أخبار

-

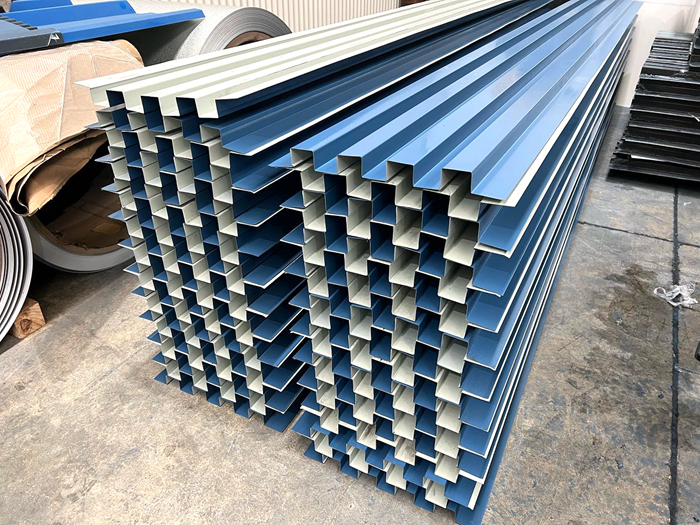

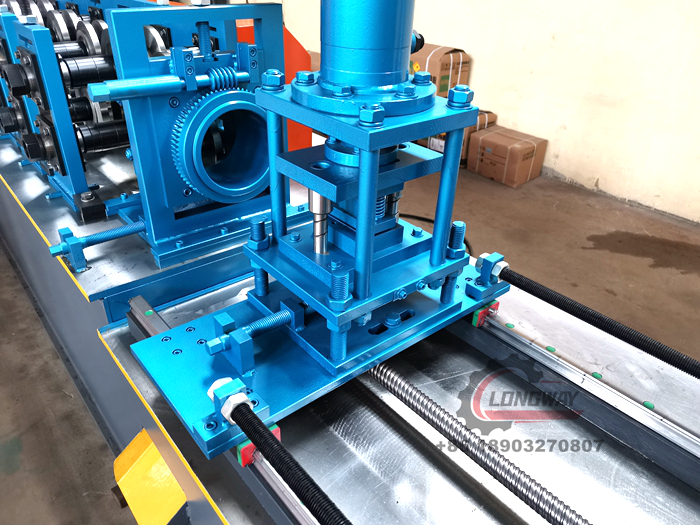

A roll forming machine, also known as a sheet metal roll forming machine, is a piece of equipment used in the manufacturing industry to shape metal sheets or coils into a desired shape or profile. Roll forming is a continuous process where metal, whether it’s in the form of flat sheets or coiled strips, is fed through a series of rollers. Each set of rollers gradually bends and forms the metal into the desired shape or profile This process is widely used in various industries for producing components, parts, and products with specific cross-sectional configurations. Roll forming machine offers advantages like high precision, flexibility in producing various shapes, high efficiency, energy-saving, and faster production times.اقرأ أكثر

A roll forming machine, also known as a sheet metal roll forming machine, is a piece of equipment used in the manufacturing industry to shape metal sheets or coils into a desired shape or profile. Roll forming is a continuous process where metal, whether it’s in the form of flat sheets or coiled strips, is fed through a series of rollers. Each set of rollers gradually bends and forms the metal into the desired shape or profile This process is widely used in various industries for producing components, parts, and products with specific cross-sectional configurations. Roll forming machine offers advantages like high precision, flexibility in producing various shapes, high efficiency, energy-saving, and faster production times.اقرأ أكثر -

Roll Former offers the most productive and cost-effective roll forming equipment for the metal roofing and architectural sheet metal industries. Since 1978 we have been leading the industry with our innovations and service.اقرأ أكثر

Roll Former offers the most productive and cost-effective roll forming equipment for the metal roofing and architectural sheet metal industries. Since 1978 we have been leading the industry with our innovations and service.اقرأ أكثر -

A production type of roll form system will want to be able to continuously produce parts. All parts must be limited in length after they are shaped in the roll form equipment and some parts need strategic holes and slots punched.اقرأ أكثر

A production type of roll form system will want to be able to continuously produce parts. All parts must be limited in length after they are shaped in the roll form equipment and some parts need strategic holes and slots punched.اقرأ أكثر -

The MetalMan Multi-Panel Roofing Machine is a state-of-the-art roll forming machine that runs more sizes, gauges and types of material in up to ten panel configurations with minimum adjustments and less scrap. Forming rollers for each profile can be changed out by only one man in 30 minutes.اقرأ أكثر

The MetalMan Multi-Panel Roofing Machine is a state-of-the-art roll forming machine that runs more sizes, gauges and types of material in up to ten panel configurations with minimum adjustments and less scrap. Forming rollers for each profile can be changed out by only one man in 30 minutes.اقرأ أكثر -

