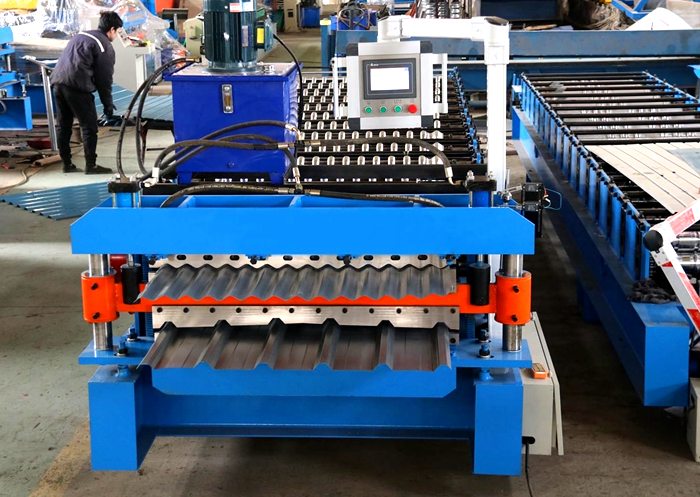

pedal plate roll forming machine

The Pedal Plate Roll Forming Machine A Revolution in Manufacturing

In the modern manufacturing landscape, efficiency and precision have become paramount. Among the myriad of machines that facilitate these goals, the pedal plate roll forming machine stands out due to its unique design and capabilities. This article explores the functionality, benefits, and applications of the pedal plate roll forming machine, shedding light on why it is an essential component in various production lines.

Understanding Roll Forming

Roll forming is a process that involves the continuous bending of a long strip of metal into a desired cross-sectional profile. Setting the foundation for this technique, the pedal plate roll forming machine uses a series of specially designed rolls to shape sheet metal into pedal plates—components often found in automotive and machinery applications. The machine is designed to handle various materials, including steel, aluminum, and other metals, making it highly versatile.

Key Features and Functionality

1. High Precision One of the significant advantages of a pedal plate roll forming machine is the precision it offers. With advanced computer numeric control (CNC) systems, manufacturers can achieve intricate designs with tight tolerances, ensuring that each produced pedal plate meets exact specifications.

2. Continuous Production The nature of roll forming allows for continuous processing of metal, leading to higher production rates compared to traditional stamping methods. This continuous flow not only increases efficiency but also reduces labor costs — a critical factor in competitive manufacturing environments.

3. Customizability The versatility of the pedal plate roll forming machine is evident in its ability to produce custom shapes and sizes. Manufacturers can easily adjust the roll setups to create specific profiles based on customer requirements, making the machine suitable for a wide range of industries.

4. Durability and Longevity Built with robust materials and components, the pedal plate roll forming machine is designed for longevity. Its reliable performance ensures less downtime, making it a valuable investment for manufacturers.

pedal plate roll forming machine

Benefits to Manufacturers

The adoption of a pedal plate roll forming machine can significantly enhance a manufacturer’s operations. By streamlining production processes, companies can reduce material waste and lower energy consumption. Additionally, the machine’s ability to work with various metals allows manufacturers to expand their product lines without substantial investment in new machinery.

Furthermore, the equipment’s precision minimizes the need for secondary operations, such as trimming and finishing, leading to cost savings and faster turnaround times. In industries where speed and efficiency are crucial, such as automotive manufacturing, these advantages create a competitive edge.

Applications Across Industries

The pedal plate roll forming machine is indispensable across several sectors. In the automotive industry, it is used to create components such as floor pans, brackets, and pedal assemblies. Additionally, the machinery finds applications in the manufacture of heavy equipment, where robust and durable pedal plates are required.

Moreover, the construction industry benefits from roll-formed pedal plates for scaffolding, support structures, and architectural elements. As manufacturers continuously seek ways to innovate and improve their processes, the pedal plate roll forming machine represents a commitment to quality and efficiency in production.

Conclusion

In summary, the pedal plate roll forming machine embodies the evolution of manufacturing technology, blending precision, efficiency, and adaptability. Its ability to produce high-quality components with minimal waste makes it a vital tool in various industries. As the manufacturing sector continues to grow and evolve, machines like the pedal plate roll forming machine will play a crucial role in shaping the future of production, helping companies meet the demands of tomorrow while keeping costs in check. Investing in such technology is not just a commitment to quality; it is a step toward a more sustainable and efficient manufacturing process.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025