double layer forming machine company

The Emergence of Double Layer Forming Machine Companies

In the ever-evolving landscape of manufacturing, the demand for efficiency, versatility, and innovation has led to the rise of specialized machinery that can cater to complex production needs. One such innovation that has gained significant traction is the double layer forming machine. This advanced piece of equipment is revolutionizing the way materials are processed and has given rise to a new wave of companies dedicated to its development and manufacturing.

What is a Double Layer Forming Machine?

A double layer forming machine is specifically designed to produce two different layers of materials simultaneously, effectively doubling the production capacity without increasing the footprint of the machinery. This dual-layer technology is particularly beneficial in industries such as construction, roofing, and packaging where diverse material compositions can greatly enhance product functionality and aesthetic appeal.

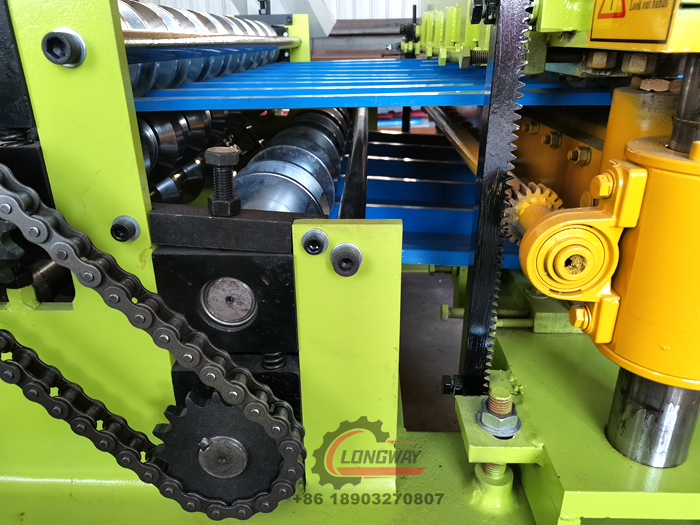

The machine typically consists of two sets of rollers, each configured to handle different material types or thicknesses, allowing for the creation of composite materials that can offer improved strength, durability, and resistance to weathering. This is particularly important in the construction industry, where the demand for lightweight yet robust materials is constantly increasing.

The Role of Companies in the Market

As the popularity of double layer forming technology surges, a number of companies have emerged to specialize in the design, manufacturing, and distribution of these machines

. These companies are not only focused on producing state-of-the-art machinery but also on providing comprehensive solutions that include after-sales support, training, and maintenance services.One of the leading players in this sector is known for its continuous innovation and commitment to quality. They invest significantly in research and development to enhance the capabilities of their machines, ensuring that they meet the evolving needs of their clients. By leveraging the latest advancements in technology, these companies can offer machines that are more efficient, reliable, and user-friendly.

Benefits of Using Double Layer Forming Machines

double layer forming machine company

The adoption of double layer forming machines offers several advantages for manufacturers. Firstly, they significantly increase production efficiency. By producing two layers simultaneously, companies can reduce the time it takes to produce materials, leading to faster turnaround times and an increase in overall output.

Secondly, the ability to create composite materials opens up new opportunities for product development. Manufacturers can experiment with various material combinations, resulting in innovative products that can meet specific customer requirements. This flexibility is a game-changer in industries that prioritize customization and adaptability.

Moreover, these machines contribute to cost savings. By streamlining the production process, companies can reduce labor costs and minimize waste. The precision engineering of double layer forming machines ensures that materials are used effectively, which further aids in reducing operational expenses.

Challenges and Future Prospects

Despite the numerous benefits, companies in this sector face challenges such as competition from lower-cost manufacturers and the need for constant technological upgrades. The market is becoming increasingly saturated, and firms must differentiate themselves by offering unique features or exceptional customer service.

To stay ahead, double layer forming machine companies are focusing on automation and smart technology. Integrating IoT capabilities allows for real-time monitoring and diagnostics, helping manufacturers optimize their processes and reduce downtime. As sustainability becomes a priority in manufacturing, these companies are also seeking ways to produce energy-efficient machines and minimize the environmental impact of their operations.

Conclusion

In conclusion, the rise of double layer forming machine companies reflects a broader trend towards innovation and efficiency in manufacturing. These machines not only enhance productivity but also enable the creation of advanced materials that meet the demands of a dynamic market. As technology continues to evolve, these companies will play a crucial role in shaping the future of manufacturing, driving progress, and supporting sustainable practices. The journey of double layer forming machines is just beginning, and their impact on various industries will undoubtedly grow in the years to come.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025