Tubes are used in various industries. Compared to pipes, they are often subject to precise guidelines and thus are used in structural applications such as metal scaffolding, medical devices, and the automotive industry. But how is a tube actually formed?اقرأ أكثر

Tubes are used in various industries. Compared to pipes, they are often subject to precise guidelines and thus are used in structural applications such as metal scaffolding, medical devices, and the automotive industry. But how is a tube actually formed?اقرأ أكثر -

The roll bending process can make metal cylinders or circles, and while these cylinders or circles are made with a sets roller, that process is not called roll forming.اقرأ أكثر

The roll bending process can make metal cylinders or circles, and while these cylinders or circles are made with a sets roller, that process is not called roll forming.اقرأ أكثر -

When manufacturing your specific profile, it is sometimes possible to integrate perforations, holes with or without thread, embossing or even nuts, automatically and precisely into the steel strip at the beginning of the roll forming process – i.e. before the strip of sheet metal is guided in between the pairs of rollers. Next, the steel strip is shaped into the desired cross-section. Depending on the level of complexity, 60 shaping steps or more are not uncommon.اقرأ أكثر

When manufacturing your specific profile, it is sometimes possible to integrate perforations, holes with or without thread, embossing or even nuts, automatically and precisely into the steel strip at the beginning of the roll forming process – i.e. before the strip of sheet metal is guided in between the pairs of rollers. Next, the steel strip is shaped into the desired cross-section. Depending on the level of complexity, 60 shaping steps or more are not uncommon.اقرأ أكثر -

Roll forming is one of the most widely used processes in the world for forming metals. Most of the existing knowledge resides in various journal articles or in the minds of those who have learned from experience. Providing a vehicle to systematically collect and share this important knowledge, the Roll Forming Handbook presents the first comprehensive, dedicated treatment to all facets of roll forming, supplying references to more in-depth information to fill in the gaps.اقرأ أكثر

Roll forming is one of the most widely used processes in the world for forming metals. Most of the existing knowledge resides in various journal articles or in the minds of those who have learned from experience. Providing a vehicle to systematically collect and share this important knowledge, the Roll Forming Handbook presents the first comprehensive, dedicated treatment to all facets of roll forming, supplying references to more in-depth information to fill in the gaps.اقرأ أكثر -

Our heavy duty 3-roll machine is a symmetrical roll design. The material is entered into the pinch point between the top and lower pinch roll. The entry side form roll is then placed into position for pre-forming the leading edge of the part. The part is then fed into the machine forming the leading edge. After the leading edge if formed the entry side form roll is lowered and the exit side form roll is placed into position to finish forming the part. The total process is one entry one pass forming.اقرأ أكثر

Our heavy duty 3-roll machine is a symmetrical roll design. The material is entered into the pinch point between the top and lower pinch roll. The entry side form roll is then placed into position for pre-forming the leading edge of the part. The part is then fed into the machine forming the leading edge. After the leading edge if formed the entry side form roll is lowered and the exit side form roll is placed into position to finish forming the part. The total process is one entry one pass forming.اقرأ أكثر -

“Roll forming is a process that uses a set of precisely placed rollers to perform incremental bending to a continuously fed strip of metal. The rollers are mounted in sets on a consecutive stand with each roller completing one small step of the process.اقرأ أكثر

“Roll forming is a process that uses a set of precisely placed rollers to perform incremental bending to a continuously fed strip of metal. The rollers are mounted in sets on a consecutive stand with each roller completing one small step of the process.اقرأ أكثر -

Since steel mills producing “long sections” of structural steel–including angles, bars, beams, channels, and tees–manufacture their products through a rolling process, these sections are often referred to as, for example, “rolled beams.” (In part to distinguish them from built-up girders, i.e. beams made by welding three pieces together.)اقرأ أكثر

Since steel mills producing “long sections” of structural steel–including angles, bars, beams, channels, and tees–manufacture their products through a rolling process, these sections are often referred to as, for example, “rolled beams.” (In part to distinguish them from built-up girders, i.e. beams made by welding three pieces together.)اقرأ أكثر -

If sheet metal fabrication and aluminum extruding got together and had a baby, you’d get roll forming. Roll forming is like sheet metal fabrication where thin flat sheets of metal are bent into a 3D shape, but in contrast, these bends are formed gradually and continuously so a constant 2D cross-sectional shape comes out the other end like an extrusion. Long strips or coils of flat metal are fed into one end of a roll forming line where it passes through a series of rolling dies and comes out the end in a totally new shape.اقرأ أكثر

If sheet metal fabrication and aluminum extruding got together and had a baby, you’d get roll forming. Roll forming is like sheet metal fabrication where thin flat sheets of metal are bent into a 3D shape, but in contrast, these bends are formed gradually and continuously so a constant 2D cross-sectional shape comes out the other end like an extrusion. Long strips or coils of flat metal are fed into one end of a roll forming line where it passes through a series of rolling dies and comes out the end in a totally new shape.اقرأ أكثر