Top Suppliers for Cold Roll Forming Machines and Equipment Solutions

Understanding Cold Roll Forming Machines An Essential Guide for Suppliers

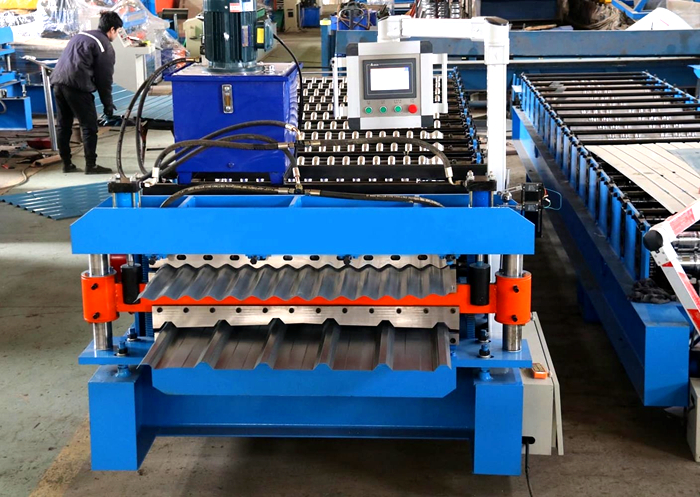

Cold roll forming is an innovative manufacturing process widely utilized in various industries to produce complex shapes and profiles from metal sheets. As the demand for customized metal profiles increases, so does the need for high-quality cold roll forming machines. This article aims to provide an understanding of cold roll forming machines, their applications, and important considerations for suppliers.

What is Cold Roll Forming?

Cold roll forming involves the continuous bending of metal strips or sheets at room temperature into specific shapes. The process uses a series of rollers and dies to gradually shape the metal, often resulting in products that have superior strength and precision compared to other manufacturing methods. The process is highly efficient and allows for the rapid production of large quantities of uniform parts with tight tolerances.

Applications of Cold Roll Forming Machines

Cold roll forming machines are used in various sectors due to their versatility and efficiency. Key applications include

1. Construction Industry Cold roll forming is extensively used to manufacture structural components such as purlins, beams, and channels. These components are crucial for building frameworks, providing both strength and lightweight characteristics.

2. Automotive Industry Manufacturers employ cold roll forming to create parts like chassis components, brackets, and frames. The process is ideal due to its ability to produce parts that are lighter yet structurally sound, contributing to fuel efficiency.

3. Electrical and HVAC Cold roll forming machines produce conduits, brackets, and support structures for electrical and HVAC systems, helping streamline installation and ensure durability.

cold roll forming machine supplier

5. Signage and Displays Cold roll forming allows for the creation of intricate and attractive signage that requires durability and resistance to environmental factors.

Importance of Quality in Cold Roll Forming Machines

As suppliers of cold roll forming machines, ensuring high quality is paramount. Machine quality directly impacts the productivity, efficiency, and final output of manufactured products. Key factors to consider include

1. Material Quality The raw materials used in the machine should be of high-grade steel to ensure longevity and withstand operational stresses.

2. Precision Engineering Machines should be designed and engineered with precision to achieve accurate dimensions of the formed products. Any deviations can lead to increased waste and additional costs.

3. Flexibility and Customization Suppliers must offer machines that can be customized to meet the specific needs of different industries and applications. This flexibility is crucial for clients looking to produce unique profiles.

4. Technology Integration Modern cold roll forming machines incorporate advanced technologies such as computer numerical control (CNC) for enhanced accuracy and efficiency. Suppliers should keep up with technological advancements to provide innovative solutions.

5. Support and Maintenance Offering excellent after-sales support and maintenance services is vital for building long-term relationships with clients. Regular maintenance ensures that machines operate at peak performance, reducing downtime.

Conclusion

Cold roll forming machines are essential tools in modern manufacturing, providing efficient solutions for producing high-quality metal profiles. As a supplier in this field, it is crucial to stay informed about the latest technologies, maintain high-quality standards, and understand the specific needs of various industries. By doing so, suppliers can enhance their offerings and foster strong partnerships with their clients, ultimately driving mutual success in a competitive marketplace.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025