Angle Roll Forming Machine Manufacturer and Production Solutions

The Evolution and Significance of Angle Roll Forming Machines

In the world of metal fabrication, efficiency and precision are paramount. One of the most innovative tools that have emerged in this field is the angle roll forming machine. This remarkable piece of equipment has revolutionized the way engineers and manufacturers create metal structures, particularly when it comes to bending and shaping metal angles into various forms. This article explores the intricacies of angle roll forming machines, their functions, applications, and the manufacturing process involved in their production.

Understanding Angle Roll Forming Machines

Angle roll forming machines are specialized equipment designed to process metal sheets or angles into specific shapes through a series of controlled rolling operations. The machine typically consists of three rollers, with the material being fed in from one end, passing between the rollers, and exiting the machine in the desired configuration. The design and functionality of these machines allow for significant versatility in production, making them valuable in a wide range of industries.

Key Features and Advantages

One of the primary features of angle roll forming machines is their ability to produce consistent and high-quality bends in metal. The technology enables manufacturers to create sharp angles, arcs, and curves with precision, ensuring that each product meets the stringent specifications required in construction and engineering. Additionally, these machines can handle various materials, including steel, aluminum, and other metals, allowing for broad applications.

Another significant advantage of using angle roll forming machines is their efficiency. Modern machines are equipped with advanced digital controls and automation systems, allowing for rapid setup and reduced cycle times. This efficiency not only enhances production rates but also minimizes material waste, leading to cost savings for manufacturers. Furthermore, the automation aspect ensures that human error is significantly reduced, resulting in higher quality control.

Applications in Various Industries

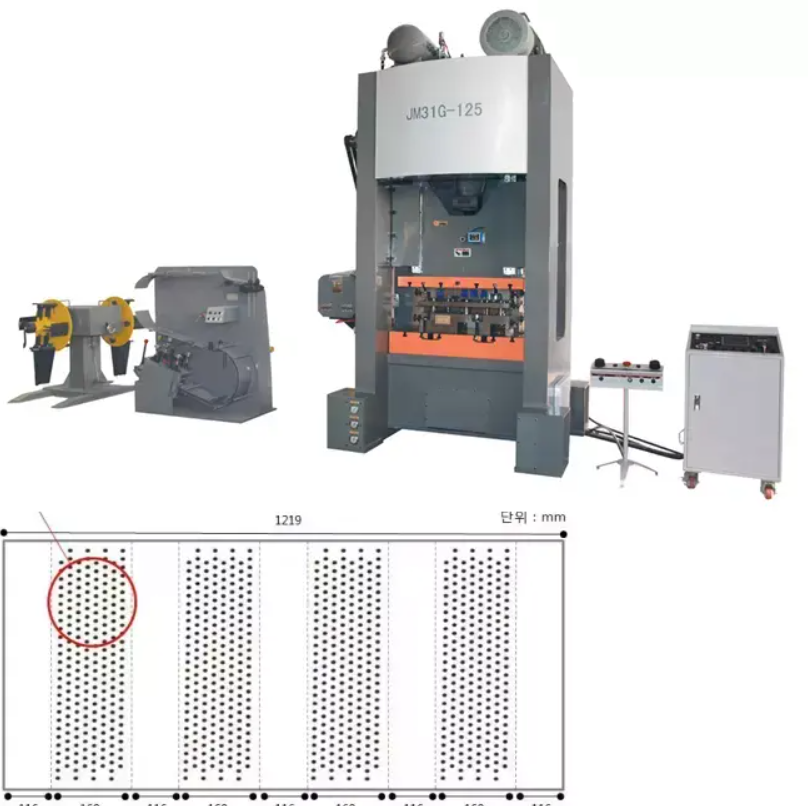

angle roll forming machine factory

Angle roll forming machines find applications in a multitude of industries, each benefiting from their unique capabilities. In the construction sector, they are used to create steel frames, support structures, and architectural elements that are crucial for building stability and design. Similarly, the automotive industry employs these machines to produce components such as chassis frames and brackets, which require precise engineering for optimal performance and safety.

The energy sector also utilizes angle roll forming machines in the production of wind turbine components, brackets, and other structural support elements. Furthermore, they play a critical role in manufacturing furniture, shelving systems, and various household items, showcasing their versatility across different markets.

The Manufacturing Process of Angle Roll Forming Machines

The production of angle roll forming machines involves several critical steps, ensuring that each machine meets quality and performance standards. It begins with the design phase, where engineers utilize computer-aided design (CAD) software to create detailed specifications. Following this, heavy-duty materials are sourced, including high-grade steels and alloys, to withstand the demands of heavy usage.

The fabrication process includes cutting, welding, and assembling various components, followed by rigorous testing to ensure reliability and safety. Manufacturers also prioritize quality control at every stage, using advanced measurement tools to confirm that the machines adhere to industry standards. Other considerations in the manufacturing process include the integration of user-friendly interfaces and automation capabilities, which are essential for modern production environments.

Conclusion

In conclusion, angle roll forming machines play a crucial role in the efficient and precise production of metal components across various industries. Their advanced design and capabilities make them indispensable tools for manufacturers striving for quality and efficiency. As technology continues to evolve, these machines will likely become even more sophisticated, further enhancing their applications and creating new opportunities in the field of metal fabrication. The ongoing development of angle roll forming machines not only signifies progress in manufacturing technology but also underscores the importance of innovation in meeting the ever-growing demands of the global market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025