omega channel profile rolling machine for efficient metal shaping and construction solutions

Understanding the Omega Channel Roll Forming Machine

The Omega channel roll forming machine is a specialized piece of equipment designed for the efficient production of omega-shaped channels, which are crucial in various industrial applications. With the rise of modern manufacturing, the need for precision, efficiency, and versatility in producing such shapes has become increasingly important.

What is Roll Forming?

Roll forming is a continuous bending operation in which a long strip of metal is passed through a series of sequentially arranged rollers. These rollers progressively form the metal into the desired shape, such as the omega channel, which is characterized by its distinctive “U” shape with flanges. Roll forming is particularly beneficial for producing components in high volume due to its efficiency and minimal material waste.

The Features of Omega Channel Roll Forming Machines

An omega channel roll forming machine typically consists of various components designed to enhance productivity and precision. Key features include

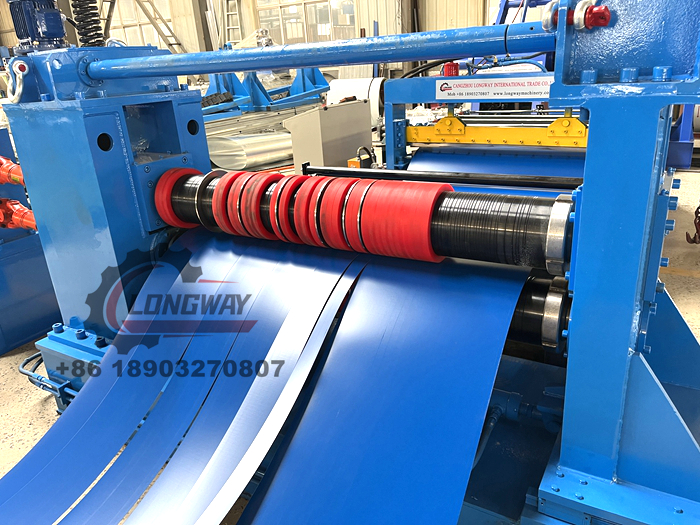

1. Rollers and Dies The heart of the roll forming process, these are crafted out of high-quality steel and designed to create the specific omega shape. Each roller is calibrated to ensure accurate dimensions and surface finish.

2. Feeding System A reliable feeding system ensures that the metal strip enters the machine at the right speed and alignment, which is critical for achieving uniformity in the product.

3. Cut-off Mechanism To achieve the required length of each omega channel, a cut-off mechanism slices the continuous strip at predetermined intervals. This can be automated for enhanced speed and accuracy.

4. Control Panel Modern machines come equipped with user-friendly control panels that allow operators to set parameters such as speed, length, and the number of pieces to be produced. Advanced models may include PLC (Programmable Logic Controller) systems for better control and monitoring.

5. Size Flexibility Omega channel roll forming machines can often be adjusted to produce varying dimensions, catering to the specific needs of different applications.

Applications of Omega Channels

Omega channels are utilized in numerous industries, primarily due to their strength and versatility. Some common applications include

omega channel roll forming machine

- Construction Omega channels serve as essential components in framing for walls, ceilings, and roofs in commercial and residential buildings

. They provide structural integrity and are often used in the creation of pre-fabricated building systems.- Automotive In the automotive sector, these channels are used in the production of various parts, including support structures and frameworks for vehicles. The lightweight yet strong design of omega channels makes them ideal for automotive applications where weight savings are essential.

- HVAC Systems Omega channels are also widely used in HVAC (Heating, Ventilation, and Air Conditioning) systems, serving as support frameworks for ductwork and other installations.

- Electrical Installations The channels are often employed in the installation of electrical conduits and support systems for wiring and lighting fixtures.

The Advantages of Using Omega Channel Roll Forming Machines

The use of roll forming technology, particularly in the production of omega channels, offers several advantages

- Cost Efficiency Once set up, the machine can produce a large volume of channels with minimal labor costs and material waste, making it a cost-effective solution for manufacturers.

- High Precision and Consistency Roll forming allows for high precision in dimensions and a consistent product quality, which is critical for parts that need to fit tightly in assemblies.

- Speed of Production The continuous nature of the roll forming process enables high-speed production, reducing lead times for customers.

- Durability and Strength Omega channels produced via roll forming are known for their strength, thanks to the cold-formed nature of the manufacturing process, which enhances the metal's structural integrity.

Conclusion

In the competitive landscape of modern manufacturing, the omega channel roll forming machine stands out as an indispensable tool for producing high-quality components. Its efficiency, precision, and versatility make it a preferred choice in various industries, from construction to automotive and beyond. As technology advances, we can expect further improvements in roll forming processes, enhancing the capabilities and applications of omega channel manufacturing even further.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025