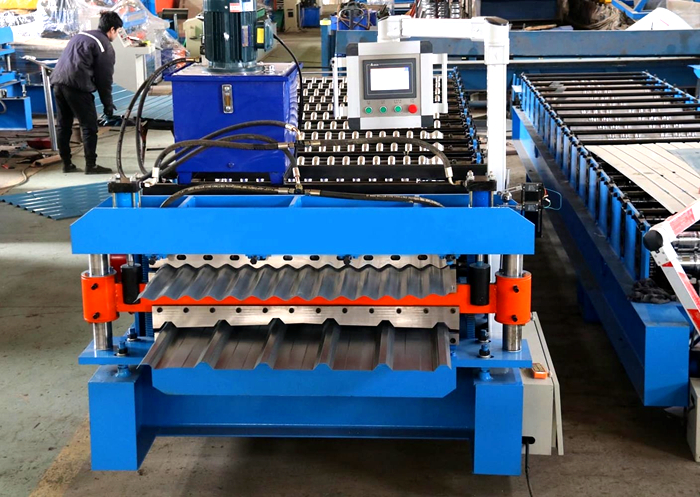

shutter roll forming machine

Shutter Roll Forming Machines Revolutionizing the Industry

In today's fast-paced manufacturing landscape, efficiency and precision are paramount. One of the innovations that have significantly contributed to enhanced production capabilities is the shutter roll forming machine. These machines are essential in the manufacturing of various types of roll-up shutters, which are widely used in commercial and residential applications. This article delves into the features, benefits, and applications of shutter roll forming machines, highlighting their importance in modern construction and security solutions.

What is a Shutter Roll Forming Machine?

A shutter roll forming machine is a specialized piece of equipment designed to create consistently shaped metal profiles for rolling shutters. These machines work by feeding a metal coil into a series of rollers that gradually bend and shape the material into the desired profile. The finished products are typically made from high-quality steel or aluminum, ensuring durability, strength, and resistance to environmental factors.

Key Features

Shutter roll forming machines come equipped with several key features that enhance their functionality

1. High Precision The roller configuration is designed to ensure that the finished product meets exact specifications. High-precision components contribute to the accuracy of the dimensions, minimizing waste and rework.

2. Adjustable Speed These machines can operate at varying speeds, allowing manufacturers to adjust production rates according to demand. This flexibility is crucial in optimizing production efficiency and meeting tight deadlines.

3. User-Friendly Controls Modern shutter roll forming machines are equipped with advanced control systems that allow operators to program specific manufacturing parameters easily. This feature simplifies operation and reduces the learning curve for new staff.

4. Versatile Design Many machines offer the capability to produce multiple shutter designs, from traditional styles to more contemporary options. This versatility enables manufacturers to cater to a broader market.

Benefits of Using Shutter Roll Forming Machines

shutter roll forming machine

Investing in a shutter roll forming machine presents several advantages for manufacturers

- Cost-Effectiveness The efficiency of these machines reduces labor costs and minimizes production time. The automated processes also lead to lower operational expenses over time.

- High-Quality Output With precision engineering, shutter roll forming machines produce high-quality finished products that meet industry standards. This quality assurance helps in building a reputable brand.

- Reduced Waste The precise shaping and cutting of materials lead to less waste during production. This not only makes the process more economical but also aligns with sustainable manufacturing practices.

- Improved Safety With automated systems and streamlined processes, the risk of workplace accidents is significantly reduced. Operators can manage the machines more safely, leading to a more secure working environment.

Applications

Shutter roll forming machines are widely used across various sectors due to their versatility

- Commercial Buildings They are commonly employed in constructing storefronts, warehouses, and parking garages where security and ease of access are critical. Roll-up shutters provide an effective barrier against theft while allowing for convenient entry.

- Residential Use Homeowners are increasingly opting for roll-up shutters for garages, balconies, and windows. These shutters enhance security and also serve as effective insulation against temperature extremes.

- Industrial Settings Factories and manufacturing plants utilize these shutters to secure equipment and facilities, protecting valuable assets and ensuring safety compliance.

Conclusion

Shutter roll forming machines are an integral part of modern manufacturing, offering significant advantages in production efficiency, cost-effectiveness, and quality. As the demand for roll-up shutters continues to rise in both commercial and residential markets, these machines will play a pivotal role in shaping the future of construction and security solutions. By investing in advanced shutter roll forming technology, manufacturers can ensure they remain competitive in an ever-evolving industry while catering to the growing needs of their customers. Whether it's ensuring a business's safety or enhancing a home's aesthetic appeal, shutter roll forming machines are undoubtedly redefining how we approach building security and efficiency.

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025