roll former for parantes y rieles manufacturers

The Roll Former Revolutionizing the Production of Parantes and Rieles

In the realm of manufacturing, efficiency and precision are paramount. One technology that has significantly enhanced these aspects, particularly in the production of parantes (vertical supports) and rieles (rails), is the roll former. This innovative machinery has transformed the way manufacturers produce metal components, allowing for high precision, reduced waste, and increased output.

Understanding Roll Forming

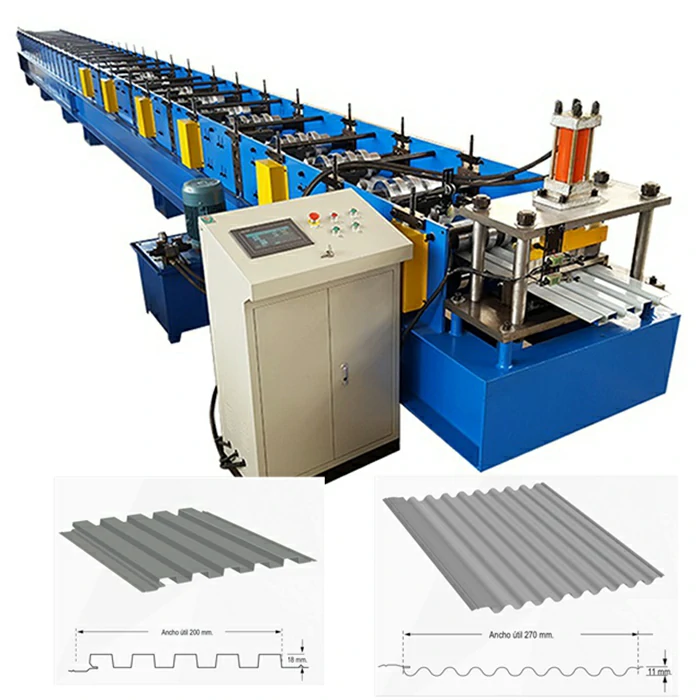

Roll forming is a continuous bending operation that transforms a long strip of metal into a specific cross-sectional profile. This process involves passing the metal sheet through a series of rollers, each designed to incrementally shape the material until the desired final profile is achieved. The beauty of roll forming lies in its ability to produce long lengths of uniform sections, making it particularly suitable for components like parantes and rieles that require consistent dimensions over significant spans.

Advantages of Using Roll Formers

1. High Production Efficiency One of the primary benefits of roll forming is its speed. Once the initial setup is complete, roll forming can produce large quantities of components in a fraction of the time it would take using traditional methods. This efficiency is particularly advantageous for manufacturers that require bulk production, allowing them to meet customer demands promptly.

2. Material Utilization Traditional manufacturing processes often generate substantial waste, particularly during the cutting phase. In contrast, roll forming utilizes the entire strip of metal with minimal scrap, optimizing material usage. This cost-saving aspect not only benefits manufacturers but also supports sustainability initiatives by reducing the environmental impact associated with production waste.

3. Customization and Versatility Roll formers can be easily reconfigured to produce a vast array of shapes and profiles. This versatility is crucial for manufacturers producing specialized parantes and rieles for various applications, including construction, transportation, and industrial purposes. The ability to switch between different profiles quickly and without major downtime means that manufacturers can adapt swiftly to market demands.

roll former for parantes y rieles manufacturers

4. Superior Strength and Durability The roll forming process increases the strength of the metal due to the continuous bending and controlled shaping. This enhancement results in parantes and rieles that are not only precise in dimensions but also robust enough to withstand heavy loads and harsh conditions. Consequently, the end products have a longer lifespan, reducing the need for frequent replacements.

5. Reduced Labor Costs Automation is a central theme in modern manufacturing. Roll formers can be integrated with automated systems, reducing the need for manual labor. This automation not only cuts labor costs but also minimizes human error, ensuring that all produced components meet strict quality standards.

Applications of Parantes and Rieles

The applications of parantes and rieles are wide-ranging. In construction, parantes serve as essential vertical supports that ensure the structural integrity of buildings and frameworks. Similarly, rieles are crucial in providing guidance for rolling stock, particularly in railway systems where they form the bedrock of the infrastructure.

In industrial settings, these components are also used in conveyor systems, shelving, and storage solutions, showcasing their versatility and importance across various sectors. With the growing demand for efficient construction methods and robust infrastructure, the need for high-quality parantes and rieles produced through innovative processes like roll forming will only continue to rise.

Conclusion

The roll former represents a paradigm shift in the way parantes and rieles are manufactured, marrying efficiency with precision. As manufacturers lean towards automation and sustainability, the advantages of roll forming become increasingly clear. With its high production rates, minimal waste, and adaptability to different applications, roll forming is not just a manufacturing technique—it's an essential part of modern industrial practices. As the industry continues to evolve, integrating advanced technologies like roll forming will be key for manufacturers aiming to stay competitive and meet the changing demands of the market. The future of manufacturing in the realm of parantes and rieles looks bright, driven by the capabilities of roll forming technologies.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025