أخبار

-

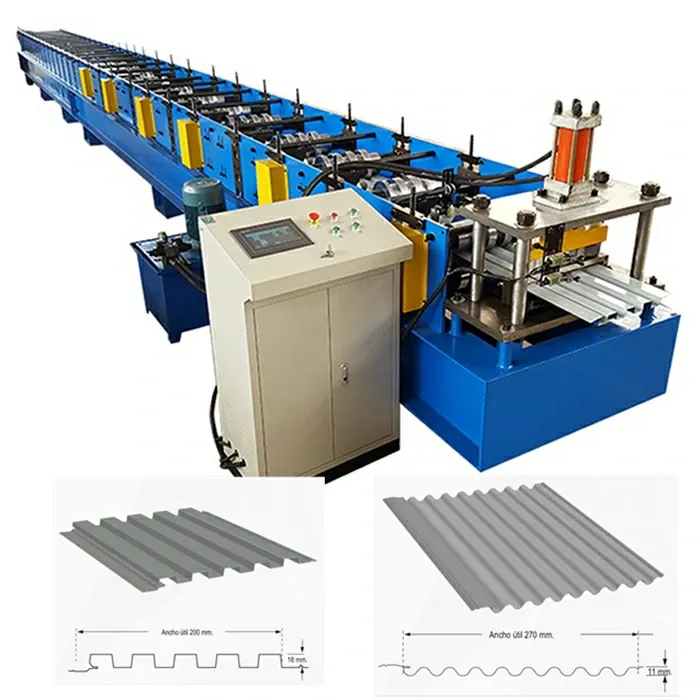

Metal roofing has become increasingly popular in the construction industry due to its durability, longevity, and aesthetic appeal. At the heart of metal roofing production lies the roll forming machine, a versatile tool that shapes metal sheets into precise panels or tiles.اقرأ أكثر

Metal roofing has become increasingly popular in the construction industry due to its durability, longevity, and aesthetic appeal. At the heart of metal roofing production lies the roll forming machine, a versatile tool that shapes metal sheets into precise panels or tiles.اقرأ أكثر -

In the realm of roofing, glazed tiles stand out for their elegance, durability, and weather resistance. Behind the scenes of this architectural beauty lies the craftsmanship of glazed tile making machines.اقرأ أكثر

In the realm of roofing, glazed tiles stand out for their elegance, durability, and weather resistance. Behind the scenes of this architectural beauty lies the craftsmanship of glazed tile making machines.اقرأ أكثر -

In interior construction, achieving level surfaces and sound insulation is crucial for comfort and quality. Furring channels play a significant role in creating these attributes.اقرأ أكثر

In interior construction, achieving level surfaces and sound insulation is crucial for comfort and quality. Furring channels play a significant role in creating these attributes.اقرأ أكثر -

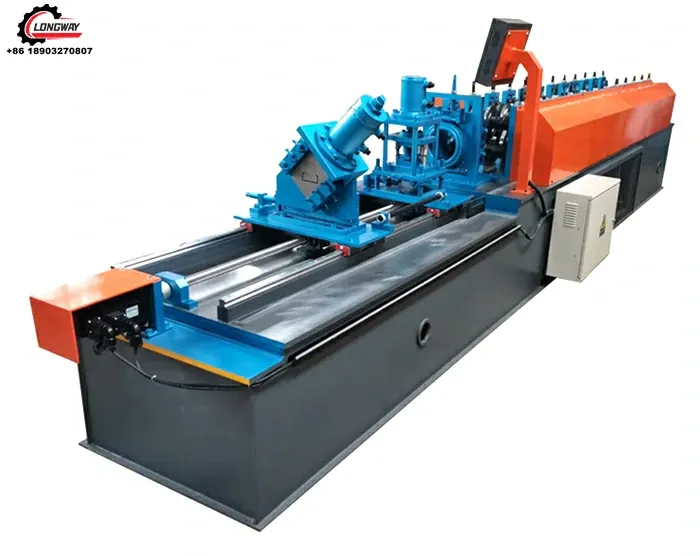

Effective rainwater management is crucial for protecting buildings and preserving their integrity. Gutter forming machines have become indispensable tools in this process, offering efficiency and precision in fabricating gutters and downspouts.اقرأ أكثر

Effective rainwater management is crucial for protecting buildings and preserving their integrity. Gutter forming machines have become indispensable tools in this process, offering efficiency and precision in fabricating gutters and downspouts.اقرأ أكثر -

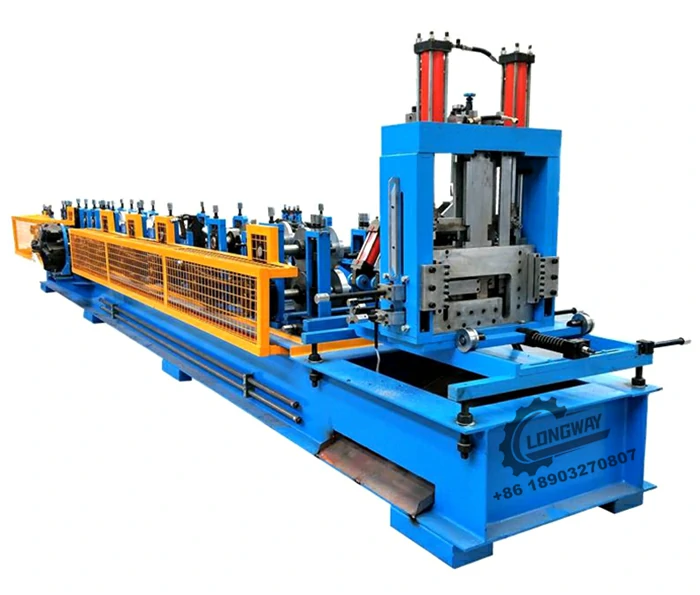

C purlins are essential structural components used in building construction, providing support and stability to roofs and wallsاقرأ أكثر

C purlins are essential structural components used in building construction, providing support and stability to roofs and wallsاقرأ أكثر -

In the realm of construction, innovation is the cornerstone of progress. One such innovation that has transformed the roofing industry is the advent of roof panel machines.اقرأ أكثر

In the realm of construction, innovation is the cornerstone of progress. One such innovation that has transformed the roofing industry is the advent of roof panel machines.اقرأ أكثر -

In the construction and home improvement sectors, effective rainwater management is crucial for protecting buildings from water damage.اقرأ أكثر

In the construction and home improvement sectors, effective rainwater management is crucial for protecting buildings from water damage.اقرأ أكثر -

In the modern construction landscape, efficiency and precision are indispensable.اقرأ أكثر

In the modern construction landscape, efficiency and precision are indispensable.اقرأ أكثر -

nges in how drywall profiles are manufactured, ensuring higher quality and productivity.اقرأ أكثر

nges in how drywall profiles are manufactured, ensuring higher quality and productivity.اقرأ أكثر -

In the evolving world of construction, efficiency and precision are paramount.اقرأ أكثر

In the evolving world of construction, efficiency and precision are paramount.اقرأ أكثر -

In the ever-evolving construction industry, the demand for durable and efficient roofing solutions has led to the rise of advanced machinery such as metal roof roll forming machines.اقرأ أكثر

In the ever-evolving construction industry, the demand for durable and efficient roofing solutions has led to the rise of advanced machinery such as metal roof roll forming machines.اقرأ أكثر -

In the realm of construction, efficiency, and precision are paramount.اقرأ أكثر

In the realm of construction, efficiency, and precision are paramount.اقرأ أكثر