Manufacturer of High-Quality Shutter Strip Production Equipment for Efficient Manufacturing

The Role of Shutter Strip Making Machine Manufacturers in Modern Manufacturing

In today’s rapidly evolving manufacturing landscape, the demand for efficient and high-quality production processes is greater than ever. Among the various niche markets, the production of shutter strips—used in various applications from security shutters to garage doors—has gained significant traction. The effectiveness of this production largely depends on the machines utilized, particularly shutter strip making machines, which are designed to automate and streamline the manufacturing process. This article explores the role of shutter strip making machine manufacturers, their technology, and their impact on the industry.

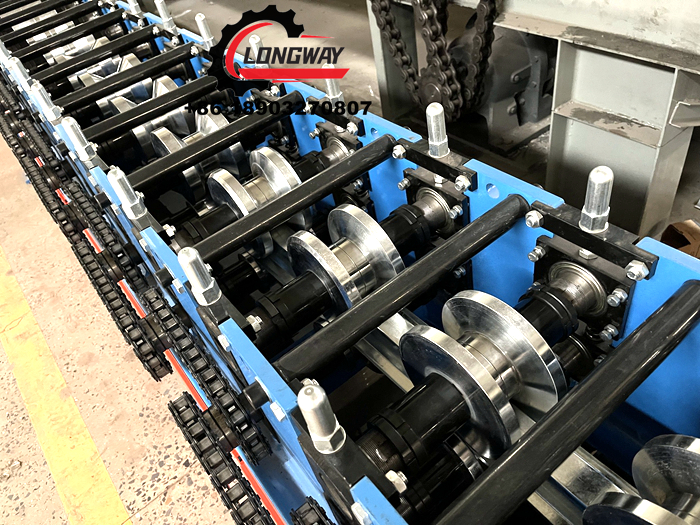

Understanding Shutter Strip Making Machines

Shutter strip making machines are specialized equipment designed to produce strips that form the slats of shutters. These machines can handle several materials, including aluminum, PVC, and steel, allowing for versatility in product offerings. They typically incorporate advanced technology, enabling manufacturers to produce strips that meet specific dimensions, thicknesses, and finishes, aligning with various customer requirements.

Technological Advancements

Manufacturers of shutter strip making machines are often at the forefront of technological advancements. They continuously innovate to improve machine efficiency, reduce waste, and lower production costs. For instance, modern machines often employ programmable logic controllers (PLCs) and computer numerical control (CNC) technology, allowing for precise operations and adaptable production runs. This level of automation not only boosts output but also enhances the accuracy of the produced strips.

Moreover, some manufacturers have integrated Industry 4.0 principles into their machines, providing connectivity features that enable real-time monitoring and data collection. This aids in predictive maintenance, reducing downtime and operational disruptions. As manufacturers become increasingly competitive, the need for such technological integration has become essential.

The Importance of Customization

shutter strip making machine manufacturer

One of the critical roles of shutter strip making machine manufacturers is the ability to offer customized solutions tailored to specific business needs. Different applications may require unique specifications, so manufacturers often collaborate with clients to design machines that fulfill these requirements effectively. Whether it’s adjusting the width of the strips, altering the materials used, or enhancing the speed of production, customization is a vital aspect of the manufacturer’s service.

Sustainability and Environmental Responsibility

As global awareness of environmental issues grows, many shutter strip making machine manufacturers are taking steps to promote sustainable practices. This can include designing machines that use eco-friendly materials, reducing energy consumption, and implementing waste-reduction strategies during production. By adopting more sustainable methodologies, manufacturers not only contribute to environmental conservation but also enhance their appeal to environmentally conscious consumers.

The Competitive Market

The market for shutter strip making machines is highly competitive, with many manufacturers vying for market share. These manufacturers often differentiate themselves through quality, customer service, and technological features. Companies that establish strong relationships with their clients, providing reliable support and maintenance services, tend to gain a loyal customer base, further solidifying their position in the market.

Conclusion

In conclusion, shutter strip making machine manufacturers play a pivotal role in the manufacturing industry, particularly for businesses involved in the production of shutters and related products. Their contributions in terms of technological advancement, customization, and sustainability are crucial for meeting the evolving demands of the market. As the industry continues to grow, the importance of these manufacturers will undeniably increase, shaping the future of shutter production and, by extension, the wider manufacturing landscape. Efficient machines, along with innovation and sustainability, will remain the cornerstones of success in this specialized field.

-

Optimizing Your Production with CZ Purlin MachinesNewsMay.19, 2025

-

Maximizing Efficiency with C and U Channel Roll Forming MachinesNewsMay.19, 2025

-

Investing in Z Purlin MachinesNewsMay.19, 2025

-

Efficient Solutions with Metal Stud and Track Roll Forming MachinesNewsMay.19, 2025

-

Choosing the Best C Purlin MachinesNewsMay.19, 2025

-

Boost Your Production with Wall Angle Roll Forming MachinesNewsMay.19, 2025

-

Understanding Steel Coil Cutting Machines and Their ImportanceNewsMay.16, 2025