rack roll forming machine

Understanding Rack Roll Forming Machines A Comprehensive Overview

In the modern industrial landscape, efficiency and precision are paramount. Among the various processes that enhance production capabilities, roll forming stands out as a highly effective method for producing metal components. The rack roll forming machine, in particular, has gained significant attention for its ability to create durable and versatile products used in a wide array of applications, particularly in the shelving and racking industries.

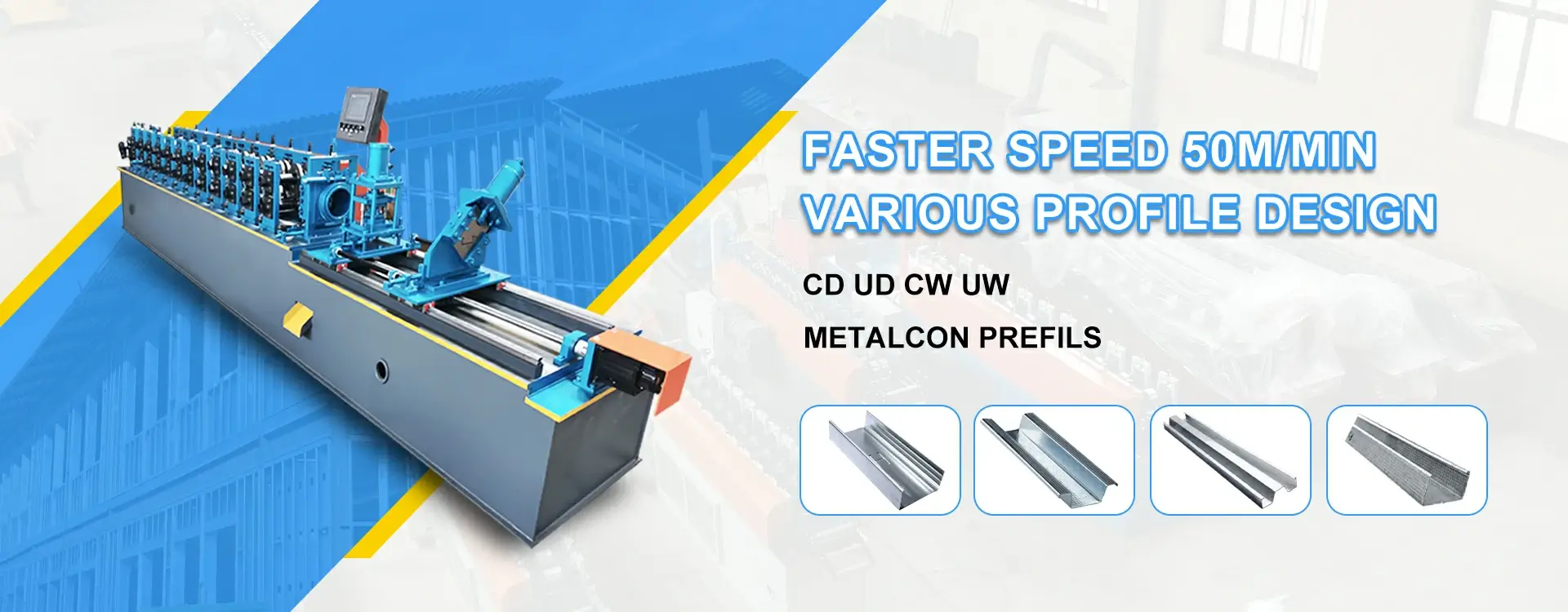

What is a Rack Roll Forming Machine?

A rack roll forming machine is a specialized piece of equipment designed to shape metal sheets into specific profiles required for constructing racks and shelving units. This machine utilizes a continuous bending operation, where a long strip of metal is passed through a series of rollers that progressively form it into the desired shape. The result is a high-quality, consistent product that meets stringent industry standards.

The Process of Roll Forming

The roll forming process involves several key steps. First, a flat metal sheet, typically made of steel or aluminum, is fed into the machine. The rollers, which are strategically positioned, apply pressure to the metal as it moves through, gradually bending and shaping it into the desired profile. The precision of this process is a major advantage since it allows for the uniform production of components that can be easily assembled into final products like storage racks and shelves.

Once the desired shape is achieved, the formed metal can be cut to length, punched for additional features, or otherwise processed according to the specifications of the final assembly. This versatility is incredibly beneficial for manufacturers who require custom solutions for their shelving and storage needs.

Advantages of Rack Roll Forming Machines

rack roll forming machine

1. High Efficiency Roll forming machines can produce long lengths of formed metal with minimal wasted material. Their continuous operation means that they can achieve high output rates, making them particularly advantageous for large-scale production.

2. Customization The ability to easily change the die sets and adjust the rollers allows manufacturers to create customized solutions for different applications. This adaptability is essential in a market that often demands unique specifications.

3. Durability Products formed through this method tend to exhibit superior durability and strength, making them suitable for even the most demanding environments. This is particularly important for rack systems that need to support significant weights over time.

4. Cost-Effectiveness While the initial investment in a rack roll forming machine can be substantial, the long-term savings in material usage and labor costs often offset this expense. The efficiency and speed of the process translate into cost savings that many manufacturers find appealing.

Applications in Industry

Rack roll forming machines are widely used in various industries, including retail, warehousing, and manufacturing. They are instrumental in creating various types of racks, from simple shelving units to complex storage systems designed for heavy-duty applications. Additionally, the ease of integration with automation systems means that these machines can be a part of a larger, more streamlined production line, further enhancing their utility.

Conclusion

In an era where efficiency and customization are critical to business success, rack roll forming machines offer a valuable solution for manufacturers seeking to enhance their production capabilities. By providing a method to create durable and versatile storage solutions, these machines play a vital role in meeting the growing demands of various sectors. As technology continues to advance, the capabilities and applications of rack roll forming machines will likely expand, further solidifying their place in modern manufacturing processes.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025