Янв . 16, 2025 02:26

Back to list

metal sheet perforated machine

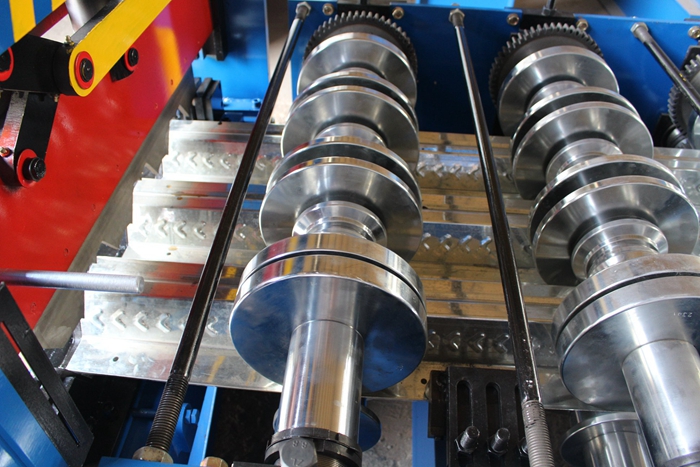

Z purlin machines have become an integral asset for manufacturers and builders looking to optimize structural components in construction projects. These advanced machines produce Z-shaped steel sections that are essential for roofing systems and structural supports. Their efficiency and precision make them a preferred choice among professionals seeking durability and cost-effectiveness.

Furthermore, adopting Z purlin machines inherently underscores a commitment to authoritative construction practices. This is evidenced by the machine's ability to manufacture structural components that adhere to stringent industry standards. The quality assurance processes integrated within the machine system prevent deviations from design requirements, ensuring that each output meets the structural integrity demanded by contemporary architectural designs. Trustworthiness in Z purlin machines is reinforced by the transparent operational processes they offer. From material input to the final product, each phase is meticulously overseen, allowing stakeholders to monitor quality control measures effectively. This traceability is a key consideration for construction managers aiming to uphold the highest standards of safety and performance in their projects. From an environmental standpoint, using a Z purlin machine also aligns with sustainable building practices. These machines are designed to minimize material waste, promoting resource efficiency in line with green construction principles. Consequently, they support builders not only in achieving economic objectives but also in advancing societal goals related to environmental stewardship. In conclusion, choosing a Z purlin machine offers a composite of efficiency, expertise, and reliability backed by real-world experience. The capability to deliver consistent, high-quality results places these machines at the forefront of industrial construction solutions. Builders and manufacturers relying on these machines can trust that they're using tools that embrace technological innovation while meeting and exceeding industry standards for structural component production. Such assurance is invaluable in the demanding arena of modern construction, where precision and dependability are non-negotiable.

Furthermore, adopting Z purlin machines inherently underscores a commitment to authoritative construction practices. This is evidenced by the machine's ability to manufacture structural components that adhere to stringent industry standards. The quality assurance processes integrated within the machine system prevent deviations from design requirements, ensuring that each output meets the structural integrity demanded by contemporary architectural designs. Trustworthiness in Z purlin machines is reinforced by the transparent operational processes they offer. From material input to the final product, each phase is meticulously overseen, allowing stakeholders to monitor quality control measures effectively. This traceability is a key consideration for construction managers aiming to uphold the highest standards of safety and performance in their projects. From an environmental standpoint, using a Z purlin machine also aligns with sustainable building practices. These machines are designed to minimize material waste, promoting resource efficiency in line with green construction principles. Consequently, they support builders not only in achieving economic objectives but also in advancing societal goals related to environmental stewardship. In conclusion, choosing a Z purlin machine offers a composite of efficiency, expertise, and reliability backed by real-world experience. The capability to deliver consistent, high-quality results places these machines at the forefront of industrial construction solutions. Builders and manufacturers relying on these machines can trust that they're using tools that embrace technological innovation while meeting and exceeding industry standards for structural component production. Such assurance is invaluable in the demanding arena of modern construction, where precision and dependability are non-negotiable.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products