Cost of Roofing Roll Forming Machines for Efficient Production Solutions

Understanding the Price Factors of Roofing Roll Forming Machines

Roofing roll forming machines are essential pieces of equipment in the metalworking industry, particularly for producing roofing sheets and panels. The price of these machines can vary significantly based on several factors, which potential buyers need to understand to make an informed decision.

1. Machine Specifications The specifications of the roofing roll forming machine play a crucial role in determining its price. Machines with higher capacity, greater speed, and advanced features such as automation and digital control systems tend to be more expensive. For instance, a machine capable of producing thicker sheets or multiple profiles in a single run will generally cost more than a basic model designed for thinner materials.

2. Quality of Materials The construction materials used in the manufacturing of the roll forming machine also impact its cost. Higher-quality steel and components ensure durability and longevity, which can justify a higher price. Moreover, machines that come with protective coatings to resist rust and wear can offer better investment value over time.

3. Brand Reputation Brand reputation plays a significant role in pricing. Established manufacturers with a strong track record of reliability and performance may charge more due to consumer trust and guaranteed quality. Conversely, lesser-known brands might offer lower prices but could come with risks related to quality and after-sales service.

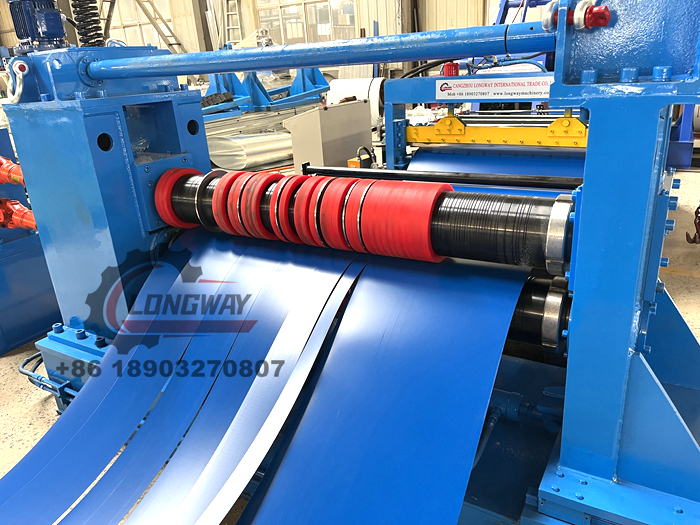

roofing roll forming machine price

4. Customization Options Many buyers require customized solutions tailored to their specific production needs. Customization can significantly increase the price of the machinery, but it can lead to increased efficiency and productivity, making it a worthwhile investment for businesses with high production demands.

5. Regional Factors The location of the manufacturer also influences the price. Machines produced in countries with higher labor and material costs may be priced higher than those manufactured in regions with lower production costs. Additionally, shipping and import duties can add to the final cost for international buyers.

6. Technological Advancements As technology advances, newer models of roofing roll forming machines come equipped with smart features such as PLC control, remote monitoring, and interface systems. These innovations generally demand higher upfront investments but can lead to lower operating costs and increased output efficiency in the long run.

Conclusion In conclusion, the price of roofing roll forming machines is influenced by various factors including specifications, material quality, brand reputation, customization options, regional costs, and technological advances. When considering a purchase, it's crucial for buyers to evaluate these factors against their production needs and budget to ensure they choose the right machine for their operations. Understanding these elements will lead to a more informed purchase that balances cost with performance, ultimately contributing to the success of their roofing projects.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025