Roll Forming Machine for Wall Panel Production and Customization Solutions

Wall Panel Roll Forming Machine Transforming the Construction Industry

In the ever-evolving landscape of construction technology, the wall panel roll forming machine has emerged as a pivotal innovation, revolutionizing the production of building materials. This advanced machinery is specifically designed to create high-quality wall panels, which are essential components in modern architectural designs. With the increasing demand for efficient and cost-effective building solutions, the wall panel roll forming machine offers significant advantages to manufacturers and builders alike.

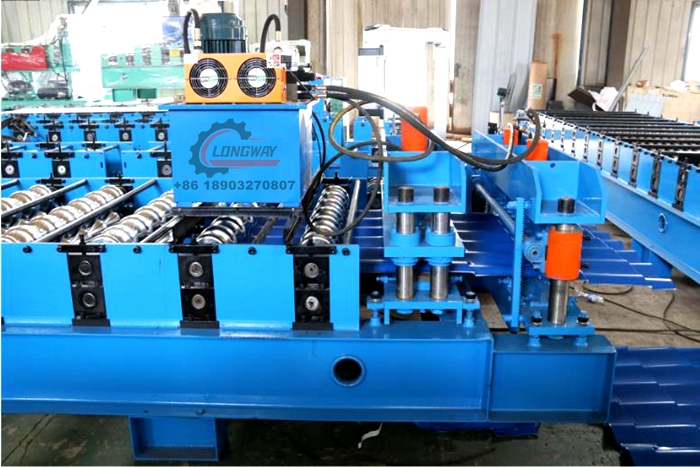

A wall panel roll forming machine operates by continuously feeding metal sheets into a series of rollers. These rollers shape the sheets into desired profiles that can be used for walls, roofs, and various structural elements. The precision and automation of this machine facilitate the rapid production of panels, enabling manufacturers to meet tight deadlines while maintaining high standards of quality. The resulting panels are not only durable and lightweight but also customizable to suit specific architectural needs, allowing for a diverse range of applications.

One of the most notable benefits of using a wall panel roll forming machine is its efficiency. Traditional methods of producing wall panels can be time-consuming and labor-intensive, requiring significant manual intervention. In contrast, roll forming technology streamlines this process, significantly reducing production time. Moreover, the machine's capability to handle various materials—including steel, aluminum, and other alloys—makes it versatile, catering to different market demands and preferences.

wall panel roll forming machine

Another compelling advantage is the cost-effectiveness of the production process. By automating panel formation, manufacturers can lower labor costs and minimize material waste—a significant factor in today’s environmentally-conscious market. Furthermore, the uniformity and quality of the panels produced lead to reduced installation time on construction sites, further enhancing overall project efficiency.

In addition, the aesthetic appeal of wall panels produced by roll forming machines cannot be overlooked. With options for various finishes, colors, and textures, these panels can elevate the visual aspects of any building project. Architects and designers appreciate the flexibility provided by roll-formed panels, allowing for creative solutions that can differentiate a project in a competitive landscape.

As the construction industry continues to embrace modernization, the wall panel roll forming machine is set to play a crucial role in shaping the future. Its ability to produce high-quality, cost-effective, and aesthetically pleasing wall panels positions it as a staple in the toolkit of manufacturers and builders aiming to meet the demands of contemporary construction projects. Investing in a wall panel roll forming machine is not just a business decision; it is a commitment to innovation, efficiency, and excellence in the building industry.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025