Top Manufacturers of Metal Roof Forming Machines for Quality Roofing Solutions

Exploring the World of Metal Roof Forming Machine Manufacturers

In the ever-evolving construction and manufacturing industries, the demand for efficient and durable roofing solutions has driven technological advancements, particularly in metal roofing systems. At the forefront of this innovation are metal roof forming machines, specialized equipment that are essential for producing high-quality metal roofing sheets. This article explores the role of metal roof forming machine manufacturers, the technology behind these machines, and the benefits they offer to the roofing industry.

The Role of Metal Roof Forming Machine Manufacturers

Metal roof forming machine manufacturers are responsible for designing and producing machines that can transform raw metal coils into finished roofing panels. These machines are engineered to cater to diverse architectural styles and building requirements. Manufacturers often specialize in particular types of machines, such as roll forming machines, single-layer machines, or double-layer machines, depending on their niche market.

The manufacturing process typically involves several steps, including designing the machine's specifications, sourcing raw materials, fabricating components, and assembling the final product. Additionally, many manufacturers offer customization options to meet specific client needs, providing tailored solutions that enhance production efficiency and product quality.

Technology Behind Metal Roof Forming Machines

The technology employed in metal roof forming machines has seen significant advancements over the years. Modern machines utilize Computer Numerical Control (CNC) technology, which allows for precise automation of the forming process. With CNC, manufacturers can maintain consistent quality across large production runs, ensuring that each roofing panel conforms to the desired specifications.

Moreover, some manufacturers integrate advanced software that enables real-time monitoring and adjustments during the production process. This feature not only enhances efficiency but also significantly reduces material waste, contributing to a more sustainable manufacturing process.

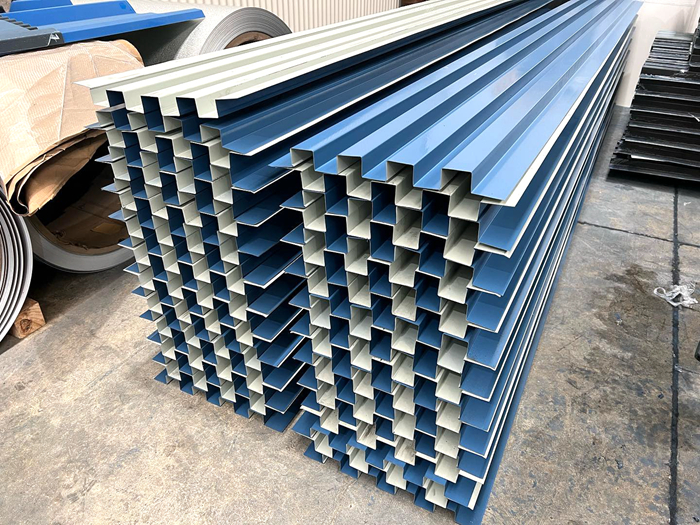

metal roof forming machine manufacturers

Machines often come equipped with multiple features, including pre-cutting, post-cutting, and various forming profiles, allowing manufacturers to produce a range of roofing styles, from corrugated sheets to standing seam roofs. These capabilities facilitate a quick response to market demands, empowering builders and construction teams to complete projects on time.

Benefits of Metal Roof Forming Machines

The advantages of using metal roofing solutions produced by metal roof forming machines are manifold. One of the most significant benefits is durability. Metal roofs are generally more resilient than traditional roofing materials, offering excellent resistance to harsh weather conditions, including rain, snow, and extreme temperatures. This durability translates to lower maintenance costs and a longer lifespan, making metal roofs a wise investment for building owners.

Furthermore, metal roofs are lightweight, which reduces the structural load on buildings and allows for easier handling during installation. Metal roof forming machines create panels that fit together seamlessly, minimizing the risk of leaks and ensuring optimal insulation. Additionally, the energy efficiency of metal roofs can lead to reduced heating and cooling costs, making them an environmentally friendly choice.

From an aesthetic perspective, metal roofs offer a variety of styles and colors, allowing homeowners and builders to achieve the desired look without compromising on functionality. With options to mimic traditional materials such as shingles or tiles, metal roofs can enhance the overall appeal of a structure.

Conclusion

As the demand for metal roofing systems continues to grow, metal roof forming machine manufacturers are positioned as pivotal players in the construction industry. Their innovations not only contribute to the quality and durability of roofing solutions but also promote sustainability and efficiency in building practices. By investing in advanced metal roof forming machines, manufacturers ensure that they meet the evolving needs of builders and consumers alike, solidifying the role of metal roofing as a leading choice in modern construction. As technology continues to progress, there's no doubt that the future of metal roofing machinery will bring even more exciting developments to the industry.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025