporate eco-friendly technologies aimed at reducing energy consumption and waste. Implementing these innovations aligns businesses with global environmental standards and caters to an increasingly eco-conscious consumer base. In conclusion, corrugated sheet metal rollers are invaluable in shaping the future of multiple industries. By emphasizing expertise, authoritativeness, and trustworthiness, businesses can harness their full potential, producing superior products that meet the demands of a dynamic market. The ongoing evolution of these machines promises exciting possibilities, ensuring they remain at the forefront of industrial innovation.

Trust, however, remains the cornerstone of this industry. Manufacturers and clients rely heavily on the dependability of their machinery and the integrity of their suppliers. Trustworthiness is built through consistent delivery of quality products, transparent business practices, and providing comprehensive warranties and customer support. Suppliers who invest in regular maintenance and upgrades of their machinery foster confidence among clients, ensuring long-term partnerships and repeat business. The application of corrugated sheet metal rollers extends across a multitude of sectors. In agriculture, for example, corrugated sheets are used in the construction of grain silos and barns. Their wavy patterns provide added strength, allowing these structures to withstand harsh weather conditions. The architectural sector also benefits from the aesthetic and functional utility of corrugated sheets, as seen in modern building facades that marry design with durability. For businesses considering the integration of corrugated sheet metal rollers into their production line, it is crucial to assess the specifications of the machinery. Factors such as the roller's material, capacity, speed, and compatibility with different types of metals (e.g., steel, aluminum, copper) should guide purchasing decisions. Moreover, training personnel to proficiently use these machines can significantly enhance productivity and output quality, leading to an improved bottom line. As the market advances, sustainability becomes a vital consideration. Modern rollers incorporate eco-friendly technologies aimed at reducing energy consumption and waste. Implementing these innovations aligns businesses with global environmental standards and caters to an increasingly eco-conscious consumer base. In conclusion, corrugated sheet metal rollers are invaluable in shaping the future of multiple industries. By emphasizing expertise, authoritativeness, and trustworthiness, businesses can harness their full potential, producing superior products that meet the demands of a dynamic market. The ongoing evolution of these machines promises exciting possibilities, ensuring they remain at the forefront of industrial innovation.

Next:

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products