Top Manufacturers of Rack and Roll Forming Machines for Efficient Production

Rack and Roll Forming Machine Companies An Overview

The manufacturing industry has been experiencing remarkable advancements over the years, predominantly due to the integration of cutting-edge technologies and the rising demand for efficient production methods. Among the most significant innovations is the development of rack and roll forming machines. These machines revolutionize the way manufacturers create various types of frames and structures, particularly in the storage and transport sectors. This article will explore the features, benefits, and leading companies in the rack and roll forming machine sector.

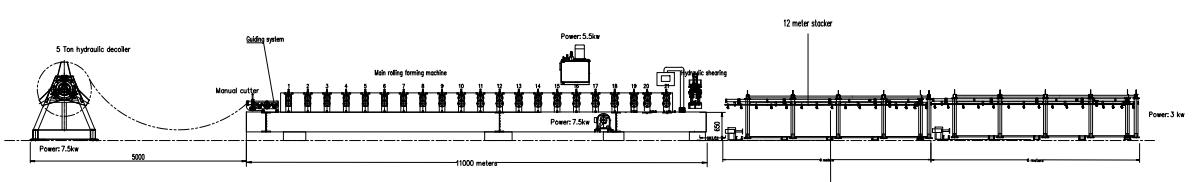

Rack and roll forming machines are specialized equipment designed to produce rack components using a continuous metal forming process. This innovative machinery shapes metal strips into intricate profiles that are essential in constructing shelving units, racking systems, and other storage solutions. The machines utilize a series of rollers that progressively form the metal into its desired shape, ensuring high precision and consistent quality.

One of the key benefits of using rack and roll forming machines is their efficiency. These machines are capable of producing large volumes of components in a fraction of the time it would take to manufacture them through traditional methods. By allowing manufacturers to streamline production processes, the machines significantly reduce labor costs and minimize material waste, leading to more sustainable manufacturing practices. Furthermore, advanced technologies embedded within these machines, such as computer numerically controlled (CNC) systems, enhance accuracy and allow for easy adjustments, catering to diverse production needs.

The global market for rack and roll forming machines has witnessed substantial growth, driven by the rising demand for customized racking solutions across various industries, including logistics, retail, and warehousing. As businesses increasingly seek efficient storage systems to optimize space utilization, the need for high-quality rack and roll forming machines becomes even more pronounced.

rack roll forming machine companies

Among the leading companies in the rack and roll forming machine industry, several stand out due to their innovation, market presence, and commitment to quality. One such company is A.B. Hydra, known for its state-of-the-art machinery that combines durability with advanced technology. Their machines feature user-friendly interfaces and customization options, making them ideal for businesses looking to adapt to rapidly evolving market demands.

Another notable player is Formtek, which offers a comprehensive range of roll forming solutions. Their customizable machines cater to various applications, allowing clients to choose configurations tailored to their specific needs. Formtek’s emphasis on engineering excellence ensures that their customers receive robust machines that can withstand rigorous operational demands.

Pioneer Equipment is also renowned in the industry for its production of high-performance rack and roll forming machines. With a focus on innovation, Pioneer Equipment invests heavily in research and development, constantly enhancing its products to meet emerging industry standards. Their commitment to customer satisfaction is evident in their after-sales support and training services.

In addition to these key players, numerous other companies contribute to the vibrant ecosystem of rack and roll forming machines. This competition fosters continual improvement and innovation, pushing the boundaries of what these machines can achieve.

In conclusion, rack and roll forming machines represent a crucial development in the manufacturing sector, offering unparalleled efficiency, versatility, and precision. The dedication of companies like A.B. Hydra, Formtek, and Pioneer Equipment not only enhances production capabilities but also underscores the importance of innovation in meeting modern industrial challenges. As the demand for effective storage solutions continues to grow, the role of rack and roll forming machines will undoubtedly become even more integral to the landscape of manufacturing.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025