custom roofing roll forming machine

Custom Roofing Roll Forming Machine Revolutionizing the Roofing Industry

In the ever-evolving construction and roofing sectors, efficiency and precision remain paramount. This is where custom roofing roll forming machines come into play, offering innovative solutions that streamline the production of roofing materials. These machines are designed to create a variety of roofing profiles, tailored specifically to meet the unique demands of different projects.

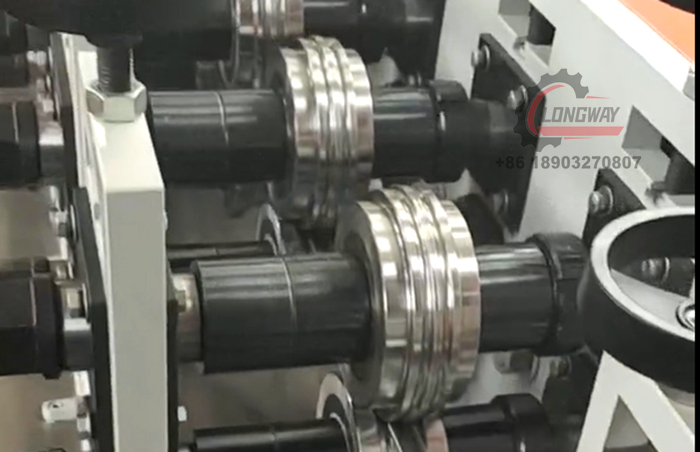

A custom roofing roll forming machine is engineered to produce metal sheets that can be transformed into various shapes and sizes, facilitating the creation of roofs that are not only structurally sound but also aesthetically pleasing. The process begins with a coil of raw metal sheet, which is unrolled and fed into the machine. As the metal passes through a series of rollers, it is gradually shaped into the desired profile. This process is highly customizable; companies can adjust the machine settings to produce different roofing styles, including standing seam, corrugated, and tile profiles.

One of the significant advantages of using a custom roofing roll forming machine is the ability to create on-demand materials. Instead of relying on pre-manufactured sheets that may not fit specific project requirements, construction companies can produce roofing materials that precisely match the specifications of a given job. This not only reduces waste but also significantly lowers costs associated with excess inventory and shipping.

custom roofing roll forming machine

In addition to customization, modern roll forming machines are equipped with advanced technology that enhances productivity and accuracy. Features such as computer numerical control (CNC) enable operators to input specific dimensions and angles, ensuring each piece produced meets exact standards. Furthermore, many machines integrate automatic cutting and punching functions, which streamline the production process, minimizing manual labor and reducing the likelihood of errors.

The versatility of custom roofing roll forming machines extends beyond just roofing applications. They can also be used to manufacture other metal components, such as gutter systems, soffits, and flashings, further cementing their place in the construction industry. This multi-functionality allows companies to invest in a single machine that can fulfill multiple production needs, making it a cost-effective solution.

Environmental considerations are increasingly important in construction, and custom roofing roll forming machines can contribute positively in this regard. By producing materials on-site, manufacturers can optimize the use of resources, reducing transport emissions and waste. Additionally, metal roofing offers long-term sustainability benefits, as it is often made from recyclable materials and boasts greater durability compared to traditional roofing materials.

In conclusion, custom roofing roll forming machines are invaluable tools in the modern construction landscape. They offer unparalleled customization, efficiency, and sustainability, enabling manufacturers to meet the specific needs of various roofing projects while minimizing waste and costs. As the demand for high-quality, tailored roofing solutions continues to grow, investing in such machinery is likely to become a standard practice, setting a new benchmark in the roofing industry. Whether for residential homes or large commercial buildings, the future of roofing is set to be shaped by these innovative machines.

-

Optimizing Your Production with CZ Purlin MachinesNewsMay.19, 2025

-

Maximizing Efficiency with C and U Channel Roll Forming MachinesNewsMay.19, 2025

-

Investing in Z Purlin MachinesNewsMay.19, 2025

-

Efficient Solutions with Metal Stud and Track Roll Forming MachinesNewsMay.19, 2025

-

Choosing the Best C Purlin MachinesNewsMay.19, 2025

-

Boost Your Production with Wall Angle Roll Forming MachinesNewsMay.19, 2025

-

Understanding Steel Coil Cutting Machines and Their ImportanceNewsMay.16, 2025