Haberler

-

Are you considering building a new home or replacing your existing roofing sheet? Choosing the right type of roofing sheet for your home can be tricky, and it's easy to end up with a material that fails to meet your needs.Devamını oku

Are you considering building a new home or replacing your existing roofing sheet? Choosing the right type of roofing sheet for your home can be tricky, and it's easy to end up with a material that fails to meet your needs.Devamını oku -

There are many roofing materials available in the market like concrete tiles, terracotta tiles, and ceramic tiles. But recently another type of roofing sheet is getting popular. That is the metal roofing sheets. This gives the house toughness, durability, and a contemporary look. One can easily get a wide range of color choice and it is easy to install. Due to its property of reflecting heat it will keep the house cool and will help in saving energy.Devamını oku

There are many roofing materials available in the market like concrete tiles, terracotta tiles, and ceramic tiles. But recently another type of roofing sheet is getting popular. That is the metal roofing sheets. This gives the house toughness, durability, and a contemporary look. One can easily get a wide range of color choice and it is easy to install. Due to its property of reflecting heat it will keep the house cool and will help in saving energy.Devamını oku -

Every building has a roof. Whether on your home or on the buildings around your home, such as a garage, a garden house or conservatory, or even a storage shed, the roof is an important part of any structure. It protects a building’s interior from the elements but also adds an aesthetic appeal to the building’s top. Investing in the right roof for your home or its surrounding buildings means understanding the options you have to choose from. One of the more important decisions you will make when investing in a roofing project is finding the best roofing sheets.Devamını oku

Every building has a roof. Whether on your home or on the buildings around your home, such as a garage, a garden house or conservatory, or even a storage shed, the roof is an important part of any structure. It protects a building’s interior from the elements but also adds an aesthetic appeal to the building’s top. Investing in the right roof for your home or its surrounding buildings means understanding the options you have to choose from. One of the more important decisions you will make when investing in a roofing project is finding the best roofing sheets.Devamını oku -

Both aspiring and existing property owners should pay attention to one important part of the roof. We are pertaining to what we call roofing sheets. More than the visual value that they add, they are installed for a reason. Different types of roofing sheets shield the actual roof from external elements. When mounted correctly, it helps prevent leaks and potential damages to prolong your roof’s lifespan.Devamını oku

Both aspiring and existing property owners should pay attention to one important part of the roof. We are pertaining to what we call roofing sheets. More than the visual value that they add, they are installed for a reason. Different types of roofing sheets shield the actual roof from external elements. When mounted correctly, it helps prevent leaks and potential damages to prolong your roof’s lifespan.Devamını oku -

Are you considering building a new home or replacing your existing roofing sheet? Choosing the right type of roofing sheet for your home can be tricky, and it's easy to end up with a material that fails to meet your needs. This article will discuss the different types of roofing sheets available and the pros and cons of each material. We'll also provide a step-by-step guide to installing a roofing sheet and essential information you need to consider while making your decision.Devamını oku

Are you considering building a new home or replacing your existing roofing sheet? Choosing the right type of roofing sheet for your home can be tricky, and it's easy to end up with a material that fails to meet your needs. This article will discuss the different types of roofing sheets available and the pros and cons of each material. We'll also provide a step-by-step guide to installing a roofing sheet and essential information you need to consider while making your decision.Devamını oku -

Deciding to replace your building's roof is a significant undertaking, especially when considering factors like age and wear. The cost of roof replacement can be substantial, making it essential to explore cost-effective options without compromising quality. Let's delve into different roofing materials and their cost-effectiveness, bearing in mind the crucial balance between cost and quality.Devamını oku

Deciding to replace your building's roof is a significant undertaking, especially when considering factors like age and wear. The cost of roof replacement can be substantial, making it essential to explore cost-effective options without compromising quality. Let's delve into different roofing materials and their cost-effectiveness, bearing in mind the crucial balance between cost and quality.Devamını oku -

