Jan . 23, 2025 00:52

Back to list

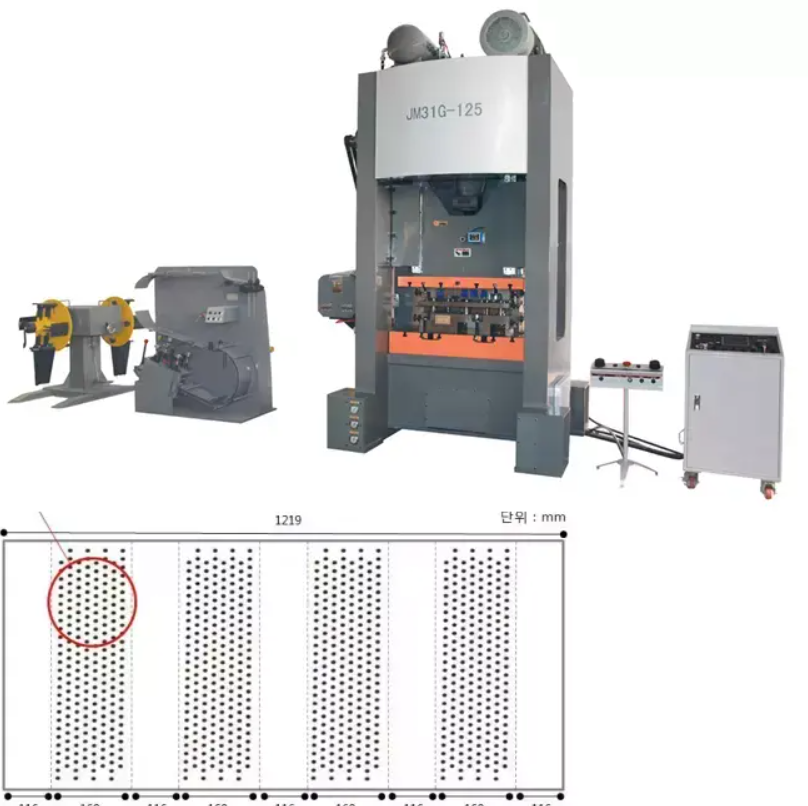

shutter patti making machine

The evolution of industrial machinery often marks a transformative impact on production efficiencies and product quality. Shutter patti making machines have become instrumental in revolutionizing the metal forming and construction industries. As a seasoned SEO specialist, I delve into the intricacies of this equipment to uncover its value proposition and explore why businesses are increasingly integrating these machines into their operations.

Expertise in operating shutter patti making machines is crucial for maximizing their potential. Companies should invest in thorough training for operators to ensure they can fully leverage the machine's capabilities. Proficiency in operating these machines safeguards against production delays due to user error and enhances overall productivity. The importance of trustworthiness when investing in a shutter patti making machine cannot be overemphasized. Partnering with reputable manufacturers who provide not only superior machinery but also after-sales support and service ensures a long-term operational advantage. Companies should prioritize vendors with verified track records, stellar customer reviews, and robust warranties to safeguard their investment. Shutter patti making machines are also evolving to become more environmentally conscious. The latest models incorporate energy-efficient technologies that reduce electricity consumption, aligning with global sustainability initiatives. Companies can thus appeal to environmentally aware consumers who value eco-friendly production practices, thereby enhancing their brand reputation while minimizing their carbon footprint. The integration of smart technology into shutter patti making machines is another trend that cannot be overlooked. Many modern machines are equipped with IoT functionalities and data analytics capabilities. These innovations enable real-time monitoring and diagnostics, allowing operators to anticipate and address potential issues before they culminate into costly downtime. Such technological advances make the machines more intuitive and user-friendly, broadening their appeal and reducing the learning curve for operational proficiency. Concluding, a shutter patti making machine is a robust asset for manufacturers in the metal forming and construction industries. Its ability to produce high-quality, consistent, and customizable products at an accelerated pace offers a distinct competitive edge. By selecting reputable machinery and investing in professional training, companies can guarantee enhanced operational efficiency, cost-effectiveness, and customer satisfaction. Moreover, through embracing sustainable practices and advanced technologies, manufacturers not only future-proof their operations but also contribute positively to the industry's growth trajectory.

Expertise in operating shutter patti making machines is crucial for maximizing their potential. Companies should invest in thorough training for operators to ensure they can fully leverage the machine's capabilities. Proficiency in operating these machines safeguards against production delays due to user error and enhances overall productivity. The importance of trustworthiness when investing in a shutter patti making machine cannot be overemphasized. Partnering with reputable manufacturers who provide not only superior machinery but also after-sales support and service ensures a long-term operational advantage. Companies should prioritize vendors with verified track records, stellar customer reviews, and robust warranties to safeguard their investment. Shutter patti making machines are also evolving to become more environmentally conscious. The latest models incorporate energy-efficient technologies that reduce electricity consumption, aligning with global sustainability initiatives. Companies can thus appeal to environmentally aware consumers who value eco-friendly production practices, thereby enhancing their brand reputation while minimizing their carbon footprint. The integration of smart technology into shutter patti making machines is another trend that cannot be overlooked. Many modern machines are equipped with IoT functionalities and data analytics capabilities. These innovations enable real-time monitoring and diagnostics, allowing operators to anticipate and address potential issues before they culminate into costly downtime. Such technological advances make the machines more intuitive and user-friendly, broadening their appeal and reducing the learning curve for operational proficiency. Concluding, a shutter patti making machine is a robust asset for manufacturers in the metal forming and construction industries. Its ability to produce high-quality, consistent, and customizable products at an accelerated pace offers a distinct competitive edge. By selecting reputable machinery and investing in professional training, companies can guarantee enhanced operational efficiency, cost-effectiveness, and customer satisfaction. Moreover, through embracing sustainable practices and advanced technologies, manufacturers not only future-proof their operations but also contribute positively to the industry's growth trajectory.

Latest news

-

The Role of Hydraulic Systems in Sheet Metal SlittersNewsAug.23, 2025

-

Customization Options in Metal Deck Roll Forming MachinesNewsAug.23, 2025

-

Safety Tips When Using a Gutter Making MachineNewsAug.23, 2025

-

Key Components of a C Purlin Machine ExplainedNewsAug.23, 2025

-

Maintenance Tips for a Steel Angle Roll Forming MachineNewsAug.23, 2025

-

Portable Metal Roofing Machine Applications in Remote ConstructionNewsAug.23, 2025

-

Roof Panel MachineNewsAug.18, 2025

Related Products