standing seam metal roof roll former factories

Understanding Standing Seam Metal Roof Roll Formers A Comprehensive Overview

Standing seam metal roofs have gained immense popularity in recent years due to their durability, energy efficiency, and aesthetic appeal. In the heart of this growing industry lie standing seam metal roof roll former factories. These facilities are crucial in manufacturing high-quality metal roofing panels that meet the increasing demands of architects, builders, and homeowners alike.

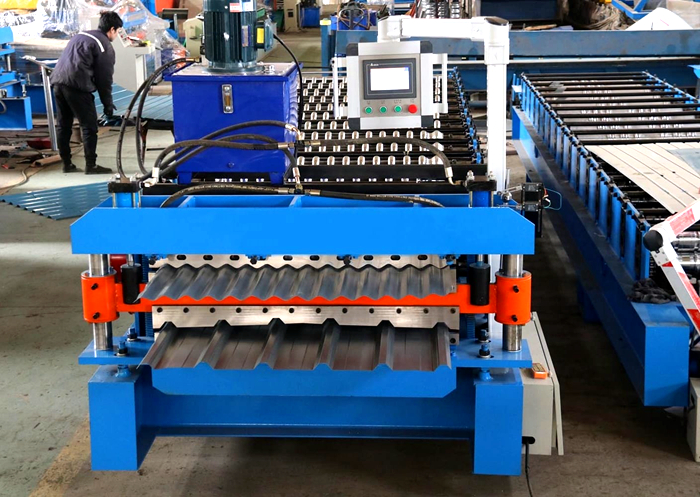

At its core, a roll former is a piece of machinery that shapes metal sheets into specific profiles, which are then used in construction. The unique interlocking design of standing seam systems not only enhances their visual appeal but also offers significant advantages in terms of watertightness and expansion capabilities. This is where the expertise of roll former factories comes into play. They utilize high-precision machinery to create different styles and profiles of standing seam roofing panels, catering to various architectural designs and building requirements.

The Machinery and Technology Behind Roll Formers

Roll forming machines in these factories undergo several stages during the manufacturing process. Initially, a flat sheet of metal, usually galvanized steel or aluminum, is fed into the machine. As the metal passes through a series of rollers, it gradually bends and forms into the desired standing seam profile. Advanced roll forming technology ensures consistent dimensions, which is crucial for effective installation and long-term performance.

Modern roll formers often incorporate computer numerical control (CNC) systems that enhance precision and can be programmed for various profiles without the need for manual adjustments. Such technology not only increases efficiency but also reduces waste—a significant benefit in today’s cost-sensitive and environmentally conscious market.

Quality Control in Manufacturing

standing seam metal roof roll former factories

Ensuring high-quality output is paramount in roll former factories. Rigorous quality control measures are implemented throughout the manufacturing process. This includes checking the thickness and coating of the metal sheets, ensuring that the dimensions of the formed profiles adhere to strict standards, and conducting tests to assess the strength and watertightness of the finished products. Quality assurance not only helps in maintaining customer satisfaction but also establishes the brand’s reputation in a highly competitive market.

Customization and Versatility

One of the standout features of standing seam metal roof roll former factories is their ability to produce customized products. Architects and builders often have specific requirements based on the design of the building and the geographical location. Roll former factories can adapt to these needs by offering various panel widths, seam heights, and even unique finishes. This flexibility makes standing seam metal roofs a popular choice for both residential and commercial projects.

The Role of Innovation

The roofing industry is continually evolving, and roll former manufacturers are at the forefront of innovation. Many factories are investing in research and development to enhance the capabilities of their machinery, explore new materials, and improve the overall efficiency of the production process. This commitment to innovation not only allows for the introduction of new products but also enhances the sustainability of the manufacturing processes by minimizing waste and energy consumption.

Conclusion

Standing seam metal roof roll former factories play a vital role in the construction industry by providing high-quality, customizable roofing solutions. With state-of-the-art technology, stringent quality control measures, and a focus on innovation, these factories ensure that builders and homeowners have access to durable and aesthetically pleasing roofing options. As the demand for energy-efficient and sustainable building materials continues to rise, the importance of these specialized manufacturing facilities will only increase, solidifying their position as key players in the roofing industry.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025