color coated sheet making machine price

The Price and Value of Color Coated Sheet Making Machines

In a rapidly evolving manufacturing landscape, the demand for advanced machinery that enhances productivity, quality, and efficiency is paramount. One such machine that stands out in the metal processing industry is the color coated sheet making machine. This specialized equipment plays a crucial role in producing aesthetically pleasing and functional coated sheets used in various applications such as construction, automotive, and home appliances. However, before investing in such machinery, understanding the pricing, features, and the overall value it brings to a business is essential.

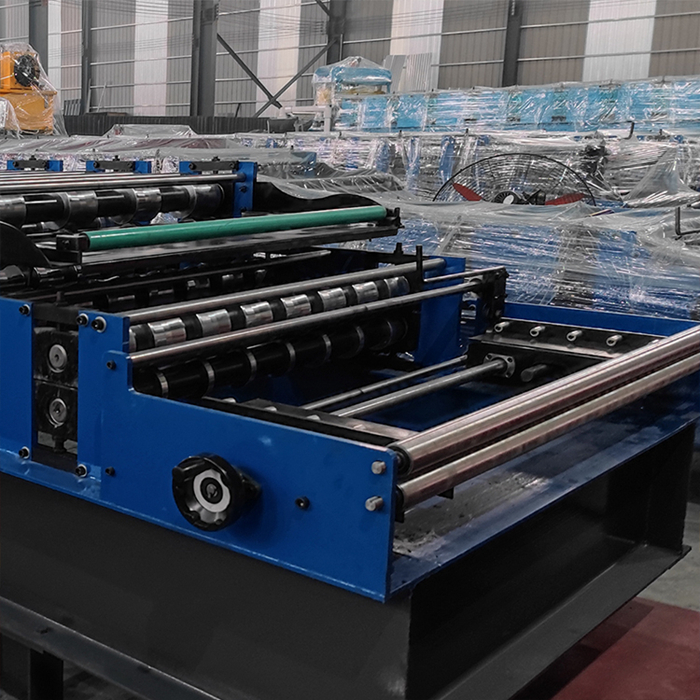

Understanding Color Coated Sheet Making Machines

Color coated sheet making machines are designed to process and apply color finishes to steel or aluminum sheets. This process involves cleaning, coating, and curing the metal, resulting in a product that is both visually appealing and protected from corrosion. These machines can handle various substrates and typically offer multiple options for coating, such as polyester, PVDF (polyvinylidene fluoride), and epoxy.

Factors Influencing the Price

The price of a color coated sheet making machine can vary significantly based on several factors

1. Type of Machine There are different types of machines available, ranging from simple manual models to fully automated lines. Automated machines, which can handle high throughput and require less manual intervention, tend to command higher prices.

2. Production Capacity Machines with higher production capacities and advanced features (such as integrated printing or embossing) usually come at a premium. Companies must assess their production needs to determine the most cost-effective option.

3. Technology and Features Modern machines often incorporate cutting-edge technology, such as IoT (Internet of Things) connectivity, advanced temperature control, and energy-efficient designs. These features enhance performance and reduce operational costs but can also increase the initial price of the machine.

color coated sheet making machine price

4. Brand Reputation and Support Established manufacturers that offer robust customer support and warranty options often charge more for their machines. However, investing in a reputable brand can lead to lower maintenance costs and better long-term reliability.

5. Customization Options Many manufacturers offer customized machinery tailored to specific production needs. Custom features might add to the overall price but can result in better efficiencies for niche applications.

Pricing Overview

As of the latest data available, the price range for color coated sheet making machines can vary from about $50,000 to over $300,000, depending on the aforementioned factors. For small to medium enterprises, finding a balance between pricing and functionality is essential. It’s important to assess the return on investment (ROI) that a new machine will bring. Sometimes, a more affordable option that meets basic production needs might be more beneficial than a high-end machine that exceeds the company’s requirements.

Evaluating the Value Proposition

Investing in a color coated sheet making machine is not merely a cost; it is an investment in efficiency and quality. A high-quality machine can lead to reduced waste, improved production speed, and enhanced product quality, ultimately translating to higher profitability.

Moreover, the ability to produce color coated sheets in-house can significantly reduce outsourcing costs and lead times. Businesses that can quickly adapt their offerings to changing market demands will have a competitive advantage.

Conclusion

In conclusion, while the price of color coated sheet making machines can be substantial, the potential benefits far outweigh the costs. Companies must conduct thorough research and consider their production needs, budget, and the long-term value the machinery will provide. By choosing the right machine, manufacturers can not only improve their operations but also position themselves for growth in the dynamic and competitive market landscape. The right choice of machinery can make all the difference in achieving operational excellence and meeting customer expectations.