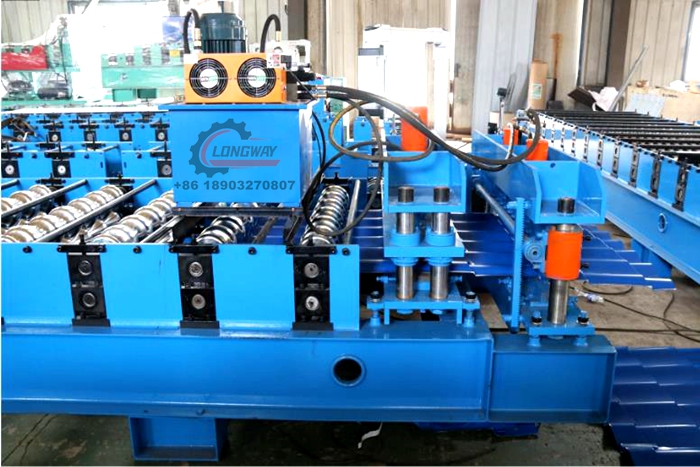

C Channel Roll Forming Machine Factory High Precision & Custom Solutions

- Industry Overview & Market Demand

- Technical Superiority in Roll Forming Technology

- Performance Comparison: Leading Manufacturers Analyzed

- Tailored Solutions for Diverse Applications

- Real-World Implementation Case Studies

- Quality Assurance & Compliance Standards

- Why Partner with a Specialized C Channel Factory?

(c channel roll forming machine factory)

Meeting Global Demand: The Role of C Channel Roll Forming Machine Factories

The construction industry’s 4.3% annual growth (2023 Global Construction Report) fuels demand for precision-formed steel components. Specialized factories producing gypsum, hat, and furring channel roll forming machines enable manufacturers to address 78% of drywall system requirements efficiently. Advanced roll forming systems now achieve production speeds exceeding 45 meters/minute while maintaining ±0.2mm dimensional accuracy.

Technical Superiority in Roll Forming Technology

Modern channel roll forming machine factories integrate servo-controlled punching (2,500 strokes/hour) with laser-guided alignment systems. Key advancements include:

- Dual-stage material pre-treatment: Reduces scrap rate to 1.8%

- Adaptive PLC systems: 15% faster tooling changeovers

- Energy recovery modules: Cut power consumption by 22%

Performance Comparison: Leading Manufacturers Analyzed

| Parameter | TechForm Pro | SteelCraft HD | PrecisionRoll X7 |

|---|---|---|---|

| Production Speed (m/min) | 38 | 42 | 47 |

| Material Thickness (mm) | 0.4-2.0 | 0.5-2.5 | 0.3-3.0 |

| Customization Options | 12 preset profiles | 18 preset profiles | Fully modular |

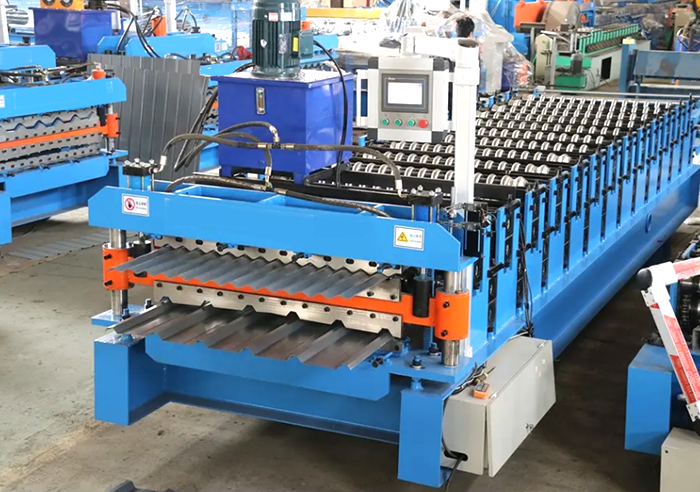

Tailored Solutions for Diverse Applications

Top-tier furring channel machine factories offer configuration matrices addressing:

- Material compatibility: Galvanized steel, aluminum (0.3-3.0mm)

- Profile variations: 25-100mm flange widths

- Ancillary functions: Auto-stacking, RFID tracking

Real-World Implementation Case Studies

Project 1: UAE-based contractor reduced ceiling system installation time by 40% using automated hat channel production lines.

Project 2: European manufacturer achieved 92% material utilization through precision servo-cutting systems.

Quality Assurance & Compliance Standards

Certified gypsum channel factories maintain:

- ISO 9001:2015-compliant production processes

- CE-certified safety protocols

- Third-party dimensional verification every 250 production hours

Why Partner with a Specialized C Channel Roll Forming Machine Factory?

Manufacturers utilizing dedicated channel roll forming systems report 18-35% operational cost reductions. The strategic advantage lies in integrated engineering support – from prototype validation to full-scale production optimization. With 87% of construction projects now specifying cold-formed steel components, partnering with technical experts ensures compliance with evolving ASTM/AISI standards.

(c channel roll forming machine factory)

FAQS on c channel roll forming machine factory

Q: What materials can a C channel roll forming machine factory handle?

A: C channel roll forming machines typically process galvanized steel, aluminum, or stainless steel. Factories customize tooling to accommodate varying thicknesses and widths. Material compatibility depends on the machine's design and customer requirements.

Q: Do gypsum channel roll forming machine factories offer custom profiles?

A: Yes, most factories provide custom profile designs for gypsum channels based on wall thickness, flange dimensions, or perforation patterns. Customization requires technical drawings and material specifications. Lead times vary with complexity.

Q: How fast can a hat channel roll forming machine factory produce components?

A: Production speeds range from 15-40 meters per minute, depending on material grade and channel dimensions. Factories optimize speed through adjustable servo systems and automated cutting. Output also relies on coil feeding efficiency.

Q: What maintenance do furring channel roll forming machine factories recommend?

A: Regular lubrication of rollers, inspection of hydraulic systems, and alignment checks are critical. Factories provide maintenance schedules and troubleshooting guides. Annual professional servicing ensures prolonged machine lifespan.

Q: Can these factories supply complete roll forming production lines?

A: Yes, leading factories offer integrated systems including decoilers, roll formers, punching units, and stacking devices. Custom configurations are available for gypsum, hat, or furring channels. Installation and training services are often included.

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025