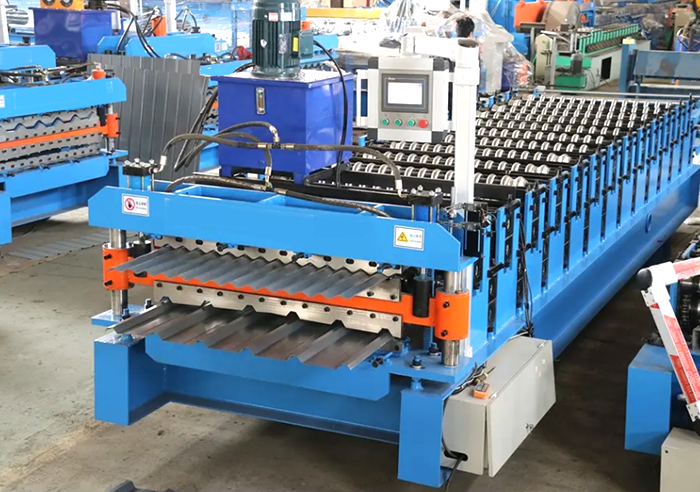

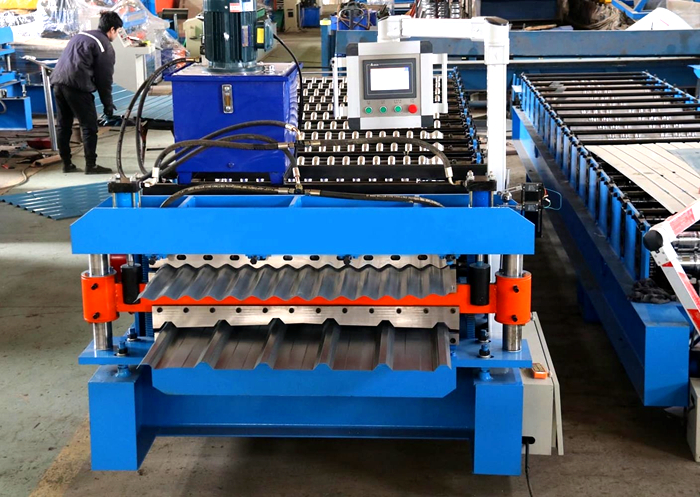

Roll forming machine refers to a complete set of mechanical equipment for parallel processing and rolling of metal billets. Rolling is generally divided into cold rolling and hot rolling. The production capacity of the roll forming machine is an important symbol of the development level of a country’s iron and steel industry. The demand for roll forming machines as construction profiles in China has been increasing year by year, which has a very promising market prospect. With the increase in demand, the product variety and quality requirements of roll forming machines have become increasingly high.Devamını oku

Roll forming machine refers to a complete set of mechanical equipment for parallel processing and rolling of metal billets. Rolling is generally divided into cold rolling and hot rolling. The production capacity of the roll forming machine is an important symbol of the development level of a country’s iron and steel industry. The demand for roll forming machines as construction profiles in China has been increasing year by year, which has a very promising market prospect. With the increase in demand, the product variety and quality requirements of roll forming machines have become increasingly high.Devamını oku -

LONGWAY ROll FOrming MAchine in China passe the 15-year experience on producing Sheet Metal Roll Forming Machine informing industry. this company based on experienced engineers’ ability and performance, each year designed and build more than 100 new metal roll forming systems. Roll forming is a high-volume process of producing profiles by stable cross-section with high dimensional precision. The process parameters play a major role in the quality of the final roll formed product. The optimal configuration of roll forming process parameters, such as the operational line speed, the inter-distance between roll stations, the roll gap, and the diameter of the rolls, can influence the tooling and product designs as well as the product quality.Devamını oku

LONGWAY ROll FOrming MAchine in China passe the 15-year experience on producing Sheet Metal Roll Forming Machine informing industry. this company based on experienced engineers’ ability and performance, each year designed and build more than 100 new metal roll forming systems. Roll forming is a high-volume process of producing profiles by stable cross-section with high dimensional precision. The process parameters play a major role in the quality of the final roll formed product. The optimal configuration of roll forming process parameters, such as the operational line speed, the inter-distance between roll stations, the roll gap, and the diameter of the rolls, can influence the tooling and product designs as well as the product quality.Devamını oku -

Offering roll form tooling maintenance advice is complicated by the fact that each tooling set is designed for a particular profile. At the time a roll forming line is designed, the machine manufacturer considers what will be formed – what kind of shape will be made, the material it will be made from, the yield strength and elongation of the material, the total degrees of bends in the parts, and the tolerances that are to be applied to that part. They then consider whether the part will be precut or post-cut. These are some of the considerations used to select the tooling material.Devamını oku

Offering roll form tooling maintenance advice is complicated by the fact that each tooling set is designed for a particular profile. At the time a roll forming line is designed, the machine manufacturer considers what will be formed – what kind of shape will be made, the material it will be made from, the yield strength and elongation of the material, the total degrees of bends in the parts, and the tolerances that are to be applied to that part. They then consider whether the part will be precut or post-cut. These are some of the considerations used to select the tooling material.Devamını oku -

While there is no catch-all roll forming solution for every business, there are some elements of the roll forming process that ring true across operations. Regardless of your size, your industry, and even your end product, roll forming machinery is designed to add efficiency, quality, and ultimately profits to your metal forming processes. The requirements necessary to maintain and operate a roll forming system can be loosely defined depending on your shop's specific needs. In this post, we'll discuss some of the variables that determine roll forming line operation and setup across metal forming industries.Devamını oku

While there is no catch-all roll forming solution for every business, there are some elements of the roll forming process that ring true across operations. Regardless of your size, your industry, and even your end product, roll forming machinery is designed to add efficiency, quality, and ultimately profits to your metal forming processes. The requirements necessary to maintain and operate a roll forming system can be loosely defined depending on your shop's specific needs. In this post, we'll discuss some of the variables that determine roll forming line operation and setup across metal forming industries.Devamını oku -

The Roll Forming Machine Working Principle is the process of forming profiles of different cross-sectional shapes by passing a steel plate of a certain size through several sets of up and down pressed rolls. The process characteristics of roll forming determine the various advantages of roll forming, making roll forming machines widely used in profile production. The process characteristics determine the low investment in roll-forming, the rapid entry into production, the high output and the possibility of a highly automated production line. Moreover, the equipment has high stability, high production efficiency and low defective rate. The equipment is easy to maintain and other characteristics.Devamını oku

The Roll Forming Machine Working Principle is the process of forming profiles of different cross-sectional shapes by passing a steel plate of a certain size through several sets of up and down pressed rolls. The process characteristics of roll forming determine the various advantages of roll forming, making roll forming machines widely used in profile production. The process characteristics determine the low investment in roll-forming, the rapid entry into production, the high output and the possibility of a highly automated production line. Moreover, the equipment has high stability, high production efficiency and low defective rate. The equipment is easy to maintain and other characteristics.Devamını oku -

Last time around we took a closer look at problems in the roll forming process and found that work material generally is not the culprit. If material is ruled out, what can the problem be? No changes have been made, and the operator and setup people claim that they have done nothing different. Hmm ...Devamını oku

Last time around we took a closer look at problems in the roll forming process and found that work material generally is not the culprit. If material is ruled out, what can the problem be? No changes have been made, and the operator and setup people claim that they have done nothing different. Hmm ...Devamını oku