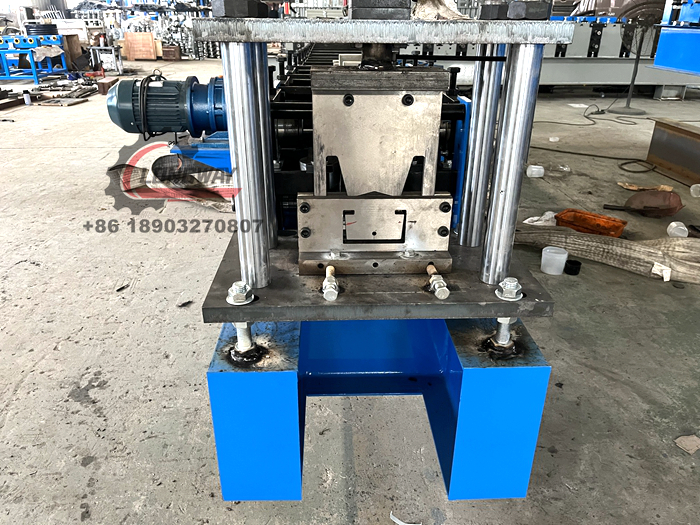

mobile roll forming machine

Mobile Roll Forming Machine Revolutionizing the Metal Fabrication Industry

In the ever-evolving landscape of metal fabrication, the introduction of mobile roll forming machines has marked a significant milestone. These innovative machines have transformed the way metal components are manufactured, reducing production time and increasing efficiency. With their portability and versatility, mobile roll forming machines are becoming indispensable tools for various industries, including construction, automotive, and manufacturing.

Mobile roll forming machines are designed to produce continuous profiles from coils of metal, typically steel or aluminum. Unlike traditional stationary roll forming machines, mobile variants can be easily transported to different job sites. This mobility offers businesses unprecedented flexibility, allowing them to meet the demands of their projects without the delays associated with transporting materials to a fixed location. As a result, the risk of damage and waste during transportation is significantly minimized, leading to cost savings.

One of the standout features of mobile roll forming machines is their ability to produce a wide range of profiles. From roof panels and wall cladding to custom metal trims, these machines can cater to various specifications and requirements. This adaptability makes them ideal for projects of all scales, whether it be residential buildings, commercial spaces, or large industrial complexes. Additionally, with the rise of prefabrication in construction, mobile roll forming machines play a crucial role in producing components in advance, thereby expediting the construction process.

mobile roll forming machine

The technological advancements integrated into mobile roll forming machines further enhance their efficiency. Many models are equipped with advanced control systems that allow for precise adjustments to be made easily, ensuring consistent quality in the finished products. Moreover, with the use of automation and robotic systems, the production process can be streamlined, reducing labor costs and minimizing human error. This shift towards automation not only increases productivity but also allows skilled workers to focus on more complex tasks that require their expertise.

Furthermore, the environmental impact of mobile roll forming machines is relatively low compared to traditional methods. With the ability to generate less waste and improve energy efficiency, these machines align with the growing emphasis on sustainable manufacturing practices. By using materials more effectively and reducing excess, businesses can contribute to a greener future while simultaneously enhancing their bottom line.

In conclusion, mobile roll forming machines represent a significant advancement in metal fabrication technology. Their mobility, adaptability, and efficient production capabilities provide unparalleled benefits to a variety of industries. As the demand for speed and precision continues to rise, the mobile roll forming machine is set to become a staple in manufacturing processes worldwide. By embracing this innovative solution, businesses can not only improve operational efficiency but also ensure they remain competitive in an increasingly dynamic market. As technology continues to develop, the future of mobile roll forming machines promises even greater possibilities for efficiency and sustainability in metal fabrication.

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025