corrugated roof sheet machine price company

The Rise of Corrugated Roof Sheet Machine An Economic Perspective

In recent years, the construction and manufacturing industries have seen a significant shift towards more efficient and cost-effective building materials. Among these, corrugated roof sheets have gained immense popularity due to their durability, lightweight properties, and cost-effectiveness. As a result, the demand for corrugated roof sheet machinery has been steadily increasing, prompting various companies to invest in this technology. In this article, we will explore the factors influencing the price of corrugated roof sheet machines and what companies need to consider before making a purchase.

Understanding Corrugated Roof Sheets

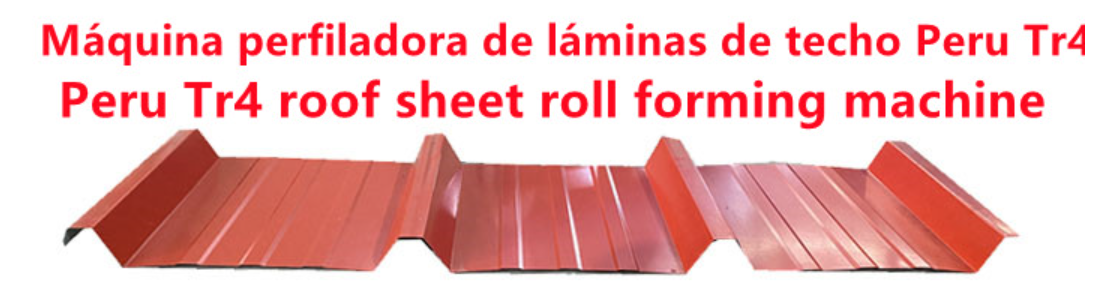

Before delving into the nuances of corrugated roof sheet machines, it's essential to understand what corrugated roof sheets are. Typically made from metal, plastic, or fiberglass, these sheets feature a wave-like pattern that enhances their structural integrity while making them lightweight and easy to handle. Their applications range from residential homes to large-scale industrial complexes, making them a versatile choice for builders.

The Role of Corrugated Roof Sheet Machines

Corrugated roof sheet machines are specialized pieces of equipment designed to manufacture these sheets efficiently. These machines can produce varying thicknesses and profiles of corrugated sheets in large quantities, meeting industrial demand. The design of the machine often includes multiple stages of forming, cutting, and finishing processes, which allows companies to produce high-quality roofing material quickly.

Factors Influencing the Price of Corrugated Roof Sheet Machines

1. Machine Specifications The price of a corrugated roof sheet machine is primarily determined by its specifications, such as production capacity, speed, and the complexity of the machine's design. More advanced machines, equipped with automation features and higher production capacities, tend to cost more.

2. Materials Used The type of materials used in the machine's construction and the parts involved also influence the price. Machines made from high-quality, durable materials will typically carry a higher price tag but offer greater longevity and performance.

corrugated roof sheet machine price company

3. Technology and Automation With the advent of advanced technology, many manufacturers are now providing machines with automated features that enhance efficiency and reduce labor costs. Investing in a fully automated corrugated roof sheet machine can lead to significant savings in the long run, albeit at a higher initial cost.

4. Supplier Reputation Established companies with a proven track record in manufacturing not only generally command higher prices but also offer better customer support, warranties, and maintenance services. Therefore, it’s prudent for businesses to consider the long-term value rather than just the upfront costs.

5. Market Demand Fluctuations in the construction market can lead to price variations in machinery. Increased demand for construction materials will raise prices, while a downturn may lead to price reductions. Keeping an eye on market trends can help businesses anticipate shifts in pricing.

Choosing the Right Company for Purchase

When considering the purchase of a corrugated roof sheet machine, it is crucial for companies to conduct thorough research. Prospective buyers should evaluate different suppliers based on their reputation, service offerings, and the technology used in their machines. Reading customer testimonials and seeking recommendations can also provide insight into the reliability and performance of the machines.

The Future of Corrugated Roof Sheet Machines

As the global construction industry continues to evolve, the demand for sustainable and efficient materials increases. Companies investing in corrugated roof sheet machines are poised to benefit from this trend, particularly those that adopt green technologies or efficient manufacturing practices. The future holds promising prospects for manufacturers capable of adapting to these changes.

Conclusion

In summary, the corrugated roof sheet machine industry is thriving, driven by an ever-increasing need for durable and cost-effective building materials. While the initial investment for a high-quality machine may seem steep, the long-term benefits in terms of production efficiency and quality can be substantial. Companies looking to invest in these machines should weigh the factors influencing price and consider the reputation of the suppliers to make informed decisions. As the market continues to develop, staying current with trends and innovations will be key to maintaining a competitive edge in the construction industry.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025