Leading Company in Portable Roll Forming Equipment Manufacturing and Solutions

The Rise of Portable Roll Former Manufacturers

In recent years, the construction and manufacturing industries have increasingly turned towards innovative machinery to improve efficiency and reduce costs. One such innovation is the portable roll former, a machine that allows manufacturers to create metal components on-site, thereby eliminating the need for transporting large materials and reducing waste. This article explores the significance of portable roll former manufacturers, the benefits they provide, and the future of this evolving industry.

What is a Portable Roll Former?

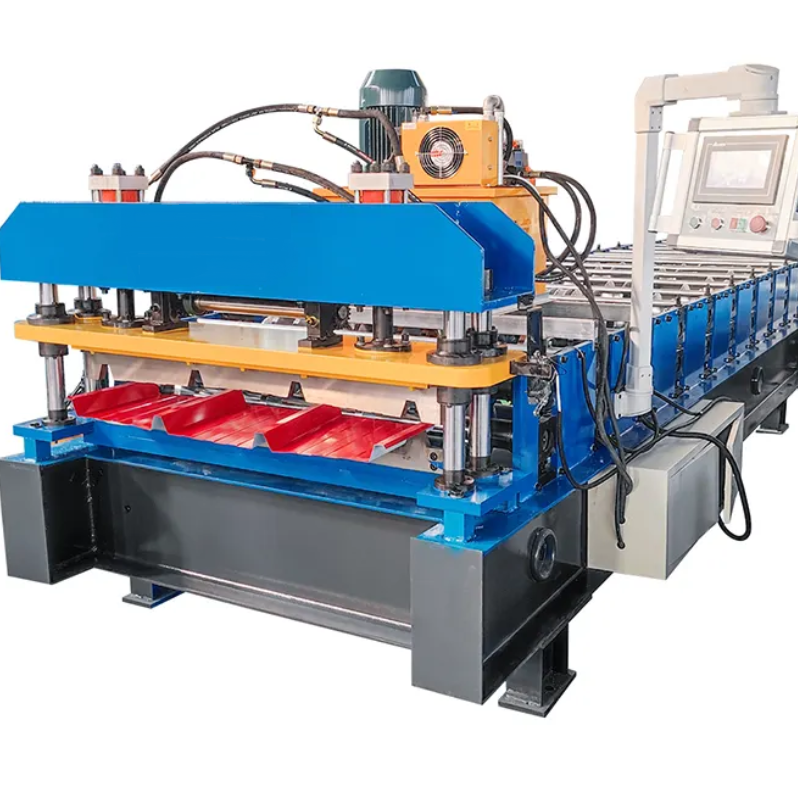

A portable roll former is a specialized piece of equipment designed to produce various metal profiles from coil stock. Unlike traditional roll formers, which are fixed installations, portable models are compact and mobile, making them accessible for use in a variety of locations. These machines can produce profiles for roofing, siding, and other structural components, making them essential for residential, commercial, and industrial construction projects.

The Benefits of Portable Roll Formers

1. On-Site Production One of the most significant advantages of using a portable roll former is the ability to manufacture components directly at the job site. This on-site production minimizes transport costs and logistical challenges associated with moving large metal sections.

2. Customization Portable roll formers enable manufacturers to create customized components that meet the specific requirements of a project. This flexibility is crucial in construction, where unique designs and specifications are often required.

3. Reduced Waste By producing materials on-site, manufacturers can better control the amount of scrap generated during the manufacturing process. This reduction in waste not only lowers costs but also contributes to more sustainable building practices.

4. Enhanced Efficiency The speed at which portable roll formers can operate allows manufacturers to produce large volumes of material quickly. This efficiency helps streamline the construction process, leading to faster project completion times.

5. Versatility Portable roll formers can create a wide variety of profiles, including those for roofing, gutters, and other architectural components. This versatility allows manufacturers to serve multiple markets and adapt to changing customer needs.

portable roll former manufacturer

The Role of Portable Roll Former Manufacturers

Manufacturers of portable roll formers play a crucial role in the construction and manufacturing sectors. They are responsible for designing and producing these machines, ensuring they meet the highest standards of quality and efficiency. As demand for portable roll forming equipment grows, so too does the need for innovation within the industry.

Leading portable roll former manufacturers are investing heavily in research and development to enhance the capabilities of their machines. This includes integrating advanced technologies such as automation and smart controls to improve user experience and operational efficiency. For instance, many new models come equipped with digital displays and programmable settings that allow operators to adjust specifications on the fly, further improving the versatility of the machinery.

Future Trends in Portable Roll Forming

Moving forward, several trends are likely to shape the portable roll forming industry. First and foremost, the push for sustainability in construction will continue to drive demand for more efficient and eco-friendly manufacturing processes. Portable roll formers, with their reduced waste and on-site production capabilities, will play a vital role in this initiative.

Secondly, as the construction industry increasingly adopts technology, portable roll formers will need to evolve. Incorporating features such as IoT connectivity, predictive maintenance, and automated settings will make these machines even more user-friendly and efficient.

Finally, the globalization of the manufacturing market means that portable roll former manufacturers must also adapt to international standards and customer needs. This may involve customizing machines for different regions, complying with varying regulations, and addressing the specific challenges faced by contractors worldwide.

Conclusion

Portable roll former manufacturers are at the forefront of a significant shift in the construction industry. By providing on-site production capabilities, customization options, and reduced waste, these manufacturers are helping to streamline processes and meet the evolving needs of the market. As technology advances and sustainability becomes increasingly important, the role of portable roll formers will undoubtedly grow, positioning them as an indispensable asset in modern manufacturing and construction.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025