metal roll forming machine for sale

Exploring Metal Roll Forming Machines for Sale

In the world of manufacturing and construction, efficiency and precision are paramount. One of the key technologies that meet these demands is the metal roll forming machine. This innovative equipment allows for the continuous shaping of metal sheets into specific profiles and is widely used across various industries, including roofing, automotive, and construction. As businesses seek to optimize their production processes, the availability of metal roll forming machines for sale has surged. In this article, we will explore the features, benefits, and considerations to keep in mind when purchasing these machines.

What is a Metal Roll Forming Machine?

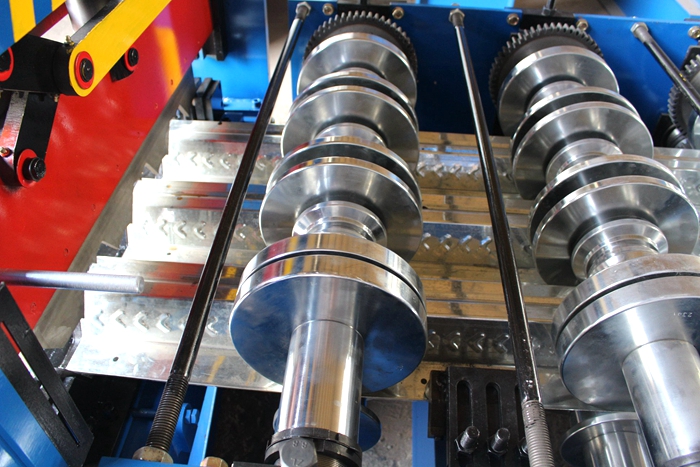

A metal roll forming machine is designed to convert flat metal sheets into formed shapes by passing the material through a series of rollers. Each roller gradually changes the shape of the metal until it reaches the desired profile. This process is known for its efficiency, as it allows for high-speed production with minimal waste. Various products can be created using roll forming, such as roofing panels, door frames, and steel studs, making it a versatile tool in any manufacturing facility.

Key Features of Metal Roll Forming Machines

When considering purchasing a roll forming machine, it's essential to analyze its key features

1. Material Compatibility Most roll forming machines can handle a range of materials, including steel, aluminum, and stainless steel. Identifying the specific materials your business works with will ensure you choose a suitable machine.

2. Profile Customization Many modern machines offer the ability to create custom profiles tailored to specific project requirements. The flexibility to switch between different product designs can significantly enhance production efficiency.

3. Automation Advanced roll forming machines come equipped with automation features, such as programmable controls and sensors. These technologies enhance accuracy and reduce human error, resulting in a more efficient production process.

4. Production Speed The speed at which a roll forming machine operates is critical for meeting production deadlines. Machines vary in their capacity, so it's crucial to choose one that aligns with your manufacturing goals.

5. Durability and Maintenance A durable machine will stand the test of time and minimize downtime due to repairs. Investing in a machine built with quality materials will yield better long-term results.

Benefits of Using Metal Roll Forming Machines

Investing in a metal roll forming machine comes with numerous advantages

metal roll forming machine for sale

1. Cost-effectiveness Roll forming offers a low-cost production method due to its energy efficiency and high-speed operations. The reduction in material waste also contributes to cost savings.

2. High Precision Roll forming produces consistent shapes and dimensions, making it an excellent choice for projects requiring precision. This level of accuracy is essential in industries that demand stringent quality control.

3. Versatility From construction components to automotive parts, the versatility of roll forming machines makes them invaluable in various industries. The ability to create a wide range of profiles caters to diverse market needs.

4. Reduced Labor Costs The automation of roll forming processes minimizes the need for manual labor, thus reducing labor costs and the associated risks of human error.

Considerations When Buying a Metal Roll Forming Machine

Before making a purchase, several considerations should be taken into account

1. Budget Determine your budget and explore how different models fit within it. Remember that cheaper options may compromise on quality or features.

2. Production Needs Analyze your production capacity to select a machine that can efficiently handle your workload.

3. Supplier Reputation Research potential suppliers and read reviews to ensure you are purchasing from a reputable source. A good supplier will offer support and service long after the sale.

4. Warranty and Support A comprehensive warranty and responsive customer service can protect your investment and ensure smooth operation post-purchase.

5. Training and Installation Ensure that your purchase includes training for your staff on how to operate the machine safely and efficiently, as well as assistance with installation.

Conclusion

Metal roll forming machines bring a blend of efficiency, precision, and versatility to manufacturing processes. With various options available for sale, businesses can find a model that fits their specific needs. By understanding the features, benefits, and considerations involved, manufacturers can make informed decisions that enhance productivity and improve profitability in their operations. Investing in the right metal roll forming machine is not just a purchase but a strategic move towards a streamlined future in production.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025