Standing Seam Profiling Machine Factory - High-Quality Metal Roofing Solutions

Understanding Standing Seam Profiling Machines Advancements and Importance in Metal Roofing Fabrication

Standing seam roofs have gained significant popularity in the construction and architecture sectors due to their durability, aesthetic appeal, and energy efficiency. To efficiently produce the standing seam panels required for these roofs, specialized equipment known as standing seam profiling machines has been developed. These machines play a pivotal role in the metal roofing industry, ensuring precision and consistency in panel fabrication.

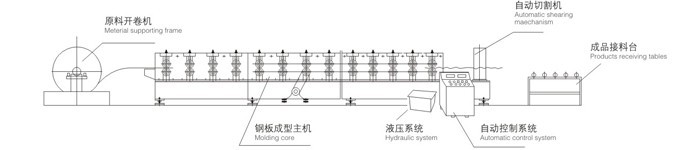

A standing seam profiling machine is designed to fabricate metal sheets into standing seam panels that interlock on the roof. The process starts with large coils of metal, typically aluminum or steel, which undergo a series of transformations through rollers in the machine. These rollers gradually shape the metal to the desired profile and form the distinct raised seams that characterize standing seam roofs.

One of the primary advantages of using a standing seam profiling machine is the enhancement of efficiency in production. With automated systems, these machines can produce continuous lengths of material, minimizing waste and reducing the need for extensive manual labor. Additionally, the machines often come equipped with advanced controls that allow for precise adjustments. This level of precision ensures that the panels not only fit perfectly but also maintain the aesthetic integrity required by modern architectural standards.

standing seam profiling machine factory

Moreover, the advances in technology have significantly improved the capabilities of these machines. Today’s standing seam profiling machines feature digital interfacing systems, allowing operators to program various profiles easily. This versatility is essential for manufacturers looking to produce multiple types of panels for different applications, from residential roofing to commercial structures.

Quality control is another critical consideration in the operation of standing seam profiling machines. Modern equipment incorporates inspection systems that monitor the dimensions and integrity of each panel produced. By ensuring that each panel meets stringent standards, manufacturers can assure their clients of the durability and reliability of the roofing solution.

Furthermore, the importance of standing seam profiling machines extends beyond production efficiency and quality. Given the growing emphasis on sustainable building practices, manufacturers are increasingly focused on producing roofing systems that enhance energy performance. Standing seam roofs can accommodate insulation and reflective coatings, contributing to improved energy efficiency in buildings. Profiling machines that facilitate this aspect of roofing will only increase in importance as the industry moves towards greener solutions.

In conclusion, standing seam profiling machines are vital for the production of modern roofing solutions. Their role in efficiency, precision, versatility, and quality control cannot be overstated. As technologies evolve, these machines will continue to be at the forefront of advancements in the metal roofing industry, meeting the diverse needs of architects, builders, and homeowners alike.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025