Steel Slitting Line Manufacturing Facilities for High-Quality Metal Processing Solutions

Understanding Steel Slitting Line Factories An Overview

Steel slitting lines are essential facilities in the metal processing industry, playing a crucial role in the production and preparation of steel coils for various applications. The process involves cutting large coils of steel into narrower strips, which can then be further processed or used in manufacturing applications. This article explores the nature of steel slitting line factories, their importance in the supply chain, and the key components that make up an efficient slitting line operation.

What is a Steel Slitting Line?

A steel slitting line is a manufacturing setup used to convert wide coils of steel into narrower strips with specific dimensions and tolerances. The primary purpose is to produce slit steel products that meet the demands of customers in various sectors, including automotive, construction, and appliances. The slitting process involves uncoiling the steel, passing it through a series of cutting blades, and then recoiling the resultant strips into smaller coils for easier handling and shipping.

The Significance of Steel Slitting Line Factories

In today's industrial landscape, steel is an integral material used in countless applications. As demand for steel products continues to grow, the role of slitting line factories has become increasingly vital. They provide manufacturers with customized steel strips that can be directly used in their production processes, ensuring a seamless supply chain.

One of the primary advantages of using slitting lines is the level of precision they offer. Advanced technology allows these factories to achieve tight tolerances and excellent surface finishes, making them favorable for applications that require high-quality materials. Moreover, they enhance operational efficiency by reducing the need for additional processing, thus saving both time and costs for manufacturers.

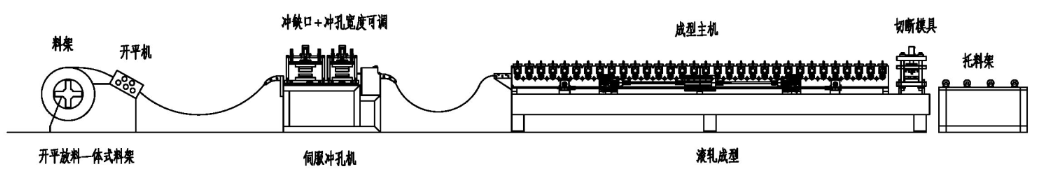

Key Components of a Steel Slitting Line

1. Uncoiler The process begins with the uncoiler, which holds large coils of steel and unwinds them as the production process starts. Quality uncoilers are designed to handle varying weights and sizes of coils, ensuring smooth and consistent feeding into the slitting line.

2. Slitting Blades These are precision blades used to cut the steel coil into narrower strips. The arrangement and configuration of these blades can be adjusted to achieve the desired strip width. Advanced slitting lines may feature multiple blade sets, allowing for simultaneous cutting of several strips.

steel slitting line factories

3. Breakdown Section After slitting, the strips need to be flattened and formed into the desired shape. This section often includes rollers that help in the leveling of the steel, ensuring that the strips are free from any distortion and are uniform in thickness.

4. Recoiler Once the steel has been cut and processed, it is rolled back into coils by the recoiler. This equipment is critical for organizing the final products for shipping, making it easier for handling and storage.

5. Control Systems Modern slitting lines are equipped with sophisticated control systems that monitor every stage of the process. These systems help ensure precision in cutting, adjust speeds, and maintain quality standards throughout production.

Challenges Faced by Steel Slitting Line Factories

While steel slitting line factories are crucial to the industry, they face several challenges. Fluctuations in raw material prices can impact production costs, and with the ever-increasing demand for customization, slitting lines must adapt quickly to changing customer specifications. Additionally, maintaining high levels of efficiency and minimizing downtime remain critical to maximizing productivity.

Future Trends in Steel Slitting Lines

As technology advances, steel slitting line factories are expected to evolve significantly. Automation and digitalization are among the leading trends shaping the future of slitting lines, enabling factories to boost operational efficiency and reduce human error. The integration of artificial intelligence and machine learning can enhance predictive maintenance, ensuring that machines operate at optimal levels and reducing unexpected downtimes.

Moreover, with the growing emphasis on sustainability, steel slitting line factories are likely to adopt greener technologies and practices, aiming for more environmentally friendly processes and waste reduction.

Conclusion

Steel slitting line factories are a pivotal part of the manufacturing ecosystem, providing tailored steel solutions for a myriad of applications. By understanding the components, significance, and challenges of these facilities, stakeholders can appreciate the integral role they play in supporting industries that rely on steel products. As the industry moves forward, embracing innovation and adapting to trends will be key to meeting the evolving demands of the market.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025