Oca . 17, 2025 02:14

Back to list

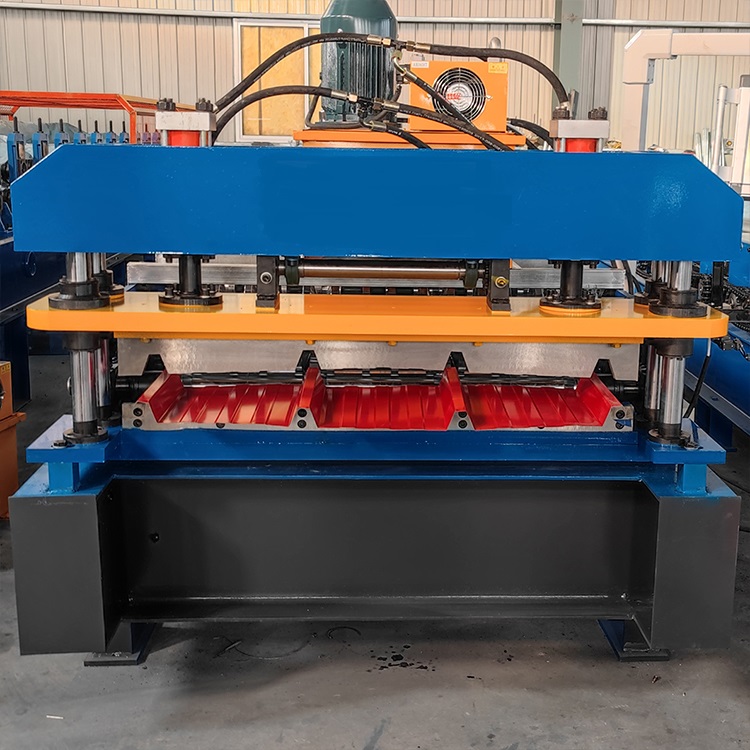

metal roll forming

Roll forming is a continuous bending operation in which metal strips are passed through successive sets of rolls at room temperature. Each set of rolls contributes to the final contour, and the metal takes its desired shape as it emerges. It's an advanced technique widely praised for its efficiency and precision in creating uniform profiles over long lengths. For companies operating in construction, automotive, or manufacturing fields, understanding and utilizing metal roll forming can revolutionize production processes.

In terms of innovation, advancements in roll forming technology, like computer-controlled roll adjustments, have amplified its capabilities. Modern roll forming machines are equipped with real-time monitoring and adjustments, ensuring optimal performance and product consistency. This technological integration facilitates quick changeovers, allowing manufacturers to switch between different profiles seamlessly, thus catering to dynamic market demands without significant downtime. Moreover, the adaptability of roll forming machines supports diverse customization needs. By altering roll configurations, businesses can produce a wide variety of shapes and sizes from simple U-channels to complex custom profiles. This flexibility can be a game-changer for manufacturers dealing with varied customer specifications or those in niche markets where bespoke solutions often command higher premiums. Roll forming is not without its challenges, primarily the initial setup cost and the requirement for precise engineering design. However, the long-term benefits—particularly for large-scale production—far outweigh these initial hurdles. By investing in high-quality roll forming setups, businesses can achieve scalability that accommodates growth without proportionate increases in cost or resource demands. Professionals involved in metal fabrication and product development need to be aware of the critical role of skilled operators and engineers. These experts ensure machines run optimally and troubleshoot any mechanical issues swiftly to prevent disruption. Continuous training and development of personnel are essential to harness full operational potential, maintain product standards, and uphold the company’s reputation. Ultimately, in a fast-evolving industrial landscape, embracing cutting-edge manufacturing techniques like metal roll forming is crucial for maintaining competitive advantage. Those leading the way in metal forming must focus on continuous innovation, optimal use of resources, and adherence to quality standards to stay ahead. This strategic embrace of specialized techniques will guide industries to new heights of efficiency and success—securing a prominent place in both domestic and international markets.

In terms of innovation, advancements in roll forming technology, like computer-controlled roll adjustments, have amplified its capabilities. Modern roll forming machines are equipped with real-time monitoring and adjustments, ensuring optimal performance and product consistency. This technological integration facilitates quick changeovers, allowing manufacturers to switch between different profiles seamlessly, thus catering to dynamic market demands without significant downtime. Moreover, the adaptability of roll forming machines supports diverse customization needs. By altering roll configurations, businesses can produce a wide variety of shapes and sizes from simple U-channels to complex custom profiles. This flexibility can be a game-changer for manufacturers dealing with varied customer specifications or those in niche markets where bespoke solutions often command higher premiums. Roll forming is not without its challenges, primarily the initial setup cost and the requirement for precise engineering design. However, the long-term benefits—particularly for large-scale production—far outweigh these initial hurdles. By investing in high-quality roll forming setups, businesses can achieve scalability that accommodates growth without proportionate increases in cost or resource demands. Professionals involved in metal fabrication and product development need to be aware of the critical role of skilled operators and engineers. These experts ensure machines run optimally and troubleshoot any mechanical issues swiftly to prevent disruption. Continuous training and development of personnel are essential to harness full operational potential, maintain product standards, and uphold the company’s reputation. Ultimately, in a fast-evolving industrial landscape, embracing cutting-edge manufacturing techniques like metal roll forming is crucial for maintaining competitive advantage. Those leading the way in metal forming must focus on continuous innovation, optimal use of resources, and adherence to quality standards to stay ahead. This strategic embrace of specialized techniques will guide industries to new heights of efficiency and success—securing a prominent place in both domestic and international markets.

Latest news

-

The Role of Hydraulic Systems in Sheet Metal SlittersNewsAug.23, 2025

-

Customization Options in Metal Deck Roll Forming MachinesNewsAug.23, 2025

-

Safety Tips When Using a Gutter Making MachineNewsAug.23, 2025

-

Key Components of a C Purlin Machine ExplainedNewsAug.23, 2025

-

Maintenance Tips for a Steel Angle Roll Forming MachineNewsAug.23, 2025

-

Portable Metal Roofing Machine Applications in Remote ConstructionNewsAug.23, 2025

-

Roof Panel MachineNewsAug.18, 2025

Related Products